Pinwheel-shaped and tree root-shaped quarter section tangential water gap for continuous casting

A windmill-shaped nozzle technology, which is applied in casting equipment, casting molten material containers, metal processing equipment, etc., to achieve the effects of easy processing and production, lower production costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

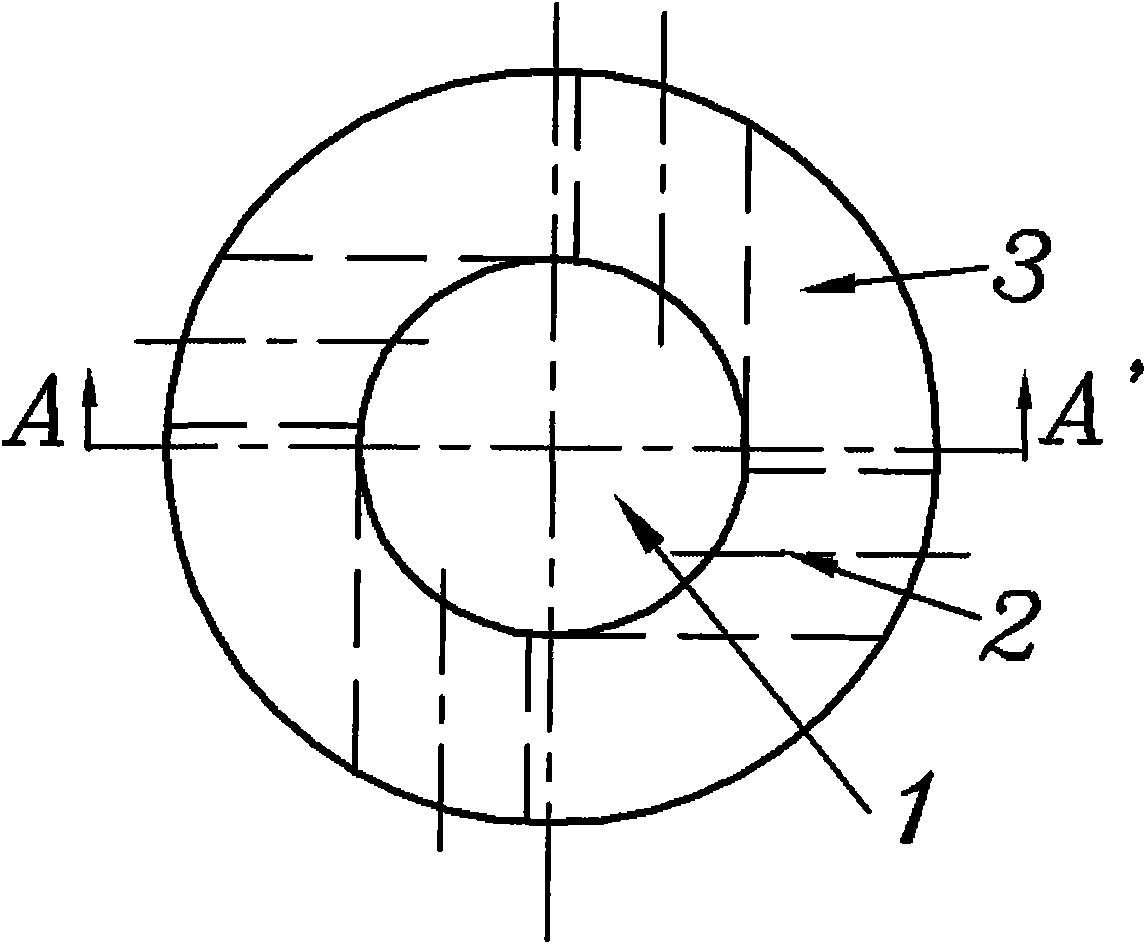

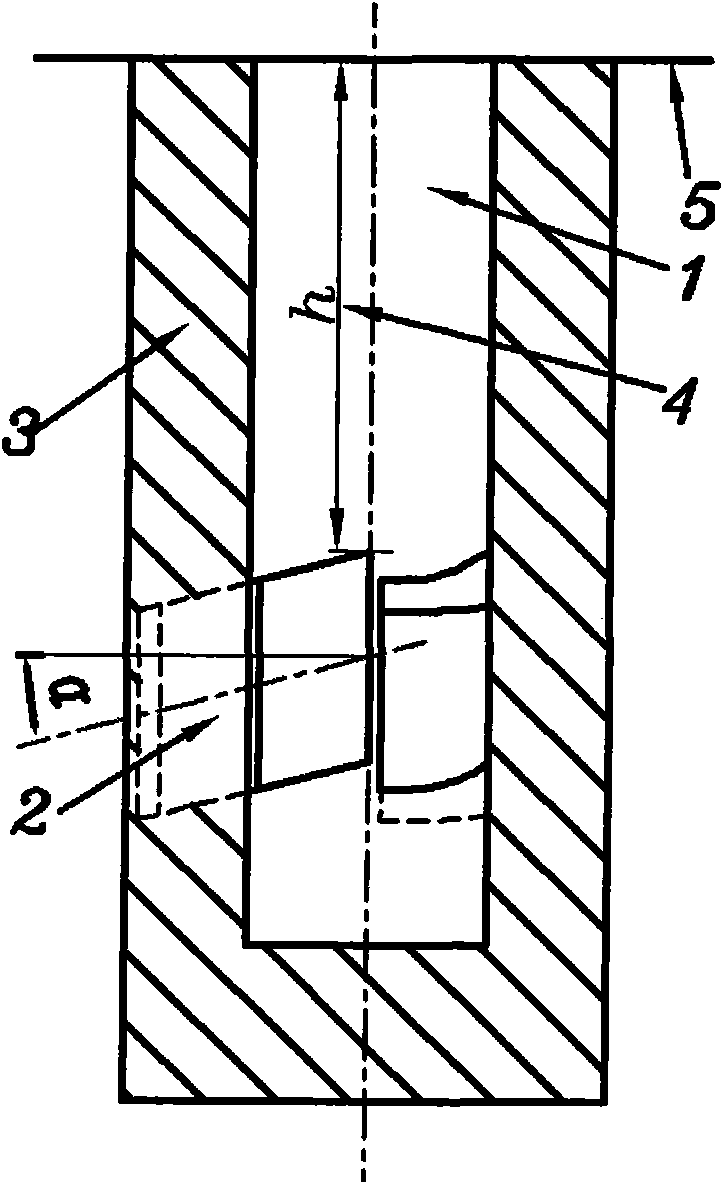

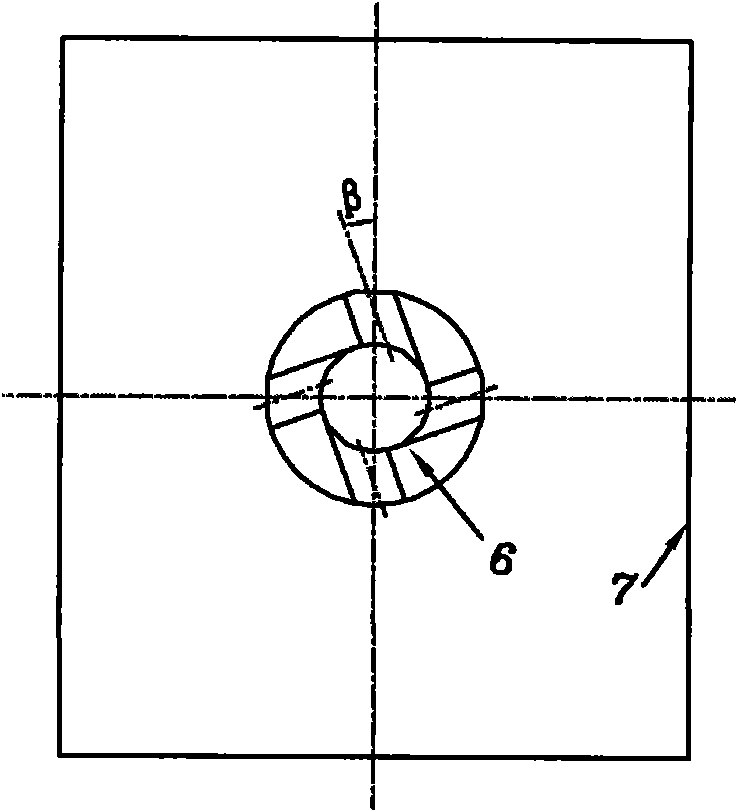

[0017] The present invention is made of anti-blocking refractory material (such as zirconium-calcium composite material, spinel, etc.), and can be made according to the existing submerged nozzle manufacturing technology, wherein the outer edge line of the nozzle side hole (2) needs to be consistent with the nozzle middle hole ( 1) Tangent, and the nozzle side hole (2) has a certain inclination angle α. When casting a rectangular slab with a section size of 260mm×300mm, the inclination angle α of the side hole of the quartered tangential nozzle (6) is 15°, the installation angle β is 20°, and the immersion depth h(4) can be 100mm. When casting a round billet with a cross-sectional size of φ400mm, the inclination angle α of the side hole of the quartered tangential nozzle (6) can be 15°, the installation angle β can be any value, and the immersion depth h (4) is 100mm. In addition, before casting, the quartered tangential nozzle (6) needs to be preheated for a certain period of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com