Multiple-unit control method and multiple-unit control device for reverse laser shot peening

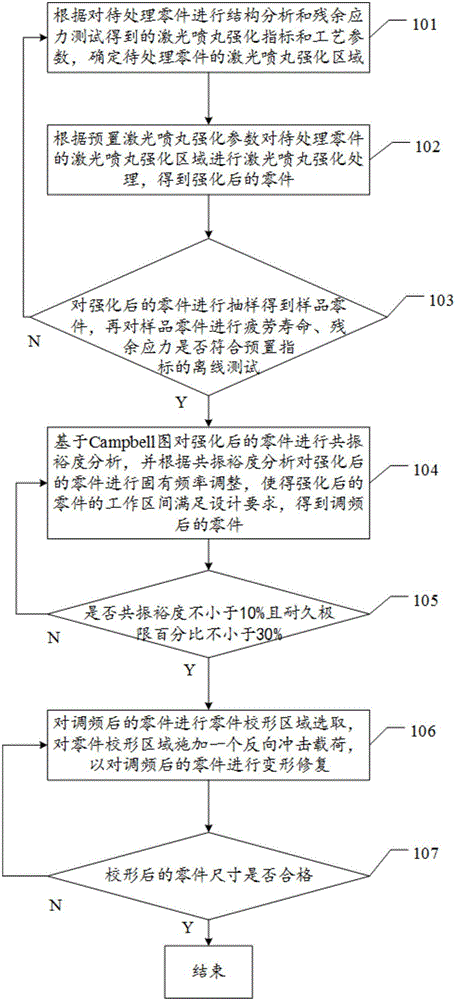

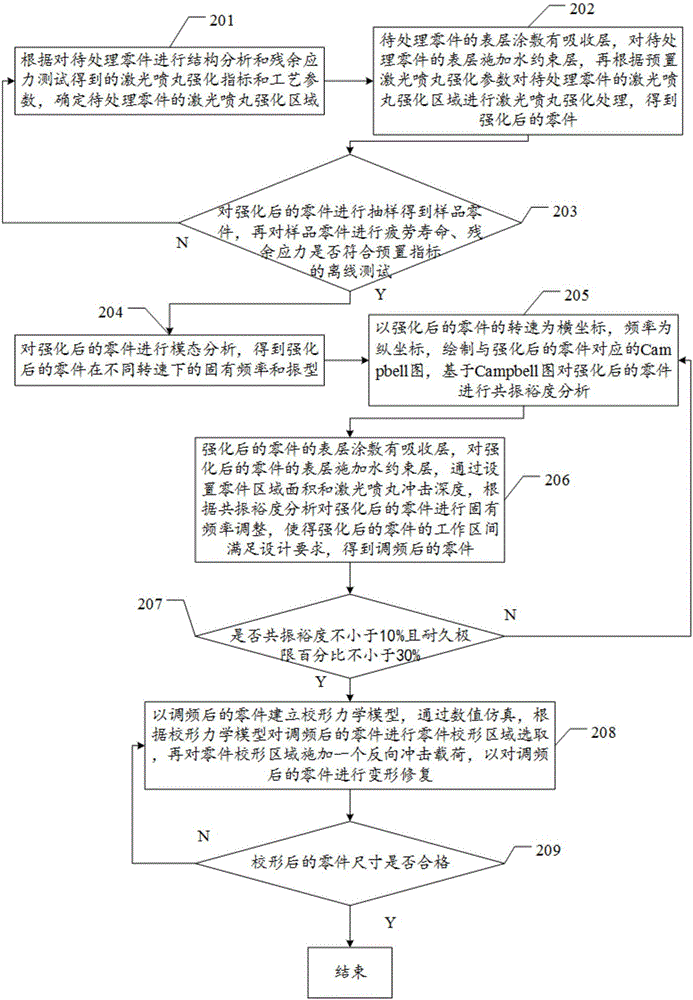

A technology of laser peening and multiple control, applied in the direction of electrical program control, program control in sequence/logic controller, etc., can solve the problems of intensification, frequency modulation and shape correction process out of sync

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

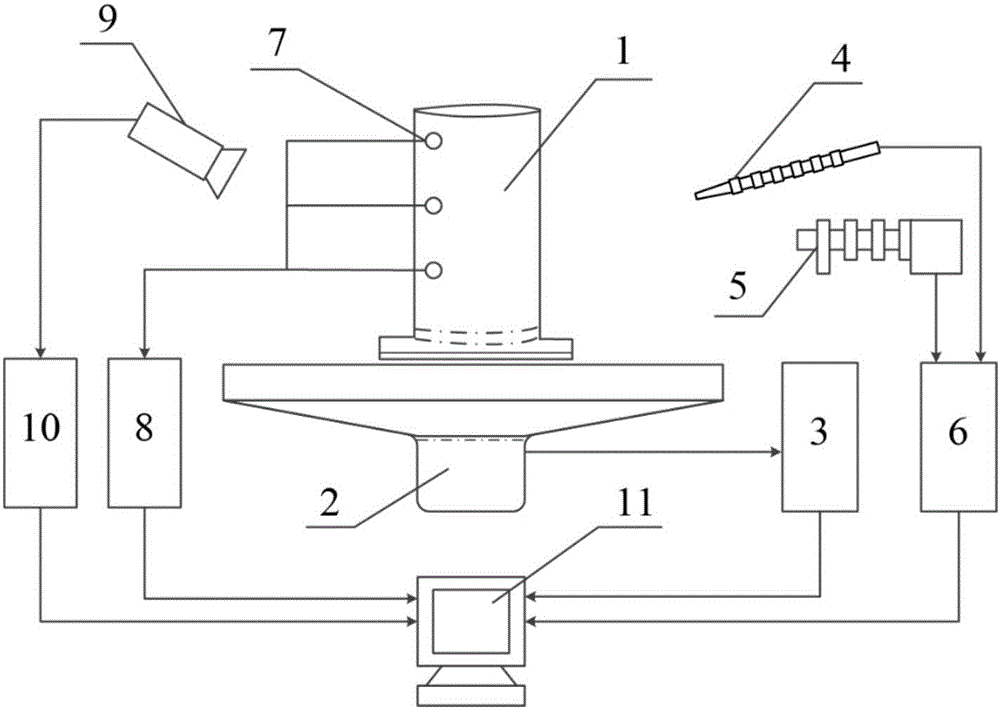

Method used

Image

Examples

Embodiment Construction

[0053] The embodiment of the present invention provides a reverse laser peening multi-component control method and device, which overcomes the problem of asynchronous strengthening, frequency modulation and shape correction of existing high-speed rotating parts, and uses laser shot peening to strengthen, frequency modulation and shape correction Ability to realize multiple processing of parts, improve structural fatigue life, and ensure resonance margin within the working speed of parts.

[0054] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the following The described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com