Low-cost multi-component heat-resistant magnesium alloy and preparation method of magnesium alloy

A magnesium alloy, low-cost technology, applied in the field of metal materials, can solve the problems of high cost of alloys that limit wide application, damage mechanical properties, increase alloy prices and other problems, achieve simple melting and heat treatment processes, improve high-temperature properties, alloy mechanical properties and The effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

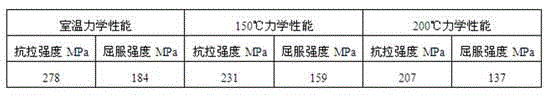

Embodiment 1

[0020] A low-cost multi-component heat-resistant magnesium alloy, the components and their weight percentages are: Al is 4.85%, Zn is 0.82%, Sr is 0.74%, Ca is 0.46%, Sn is 1.23%, Sb is 1.27%, Mn is 0.26%, Bi is 0.38%, Si is 0.84%, and the balance is Mg;

[0021] A method for preparing a heat-resistant magnesium alloy as described above, comprising the following steps:

[0022] 1) Weigh pure magnesium ingots, pure aluminum ingots, pure zinc particles, Mg-Sr master alloys, Mg-Ca master alloys, pure tin particles, pure antimony, Al-Mn master alloys, pure bismuth and Al- Si master alloy, spare;

[0023] 2) The pure magnesium ingot, pure aluminum ingot, pure zinc grain, Mg-Sr master alloy, Mg-Ca master alloy, pure tin grain, pure antimony, Al-Mn master alloy, pure bismuth and Al -Si master alloys were dried and preheated at 180°C for 2.5 hours, and set aside;

[0024] 3) Put the preheated pure magnesium ingots, pure aluminum ingots, pure zinc particles, pure tin particles, pure...

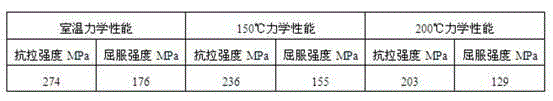

Embodiment 2

[0027] A low-cost multi-component heat-resistant magnesium alloy, the components and their weight percentages are: Al is 5.26%, Zn is 1.12%, Sr is 0.78%, Ca is 0.61%, Sn is 1.43%, Sb is 0.87%, Mn is 0.17%, Bi is 0.29%, Si is 0.57%, and the balance is Mg;

[0028] A method for preparing a heat-resistant magnesium alloy as described above, comprising the following steps:

[0029] 1) Weigh pure magnesium ingots, pure aluminum ingots, pure zinc particles, Mg-Sr master alloys, Mg-Ca master alloys, pure tin particles, pure antimony, Al-Mn master alloys, pure bismuth and Al- Si master alloy, spare;

[0030] 2) The pure magnesium ingot, pure aluminum ingot, pure zinc grain, Mg-Sr master alloy, Mg-Ca master alloy, pure tin grain, pure antimony, Al-Mn master alloy, pure bismuth and Al -Si master alloys were dried and preheated at 185°C for 3 hours, and set aside;

[0031] 3) Put the preheated pure magnesium ingots, pure aluminum ingots, pure zinc particles, pure tin particles, pure a...

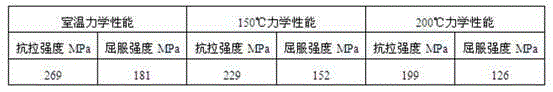

Embodiment 3

[0034] A low-cost multi-component heat-resistant magnesium alloy, the components and their weight percentages are: Al is 6.39%, Zn is 0.64%, Sr is 0.85%, Ca is 0.68%, Sn is 1.39%, Sb is 1.06%, Mn is 0.34%, Bi is 0.56%, Si is 0.76%, and the balance is Mg;

[0035] A method for preparing a heat-resistant magnesium alloy as described above, comprising the following steps:

[0036] 1) Weigh pure magnesium ingots, pure aluminum ingots, pure zinc particles, Mg-Sr master alloys, Mg-Ca master alloys, pure tin particles, pure antimony, Al-Mn master alloys, pure bismuth and Al- Si master alloy, spare;

[0037] 2) The pure magnesium ingot, pure aluminum ingot, pure zinc grain, Mg-Sr master alloy, Mg-Ca master alloy, pure tin grain, pure antimony, Al-Mn master alloy, pure bismuth and Al -Si master alloys were dried and preheated at 195°C for 4 hours, and set aside;

[0038] 3) Put the preheated pure magnesium ingots, pure aluminum ingots, pure zinc particles, pure tin particles, pure a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com