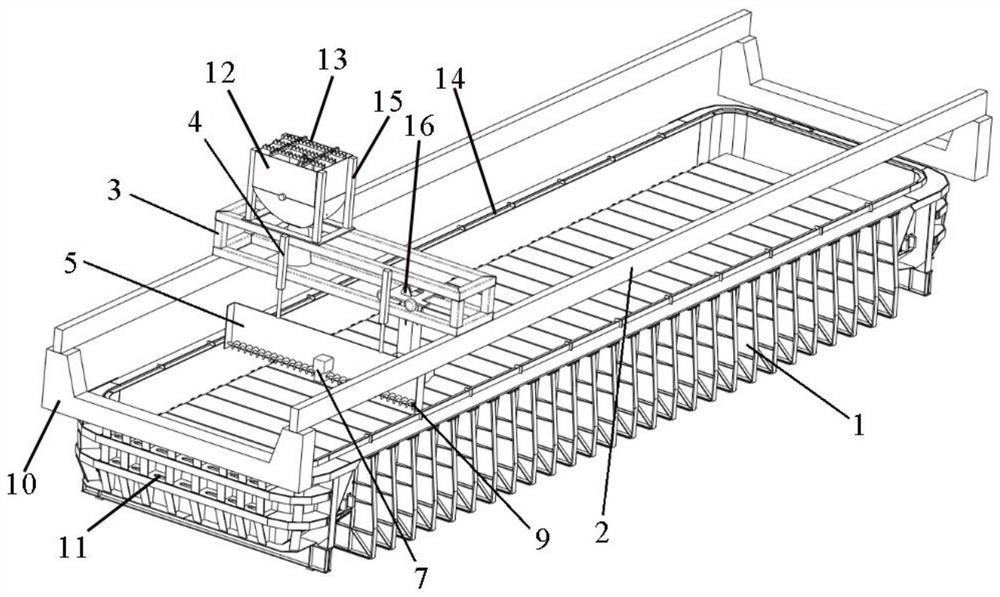

Aluminum electrolysis cell lining integral forming slicking device

An integral molding, aluminum electrolytic cell technology, applied in the field of aluminum electrolytic intelligent equipment, to achieve the effect of filling the gap in the industry, real-time efficient paving and scraping operations, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

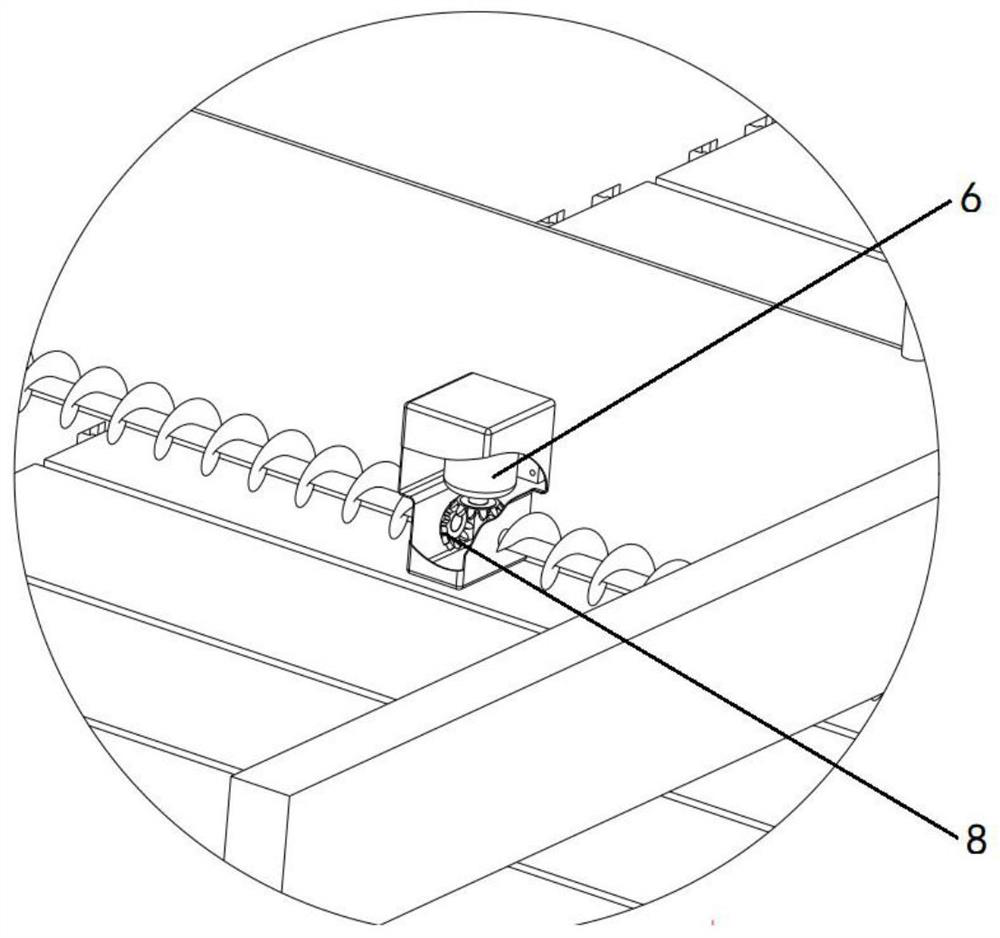

[0016] Such as figure 1 and figure 2 As shown, the present invention is constituted as follows: including electrolytic cell 1, fixed frame, 2, moving frame 3, lifting device 4, material blocking plate 5, motor 6, protective cover 7, gear pair 8, shaft screw 9 and other structures composition. In addition, it also includes a fixed frame support beam 10 and a silo 12, the silo 12 is used to fill the compacted paste; the silo 12 is provided with a silo support 15, which is used for the connection of the silo 12, and the connection method is welding; the silo 12 is designed There are bag opening teeth 13, which are used to cut the compacted paste transfer bag; it also includes the inner tank shell 14 of the electrolytic cell, and the inner cavity of the electrolytic cell 1 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com