A vertical electromagnetic braking device for controlling the flow of molten steel in a continuous casting mold

A technology of continuous casting crystallizer and electromagnetic braking, which is applied in the field of continuous casting to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

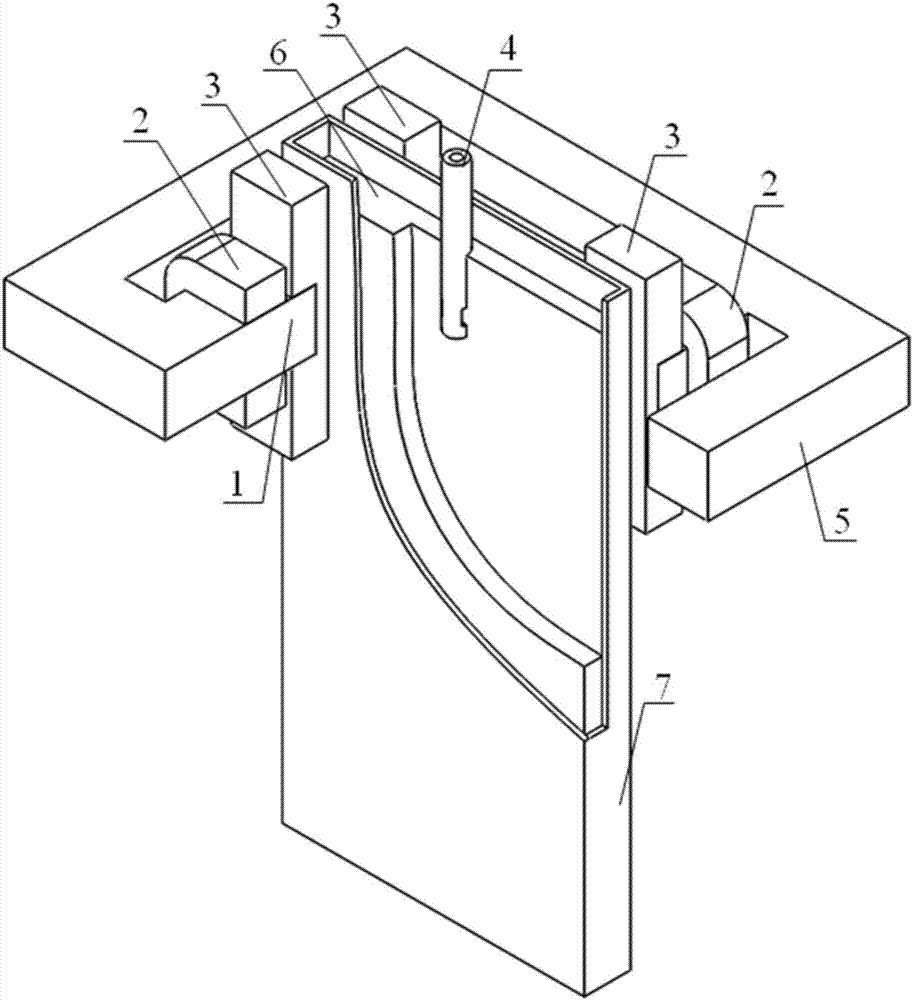

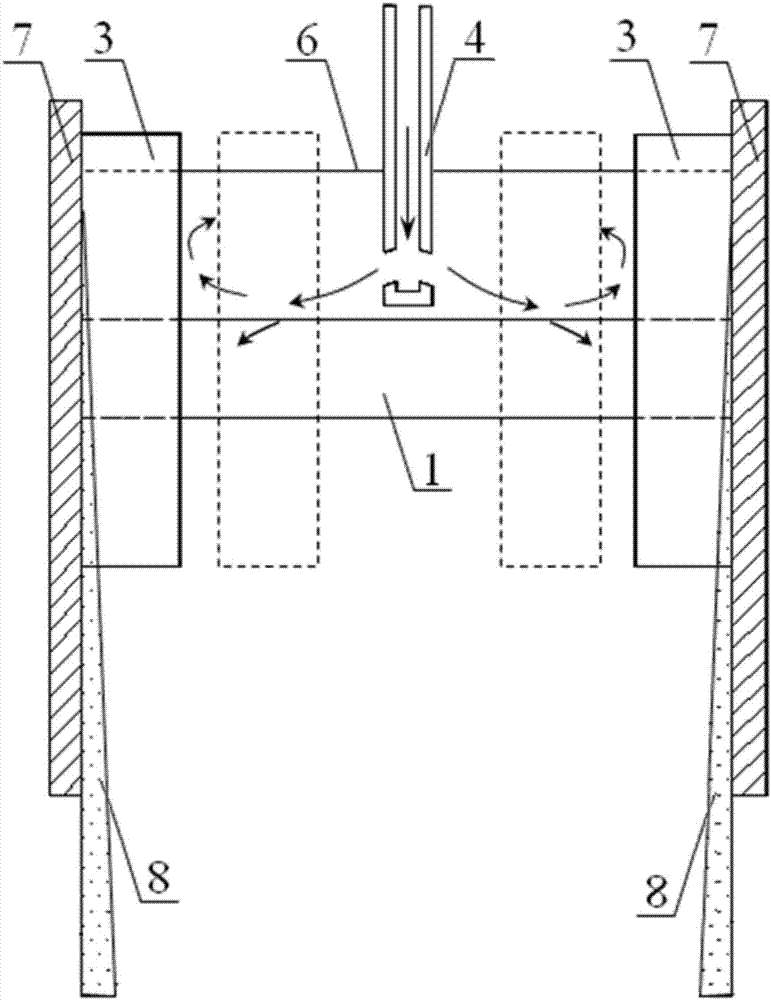

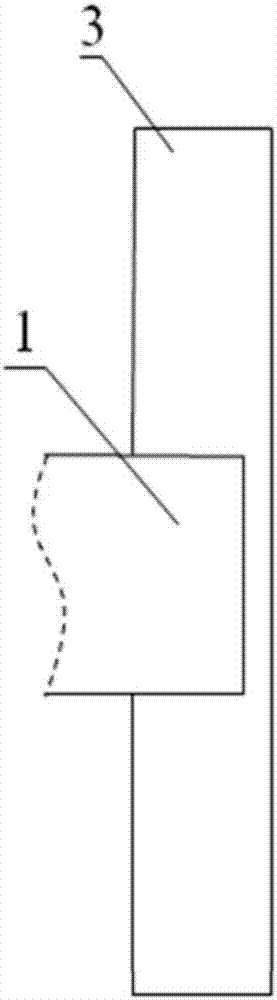

[0087] In this example, using figure 1 In the vertical electromagnetic braking device shown, the vertical magnetic pole 3 and the horizontal magnetic pole 1 adopt the connection method in Figure 3(a), and the vertical magnetic pole 3 covers the side of the mold 7 in height from the molten steel surface 6 area to the intrusive nozzle 4 The impact point of the molten steel and the area below the horizontal magnetic pole 1, the cross-sectional size of the crystallizer 7 is 300mm×50mm, and the height of the vertical magnetic pole 3 is 240mm.

[0088] The currents of 700A and 1050A are respectively applied to the excitation coil 2 of the horizontal magnetic pole 1, and the magnetic field distribution diagram of the vertical magnetic pole center along the height direction of the center section of the side of the crystallizer is shown as Figure 7 shown.

[0089] Depend on Figure 7 It can be seen that with the increase of current intensity, the magnetic induction intensity gradual...

Embodiment 2

[0091] In this example, using figure 1 In the vertical electromagnetic braking device shown, in order to observe the fluctuation of the liquid level in the crystallizer 7 more intuitively, the test object is the metal liquid of the low melting point alloy SnPbBi; the vertical magnetic pole 3 and the horizontal