Electromagnetic Control Method of Mold Flow Field Used in Slab Continuous Casting Production

An electromagnetic control and crystallizer technology, applied in the field of crystallizer control, can solve the problems such as the inability to effectively improve the non-metallic inclusions of the crystallizer and the floating conditions of bubbles, the limitation, and the reduction of the impact depth of the spit stream from the side hole of the nozzle, etc. Excellent electromagnetic flow control effect, flexible operation, and the effect of improving floating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

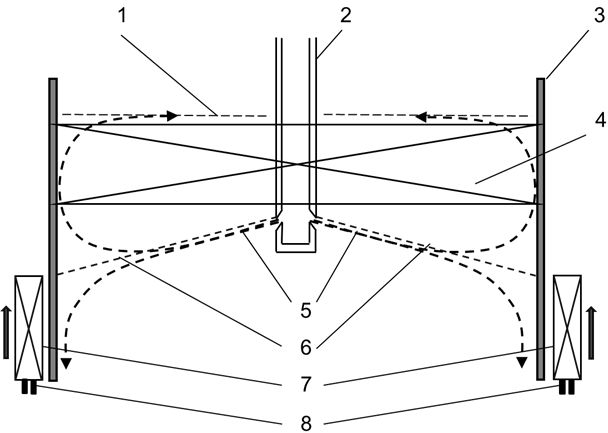

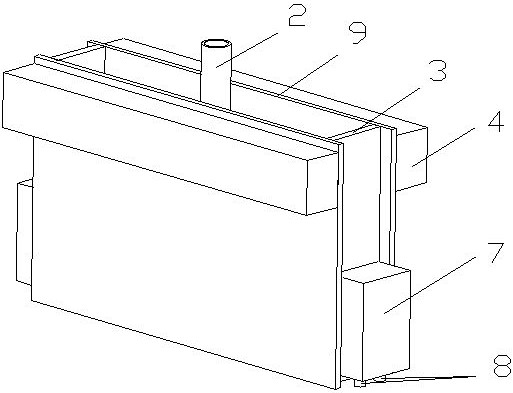

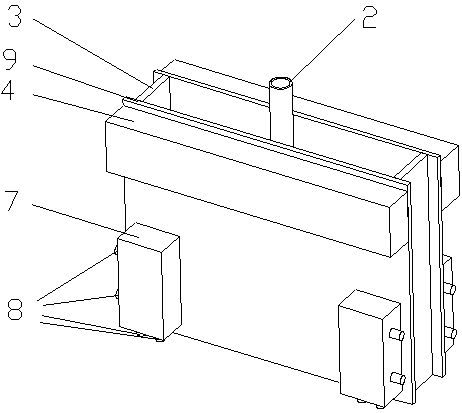

[0029] Production conditions: production of IF steel plates with a casting speed of 1.6m / s, a width of 1450mm, and a thickness of 230mm, the insertion depth of the nozzle (that is, the distance from the meniscus to the upper edge of the nozzle) is 190mm, the outer diameter of the nozzle is 80mm, and the inclination angle with its own axis is 75° . For this working condition, the method of the present invention is used to simultaneously use electromagnetic stirrers in multiple parts of the crystallizer to reasonably adjust the flow field in the crystallizer.

[0030] The iron core height of the mold electromagnetic stirrer is installed along the upper part of the wide surface of the crystallizer. The height of the iron core is 150mm. The installation position is between the upper edge of the nozzle outlet and the meniscus. The coverage ratio of the effective stirring area is greater than 0.75. Install two electromagnetic stirring devices along the lower part of the narrow side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com