Preparation method of high-strength compact wood

A high-strength, wood technology, applied in wood compression, wood treatment, wood heating and other directions, can solve the problems of insufficient mechanical properties, time-consuming and energy-consuming processing and preparation, and high processing costs, achieving low preparation costs, small proportion of pores, The effect of improving the degree of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

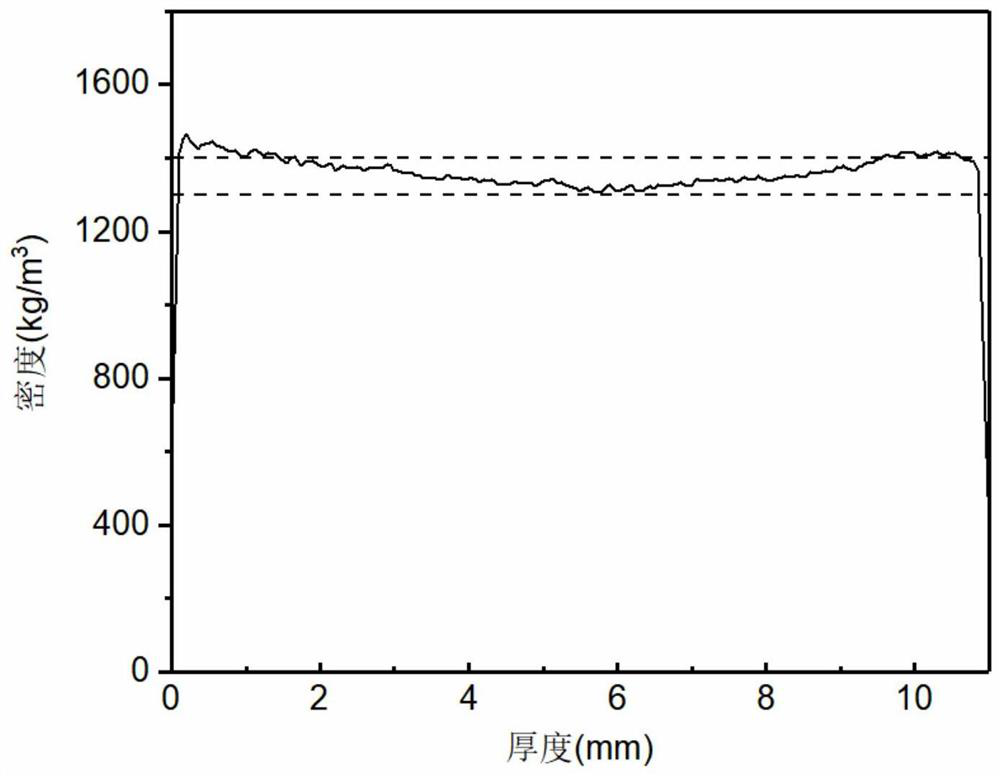

Image

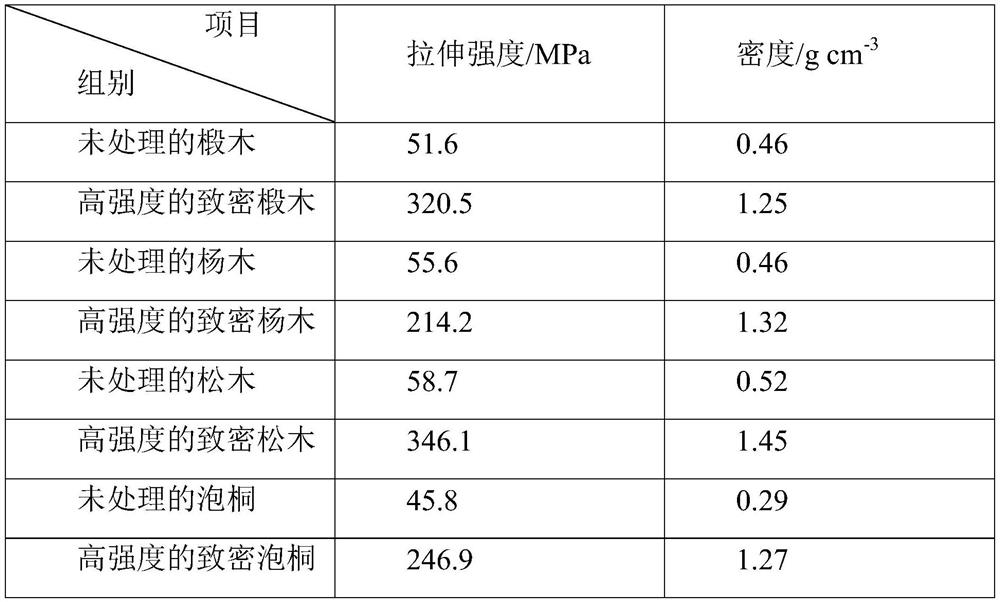

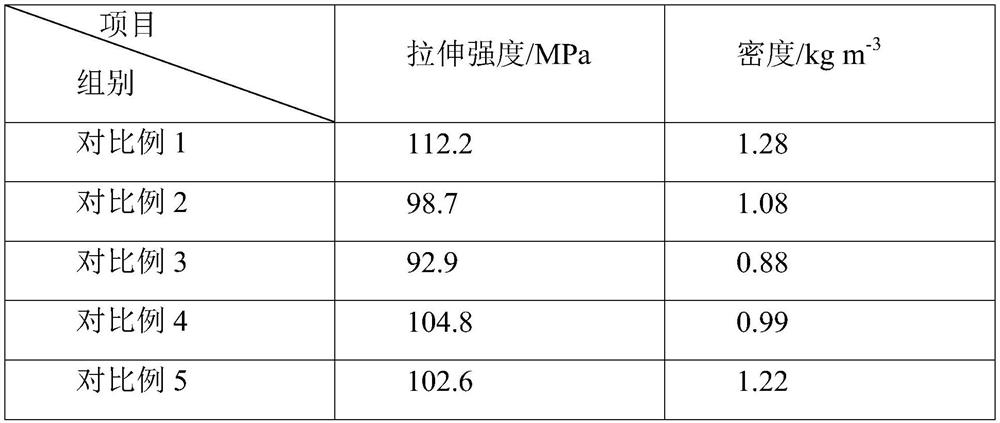

Examples

preparation example Construction

[0024]A method of preparing a high intensity dense wood in an embodiment of the present invention, comprising the steps of:

[0025]The wood raw material is placed in a vacuum pressurized tank, soaking under the basic treatment solution under vacuum conditions, the wood raw material is fully impregnated;

[0026]The alkaline treatment solution of the soaking wood is heated, and then removed after cooling;

[0027]Wood after heating treatment is cooked;

[0028]Drying treatment after the cooking treatment is dried to obtain a dry wood;

[0029]The dry wood is placed in a hot press to perform hot press processing, heat insulation treatment, and cooling treatment to obtain high-strength dense wood.

[0030]In one of the embodiments, the wood raw material is one or more of poplar, pine, eucalyptus, aquatic willow, and pair.

[0031]In one of the embodiments, the wood raw material has a size of 100 mm × 50 mm × 50 mm.

[0032]In one of the embodiments, the alkaline treatment solution is a mixed solution of sodi...

Embodiment 1

[0053]200 g of sodium hydroxide and 100 g sulfite were dissolved in deionized water, and the solution was 2000 ml, and the alkaline treatment solution was configured;