magnetic pole 1 adopt the Connection method, the vertical magnetic pole 3 covers the side of the mold 7 in height, from the molten steel surface 6 area to the impact point of the intrusive nozzle 4 outflowing molten steel and the area under the horizontal magnetic pole 1, the thickness of the mold 7 is 100mm, and the mold The half width of 7 is 600mm, the height of vertical magnetic pole 3 is 440mm, the inclination angle of the side hole of intrusive nozzle 4 is -15°, the intrusion depth of intrusive nozzle 4 is 100mm, and the casting speed is 1.27m / min.

[0092] Apply current to the excitation coil 2 of the horizontal magnetic pole 1, so that a magnetic field of about 0...

Embodiment 3

[0095] In this example, using figure 1 In the vertical electromagnetic braking device shown, the vertical magnetic pole 3 and the horizontal magnetic pole 1 adopt the connection method in Figure 3(c), then the height of the vertical magnetic pole 3 below the horizontal magnetic pole 1 is 0mm, and the vertical magnetic pole 3 covers the height The side of the mold 7 is from the area 6 of the molten steel surface to the impact point of the molten steel flowing out of the intrusive nozzle 4 and the area above the horizontal magnetic pole 1. The cross-sectional size of the mold 7 is 1400mm×230mm, and the inclination angle of the side hole of the intrusive nozzle 4 is - 15°, the penetration depth of the intrusive nozzle 4 is 170mm, and the casting speed is 1.6m / min.

[0096] A current of 850A is applied to the excitation coil 2 of the horizontal magnetic pole 1, and the internal magnetic field distribution diagram of the molten steel in the mold 7 is as follows Figure 9 As shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com