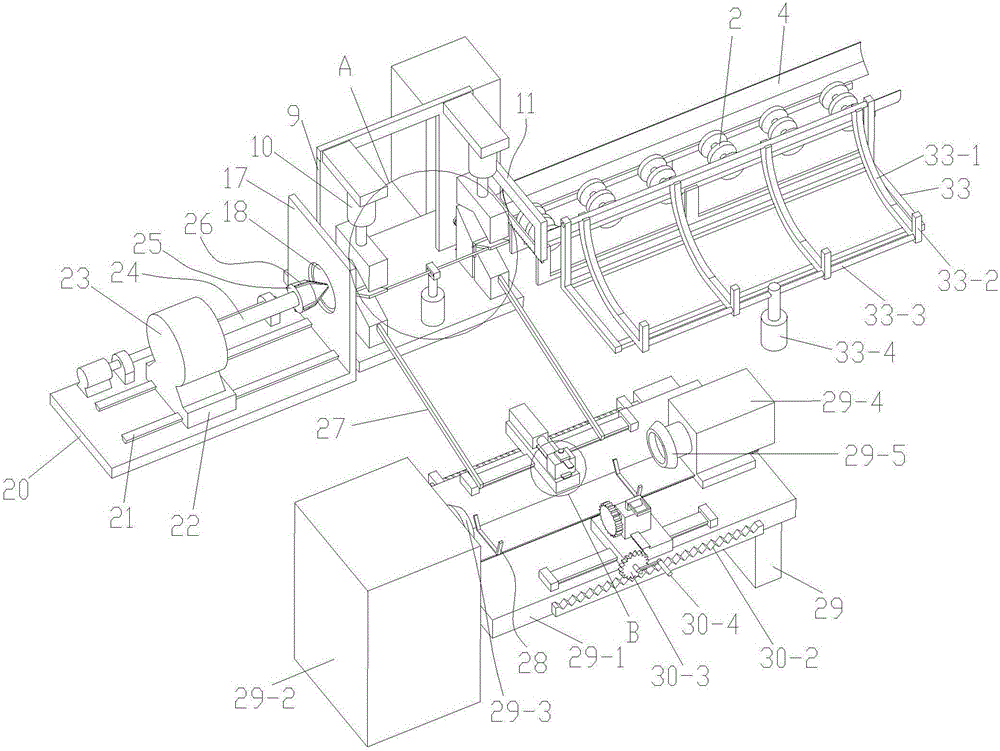

Full-automatic bamboo tube machining production line

A fully automatic, production line technology, applied in wood processing equipment, sugarcane machining, manufacturing tools, etc., can solve problems such as low work efficiency, product quality impact, difficult to remove bamboo green, etc., and achieve high cutting surface precision and reasonable structural design , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

