Pressing plate vacuum chamber

A technology of vacuum chamber and pressure plate, which is applied in the direction of forming pressure head, etc., can solve the problems of complex structure of vibration motor heat dissipation system, increase of equipment weight and manufacturing cost, and difficult maintenance of internal components, so as to simplify the structure, overcome high manufacturing cost and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

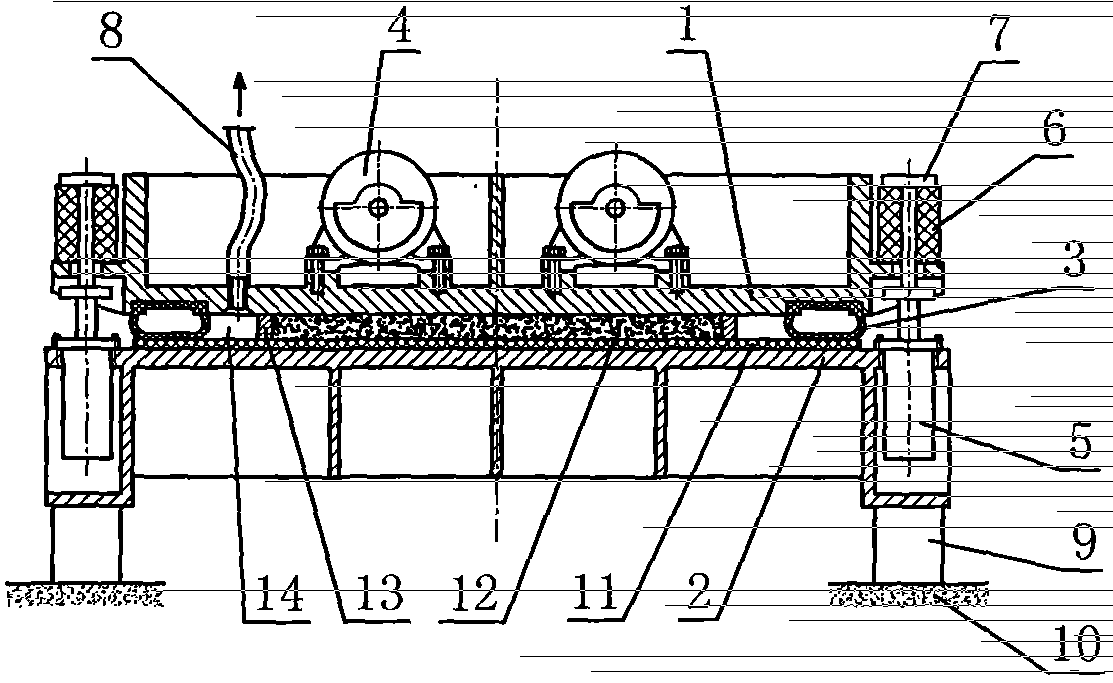

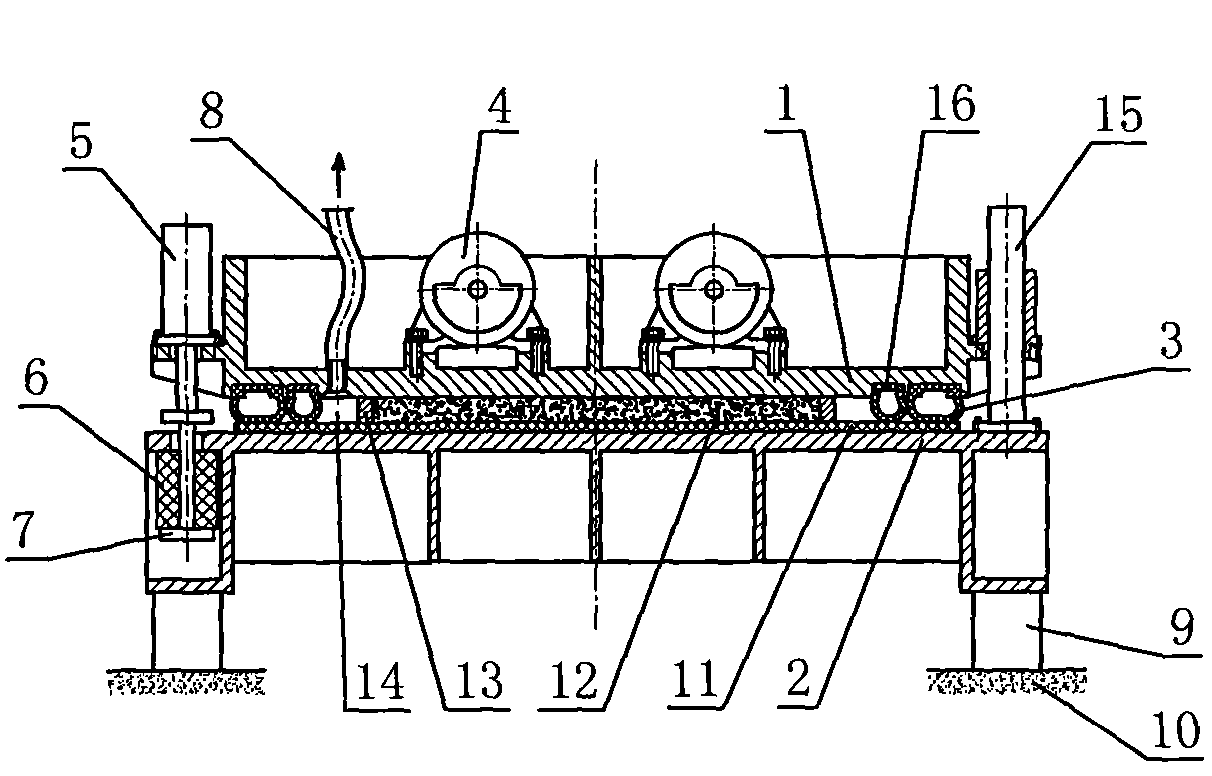

[0022] The specific implementation of the platen vacuum chamber of the present invention will be further described below in conjunction with the accompanying drawings:

[0023] figure 1 As shown: the embodiment of the pressure plate vacuum chamber of the present invention, the inflatable sealing ring 3 is arranged between the pressure head 1 and the base 2, and is fixed on the lower periphery of the pressure head 1. When working, the conveying belt 11 transports the blank 12 to the bottom of the pressure head 1, the lifting cylinder 5 moves to lower the pressure head 1, and the inflatable sealing ring 3 is lowered accordingly, and the blank 12 and the mold 13 are covered on the base 2, and the air is sealed. An airtight cavity 14 is formed between the inside of the ring 3 and the pressure head 1 and the base 2, and the airtight cavity 14 is evacuated through the vacuum tube 8 connected to the airtight cavity 14, and the lifting cylinder 5 fixed on the base 2 is connected to it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com