Automatic-feed-type reed peeling machine

A technology of peeling machine and feeding machine, which is applied in the direction of peeling wicker poles, conveyors, mechanical equipment, etc., can solve the problems of uneven wear of steel brushes of peeling machines, reduced service life, and harmful health of operators Uniform wear, improve work efficiency, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

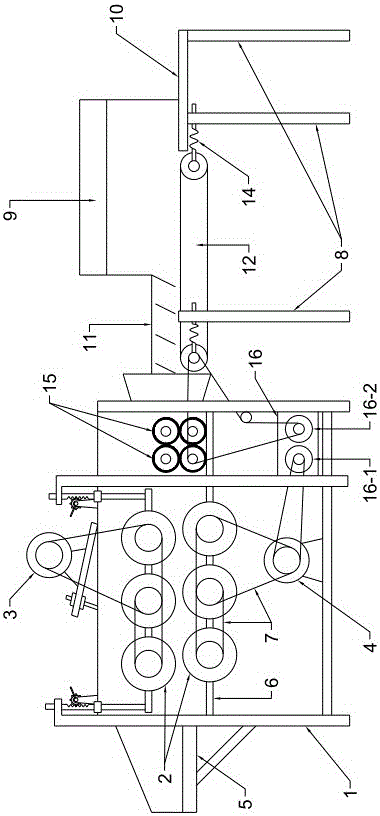

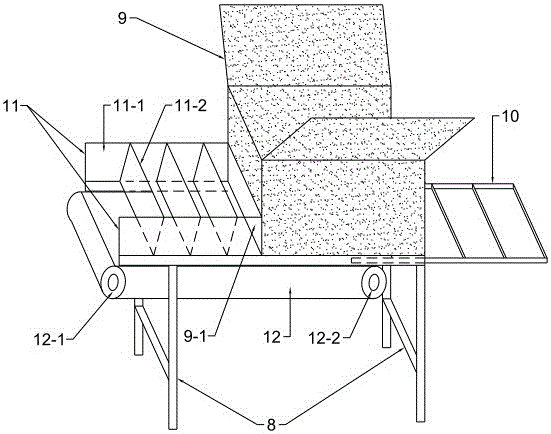

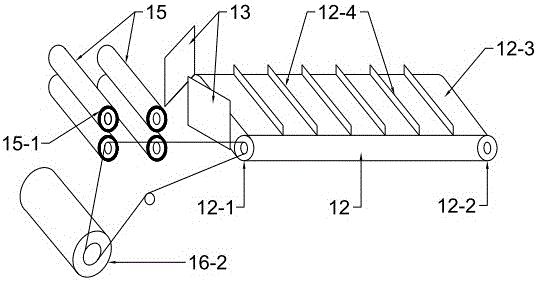

[0034] Attached below figure 1 ~ attached Figure 5 The present invention is described in detail below.

[0035] Such as Figure 1 to Figure 5 As shown, the present invention includes a peeling mechanism and an automatic feeding mechanism. The automatic feeding mechanism and the peeling mechanism are combined to form a running channel in which reed materials enter from one end and output from the other end after being peeled.

[0036] The peeling mechanism includes a peeling frame 1, a plurality of steel wire cylinders 2, a first motor 3, a second motor 4, a roller spacing adjustment device and a discharge unit 5; the peeling mechanism adopts a traditional steel wire cylinder peeling structure, and in this technical solution Set up two asynchronous motors.

[0037] Described peeling frame 1 is frame structure frame, and peeling frame 1 inner side upper part is provided with two channel steels 6 up and down, the channel steel 6 two ends of upper end are separated with peelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com