[0054]Eucalyptical sizes of 100 mm × 50 mm × 50 mm was placed in a vacuum pressurizing tank and soaked in the alkaline treatment solution, vacuuming to -0.9 MPa, maintained for 30 min;

[0055]The alkaline treatment solution of the soaked eucalyptus is then placed in 100 ° C for water bath heating treatment, and after 7 h, the cooling is removed;

[0056]The eucalyptus after heating of the water bath is placed in deionized water, heated to 100 ° C, replace it once every 1h, a co-cooking treatment for 8 h, and then removed after cooling;

[0057]The eucalyptus after the cooking treatment was placed at 20 ° C, the relative humidity was 85% constant temperature and humidity tank, and the aqueous content of the eucalyptus was 20%;

[0058]The dried eucalyptus is placed on a pressure plate of 100 ° C, and the pressure plate is closed, s...

Embodiment 2

[0060]200 g of sodium hydroxide and 100 g sulfite were dissolved in deionized water, and the solution was 2000 ml, and the alkaline treatment solution was configured;

[0061]Putting the specification size of 100 mm × 50 mm × 50 mm into a vacuum pressurizing tank and soaked in the alkaline treatment solution, vacuuming to -0.9 mPa, maintained for 30 min;

[0062]The alkaline treatment solution of the soaking poplar is placed in 100 ° C for water bath heating treatment, and after 7 h, the cooling is removed;

[0063]Yang is placed in a water bath to be placed in deionized water, heated to 100 ° C, replacement of deionized water at once every 1h, coastal treatment for 8 h, and obtains a base to give a base treatment poplar;

[0064]The moisture content of 200 ° C after the cooking treatment was placed at 20 ° C, and the relative humidity was 85%, and the water content was 20%;

[0065]The dried poplar is placed on a pressure plate of 100 ° C, and the pressure plate is closed, so that the upper plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overall density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com