Control method of continuous casting of different steel grades

A control method and technology of different steel types, applied in the field of metallurgical continuous casting, can solve the problems of not reducing the billet volume, increasing the amount of molten steel, and easily producing joint marks, so as to improve the continuous casting process of different steel types and reduce the The degree of mixing, the effect of reducing the fluctuation of casting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]The steel grades of the heats before and after the present embodiment are respectively MR T2(3)-BA and MR T-4CA, and the casting cross-sections of both streams are 1000mm, and the corresponding steel grade compositions are as follows:

[0051] The mass percent of MR T2(3)-BA composition is:

[0052] C:0.068-0.094; Si≤0.034; Mn:0.35-0.45; Cr:0.03-0.05; O≤0.004;

[0053] The rest is Fe and inevitable impurity elements.

[0054] The mass percentage of MR T-4CA composition is:

[0055] C:0.026-0.054; Si≤0.034; Mn:0.18-0.28; Cr≤0.05;

[0056] The rest is Fe and inevitable impurity elements.

[0057] : the steps of this embodiment are:

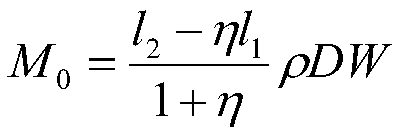

[0058] ①When the molten steel level reaches the height of the dam, the corresponding M=20t, take l 1 = 2m, l 2 =6m, η=0.25, then calculate the remaining steel amount M of the previous steel type according to the formula 0 for:

[0059]

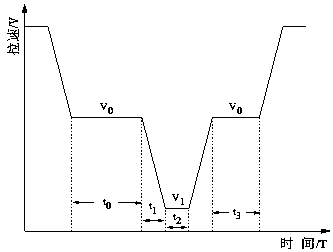

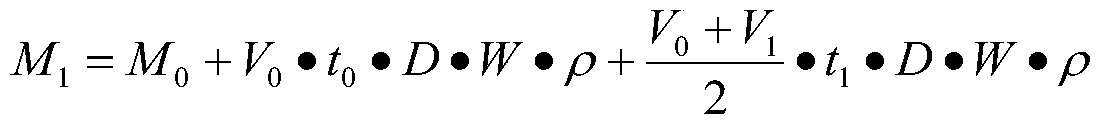

[0060] ②Slab thickness D=0.23m, V 0 =0.8m / min, V 1 = 0.4m / min, t 0 = 3.5min, t 1 =50s, then ...

Embodiment 2

[0078] The steel grades of the heats before and after this embodiment are T5-5 and SAE1022 respectively, and the casting cross-sections of both streams are 1090mm, and the corresponding steel grade components are as follows:

[0079] The mass percentage of T5-5 composition is:

[0080] C; 0.115-0.145; Si≤0.034; Mn:0.25-0.35; N≤0.0045; Nb≤0.002; V≤0.005;

[0081] The rest is Fe and inevitable impurity elements.

[0082] The mass percentage of SAE1022 composition is:

[0083] C: 0.18-0.22; Si≤0.054; Mn: 0.85-1; Nb≤0.007; V≤0.007; Ti≤0.007;

[0084] The rest is Fe and inevitable impurity elements.

[0085] The steps of this embodiment are:

[0086] ①When the molten steel level reaches the height of the dam, the corresponding M=20t, take l 1 = 2m, l 2 =6m, η=0.3, then calculate the remaining steel amount M of the previous steel type according to the formula 0 for:

[0087]

[0088] ②Slab thickness D=0.23m, V 0 =0.8m / min, V 1 = 0.4m / min, t 0 = 4min, t 1 =50s, then th...

Embodiment 3

[0106] The steel grades of the heats before and after this embodiment are Q345B and S245 respectively, and the casting cross-sections of both streams are 1530mm, and the corresponding steel grades are as follows:

[0107] The mass percentage of Q345B composition is:

[0108] C:0.12-0.16; Si:0.15-0.25; Mn:1.1-1.2; N≤0.006; V≤0.014; Ti:0.025-0.035; Cr≤0.03;

[0109] The rest is Fe and inevitable impurity elements.

[0110] The mass percentage of S245 composition is:

[0111] C: 0.075-0.125; Si: 0.11-0.2; Mn: 0.9-1.1; N≤0.009; V≤0.007; Ti≤0.007; Cr≤0.05;

[0112] The rest is Fe and inevitable impurity elements.

[0113] The steps of this embodiment are:

[0114] ①When the molten steel level reaches the height of the dam, the corresponding M=20t, take l 1 = 2m, l 2 =6m, η=0.45, then calculate the remaining steel amount M of the previous steel type according to the formula 0 for:

[0115]

[0116] ②Slab thickness D=0.23m, V 0 =0.8m / min, V 1 = 0.4m / min, t 0 = 5min, t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com