Production method of compressed compact carbonized wood

A wood and carbonization technology, which is applied in the direction of pressurized wood treatment, wood treatment, impregnated wood, etc., can solve the problems that the mechanical strength and waterproof dimensional stability of wood cannot be simultaneously improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

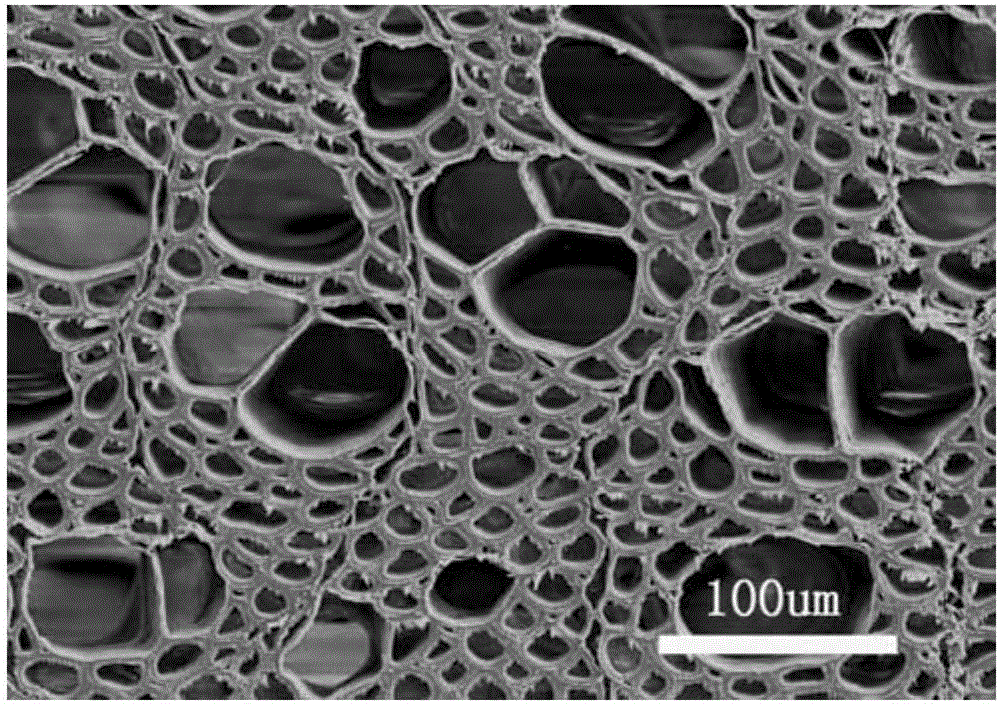

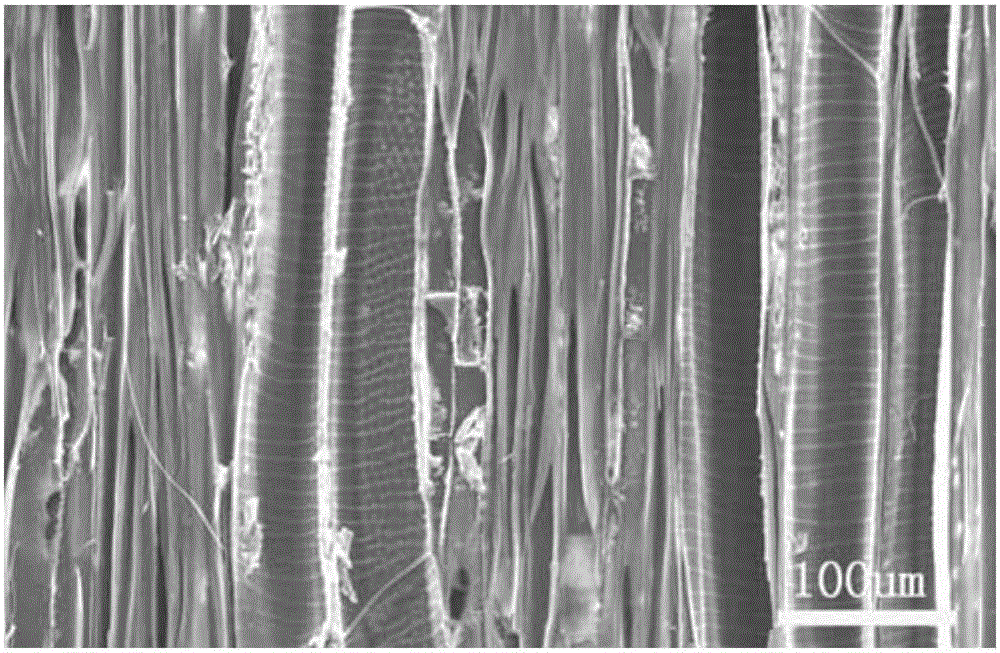

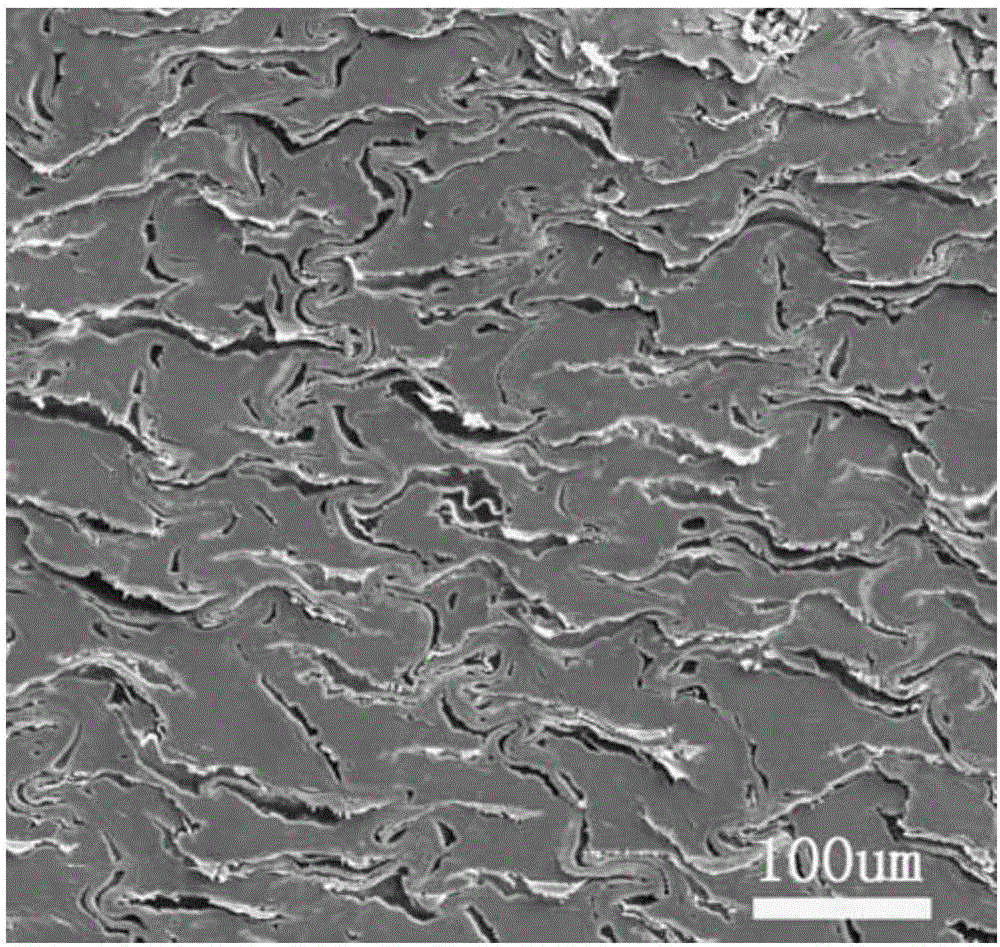

Image

Examples

specific Embodiment approach 1

[0035] Specific implementation mode one: the preparation method of compressed and compacted carbonized wood in this embodiment comprises the following steps:

[0036] 1. Wood softening pretreatment:

[0037] Expose the wood to NaOH and Na 2 SO 3 In the mixed aqueous solution, heat treatment at 80-90°C for 5-10h, and then wash the wood with distilled water at room temperature until it is neutral to obtain softened wood;

[0038] 2. Compression treatment of softened wood:

[0039] Put the softened wood in a hot press, compress the wood thickness to 20%-25% of the original under the pressure of 3-5MPa at room temperature, then raise the temperature step by step, first raise the temperature to 60-80°C and keep the pressure for 8-10h, Then continue to heat up to 100-120°C and keep the pressure for 24-48h;

[0040] 3. Wood high temperature carbonization treatment:

[0041] Put the treated wood in step 2 in a high-temperature carbonization box, raise the temperature to 130-150°C...

specific Embodiment approach 2

[0043] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mass concentration of NaOH in the mixed aqueous solution described in step 1 is 1%-5%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment differs from Embodiment 1 in that: the mass concentration of NaOH in the mixed aqueous solution described in step 1 is 2%-4%. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com