Method and device for strengthening fastening hole by shocking with ring laser

A technology of laser shock strengthening and fastening holes, which is applied in the direction of heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of unfavorable continuous operation, small impact force of hole wall, and increased surface roughness of materials, etc., to achieve the benefit of continuous operation , Improve fatigue life, not easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

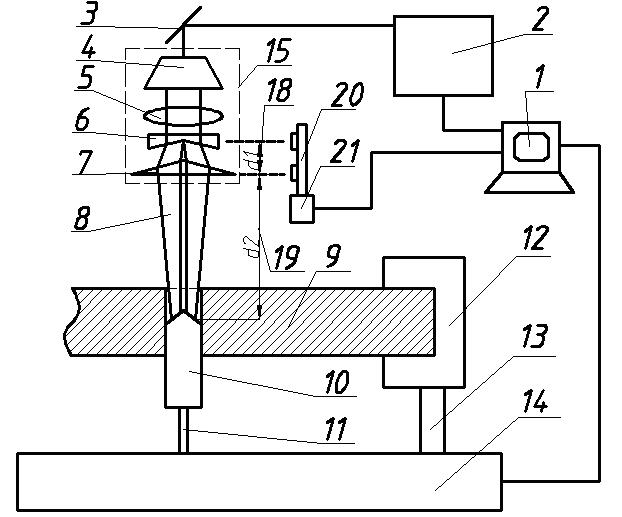

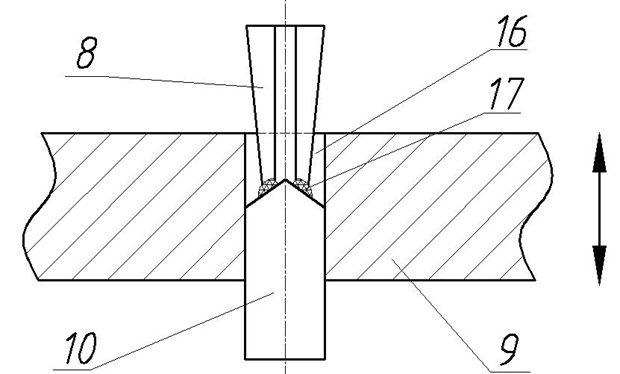

[0022] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the figures.

[0023] The laser shock strengthening device for fastening holes of the present invention includes: computer 1, high-power pulse laser 2, 45° total reflection mirror 3, spot adjustment device 15, energy absorption rod 10, feed mechanism A11, clamp 12, feed Mechanism B13, workbench 14, guide rail 20, stepping motor 21, water spray device; Described spot adjusting device 15 comprises: beam expander mirror 4, converging lens 5, conical lens A6, conical lens B7; Spot adjusting device 15 is located at Directly above the workbench 14, the feed mechanism A11 is set in the middle of the workbench 14, and the feed mechanism B13 is set on one side of the workbench 14. The feed mechanism A11 and the feed mechanism B13 are provided with clamps, and the energy absorption rod 10 is installed on the feeder. On the fixture for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com