Furnace building system with compact kiln lining

A kiln lining and furnace building technology, applied in the direction of lining repair, etc., can solve the problems of decreased service life of furnace lining, weakened strength, poor uniformity of furnace building, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

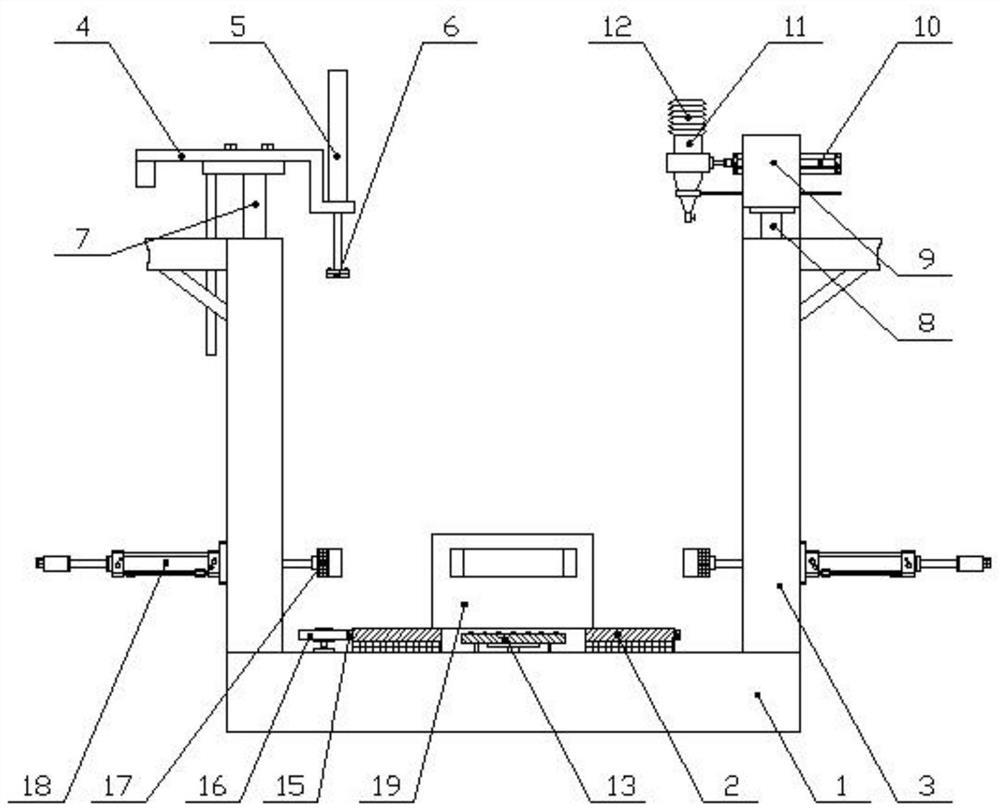

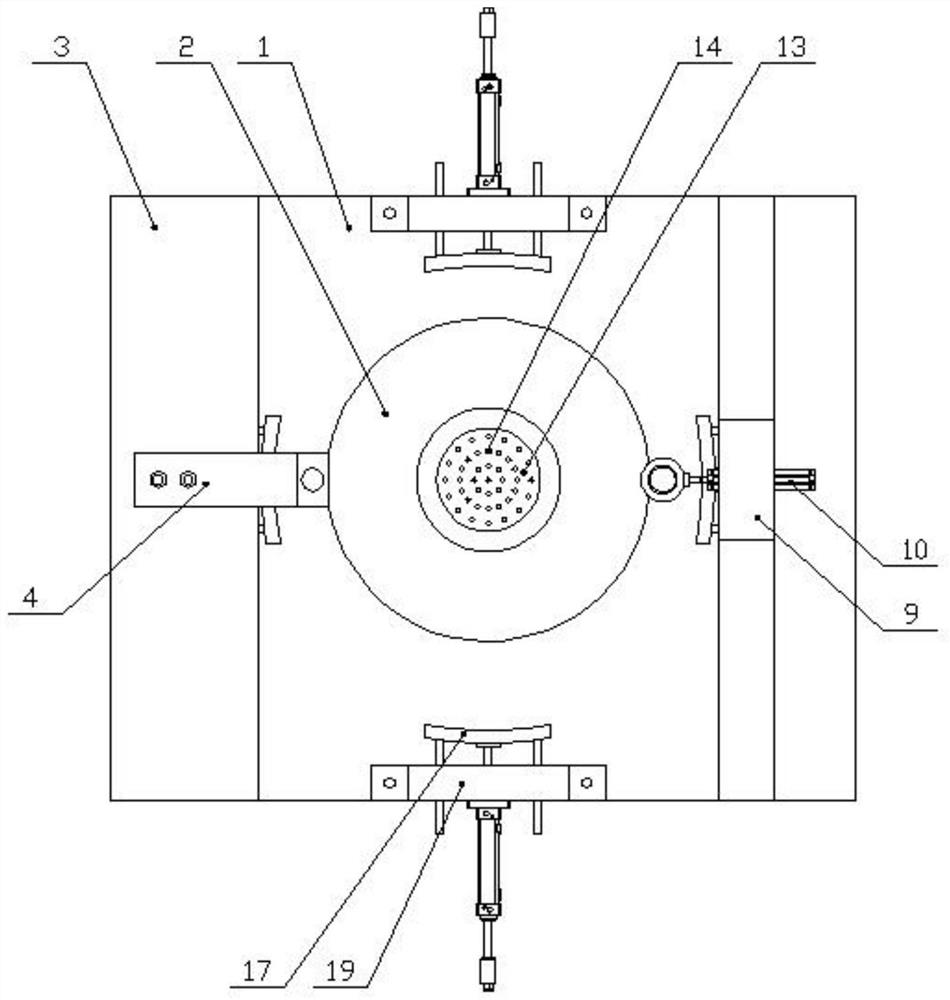

[0020] Example 1, such as Figure 1-Figure 2 As shown, the specific structure of this embodiment is as follows: it includes a base 1, a feeding mechanism, and a tamping mechanism. The middle part of the upper end of the base 1 is provided with a bearing plate 2 with a horizontal upper end surface, and the bearing plate 2 rotates around its vertical axis. The upper end of the base 1 is provided with a support frame 3 on the outside of the carrier plate 2. In this embodiment, there are two support frames 3 at intervals on the left and right. The gap between the support frames 3 is convenient for hoisting the kiln to the carrier plate 2; Described building tamping mechanism comprises installation frame 4, ramming driving device 5, ramming part 6, and described installation frame 4 is arranged on support frame 3 top, and vertical drive part 7 is vertically arranged in one side support frame 3, vertically The driving part 7 can adopt an oil cylinder, etc., and the piston rod of the...

Embodiment 2

[0022] Example 2, such as Figure 1-2 As shown, other structures of the present embodiment are the same as those of Embodiment 1, but in the present embodiment, a feeding vertical pusher 8 is provided on the other side support frame 3 opposite to the tamping mechanism, and the feeding vertical pusher 8 can be Adopt