Thin film with low friction coefficient and high water contact angle and preparation method thereof

A technology with low friction coefficient and contact angle, applied in the direction of primers, epoxy resin coatings, polyester coatings, etc., can solve the problems of smooth film and poor anti-fingerprint effect, not suitable for mass production, complicated preparation process, etc. Achieve the effects of low processing cost, overcome slippery and poor anti-fingerprint effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

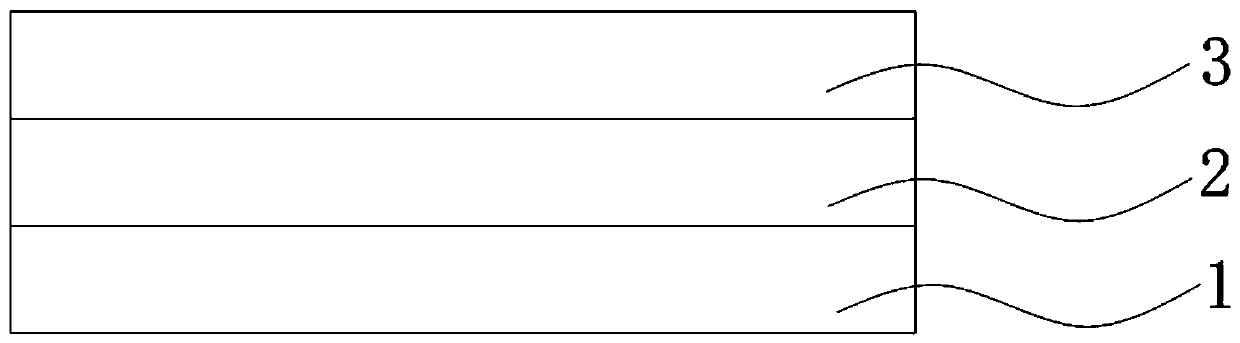

[0029] refer to figure 1 , this embodiment provides a film with a low coefficient of friction and a high water contact angle, including a transparent base film 1 , a primer layer 2 and an AF layer 3 laminated sequentially from bottom to top.

[0030] The material of the transparent base film 1 can be PET (polyterephthalic acid plastics), TAC (triacetate film), PC (polycarbonate), PE (polyethylene), PP (polypropylene), PI (polyamide imine), PMMA (polymethyl methacrylate), TPU (thermoplastic polyurethane elastomer) or PEN (polyethylene phthalate), the thickness of the transparent base film 1 is 20 μm to 500 μm, and the preferred thickness is 50 μm -200 μm. The AF layer 3 is a coating formed by curing the AF liquid; the main component of the AF liquid is a fluorine-containing compound, which can be purchased directly from the market; the coating thickness of the AF layer 3 is between 5nm and 100nm, and the preferred thickness is 10nm- 80nm.

[0031]The undercoat layer 2 is for...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that: in terms of mass percentage, the raw material composition of the primer liquid can also include 1% to 5% of additives, and the additives include nano-silica, silicon-containing additives, anti-corrosion One or a combination of static agents. In this embodiment, nano silicon dioxide is also added to the primer solution.

[0040] The difference between the method for preparing the above-mentioned film in this example and Example 1 is that in step S002, optional components are added when configuring the primer solution, and the optional components include nano-silicon dioxide, silicon-containing additives, and antistatic agents. one or a combination of several. In this embodiment, the additive component is nano silicon dioxide.

Embodiment 3

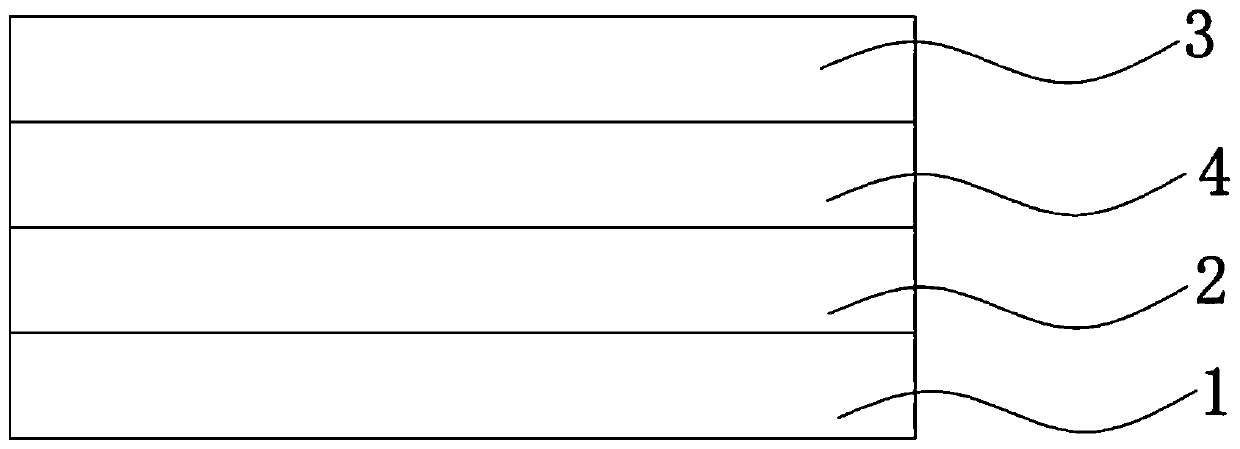

[0042] refer to Figure 2 to Figure 4 , the difference between this embodiment and embodiment 1 is: a stabilizing layer 4 is bonded between the primer layer 2 and the AF layer 3, and the stabilizing layer 4 is formed by curing a silane solution, and the coating thickness of the stabilizing layer 4 is 5nm~150nm , the preferred thickness is 10nm-100nm. In terms of mass percentage, the raw material composition of the silane solution includes: silane coupling agent 0.1% to 2% and solvent, the silane coupling agent includes γ-aminopropyltriethoxysilane, γ-glycidyl etheroxypropyl Trimethoxysilane, γ-(methacryloyloxy)propyltrimethoxysilane, N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, γ-glycidyl ether One or more combinations of oxypropylmethyldiethoxysilane, vinyltriethoxysilane, vinyltrimethoxysilane, vinyltris(β-methoxyethoxy)silane, The solvent includes one or more mixtures of ethanol, methanol, isopropanol and acetone.

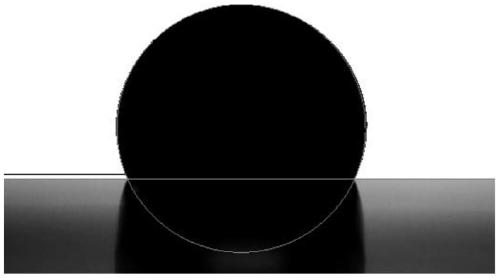

[0043] refer to Figure 5 The difference betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com