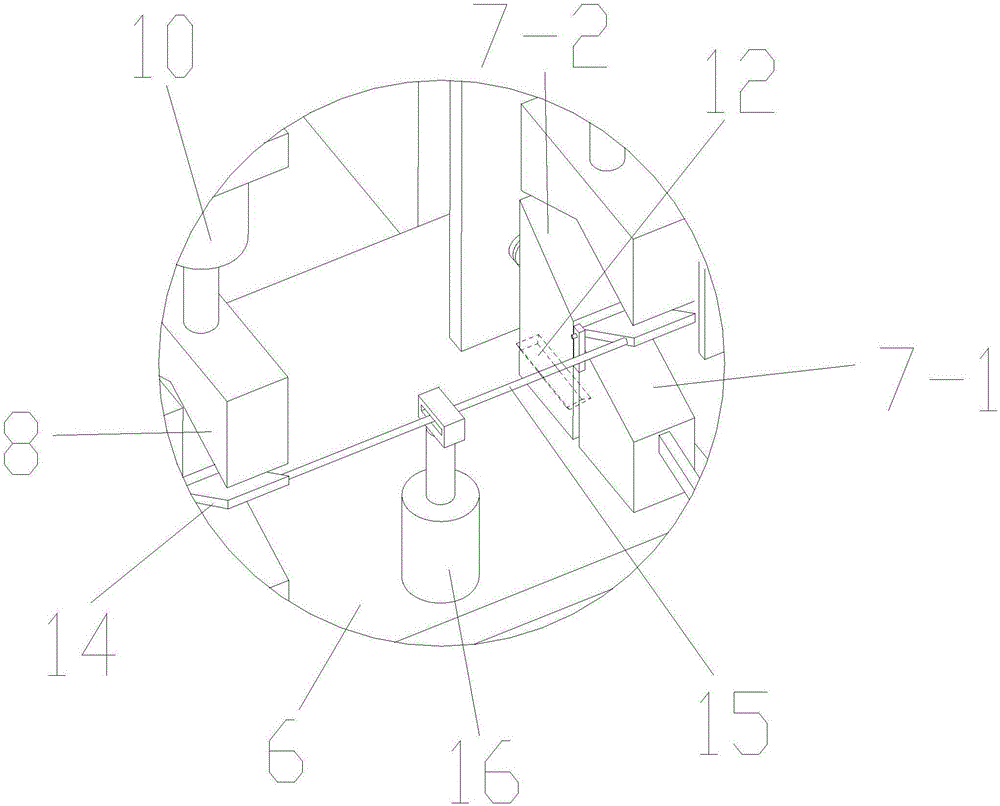

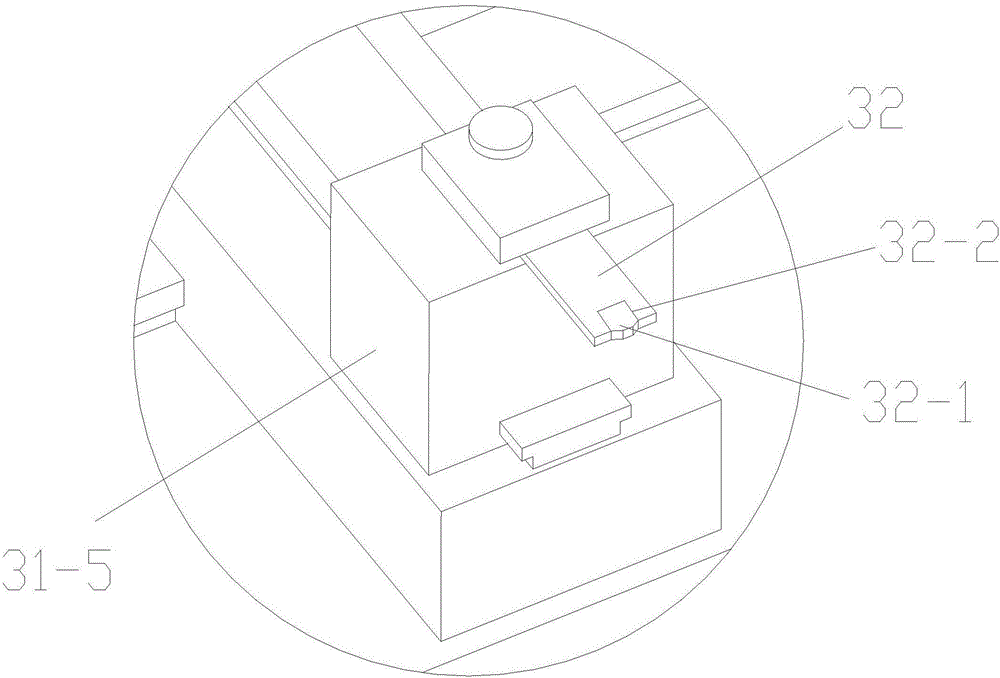

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] Referring to the accompanying drawings: the bamboo tube automatic processing production line in the present embodiment comprises a conveying frame 1, a row of conveying wheels 2 is installed on the conveying frame 1, the conveying wheels 2 are connected with a conveying motor 3, and the front and rear sides of the conveying frame 1 are respectively equipped with inclined Side baffle plate 4, rack 33 is installed on the front side of conveying frame 1, and a group of storage rod 33-1 is installed on the storage rack 33, and the rear end of storage rod 33-1 is positioned at the top of side baffle plate 4 and is connected in rotation On the object rack 33, the front end of the object rod 33-1 is equipped with a stop bar 33-2, and the front end of the object rod 33-1 is connected by a fixed rod 33-3, and the fixed rod 33-3 is installed on the support cylinder 33-4.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com