oil cylinder etc., described feeding vertical pushing part 8 is connected with lifting part 9 in feeding mechanism, and lifting part 9 is arranged in the storage groove of support frame 3, and described lifting part 9 is provided with feeding horizontal pushing part 10, and feeding The horizontal pushing part 10 can adopt an electric push rod, a cylinder, etc., and the feeding horizontal pushing part 10 is connected with the lower hopper 11 in the feeding mechanism. 12 can use hoses, telescopic tubes, etc.; the mounting bracket 4 and the bottom plate are connected by bolts, and threaded holes are arranged on the bottom plate at radial intervals along the bearing pla...

Embodiment 3

[0024] Example 3, such as Figure 1-2 As shown, the other structures of this embodiment are the same as those of Embodiment 1, but in this embodiment, the carrying plate 2 is ring-shaped, and the middle part of the carrying plate 2 is provided with a jacking portion 13 that moves in the vertical direction, and the base 1 An oil cylinder for driving the lifting part 13 is arranged inside, and the upper end of the lifting part 13 is provided with a universal wheel 14; the outer side of the carrying plate 2 is provided with a centering plate 17 moving in the horizontal direction in a circular array of its axes, The centering plate 17 is arc-shaped, and its center of circle is located on one side of the carrier plate 2. In this embodiment, there are four centering plates 17, and the angle between any two of them is 90 degrees. The centering plate 17 and the Horizontal promotion oil cylinder 18 is connected, and the horizontal promotion oil cylinder 18 that is arranged on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com