Wicker pole peeling device

A wicker and peeling machine technology, applied in the field of wood processing, can solve problems such as unclean dialing, low efficiency, and inability to automatically load materials, and achieve the effects of increasing stability, overcoming slow efficiency, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0017] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

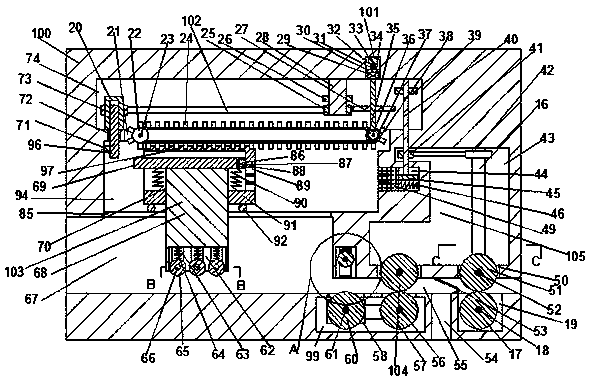

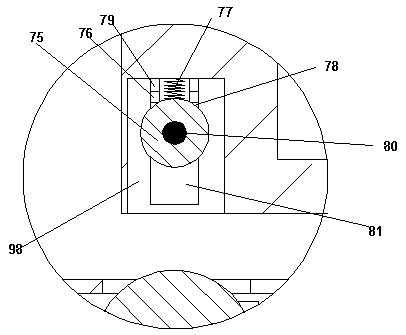

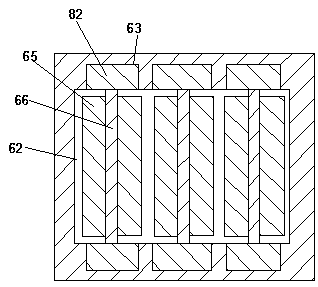

[0018] see Figure 1-4, an embodiment provided by the present invention: a device for peeling wicker rods, including a peeling machine 100, a motor chute 31 is provided in the peeling machine 100, a power device 101 is provided in the motor chute 31, the The lower end wall of the motor chute 31 is provided with an adjustment space 74, and the adjustment space 74 is provided with an adjustment device 102. The adjustment device 102 includes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com