Mechanical arm

A mechanical arm and clamping arm technology, applied in the field of mechanical automation, can solve the problems of excessively loose clamping of overloaded items, manual adjustment, handling damage, etc., to achieve the effects of easy clamping, smooth feeding, and prevention of detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

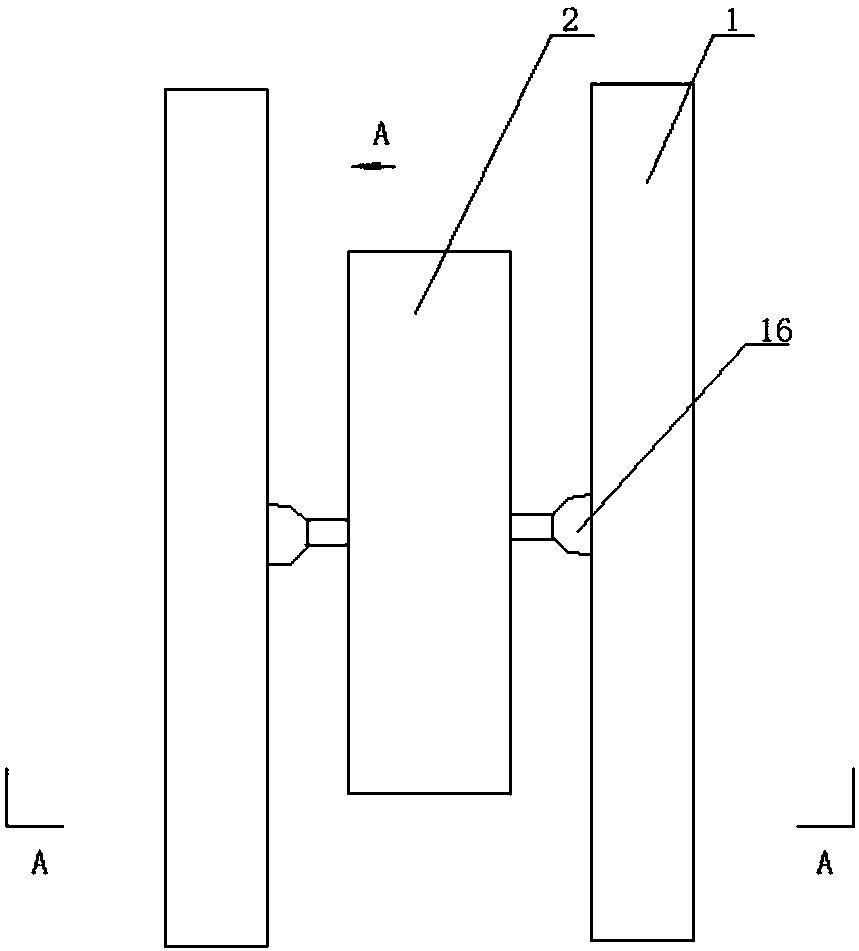

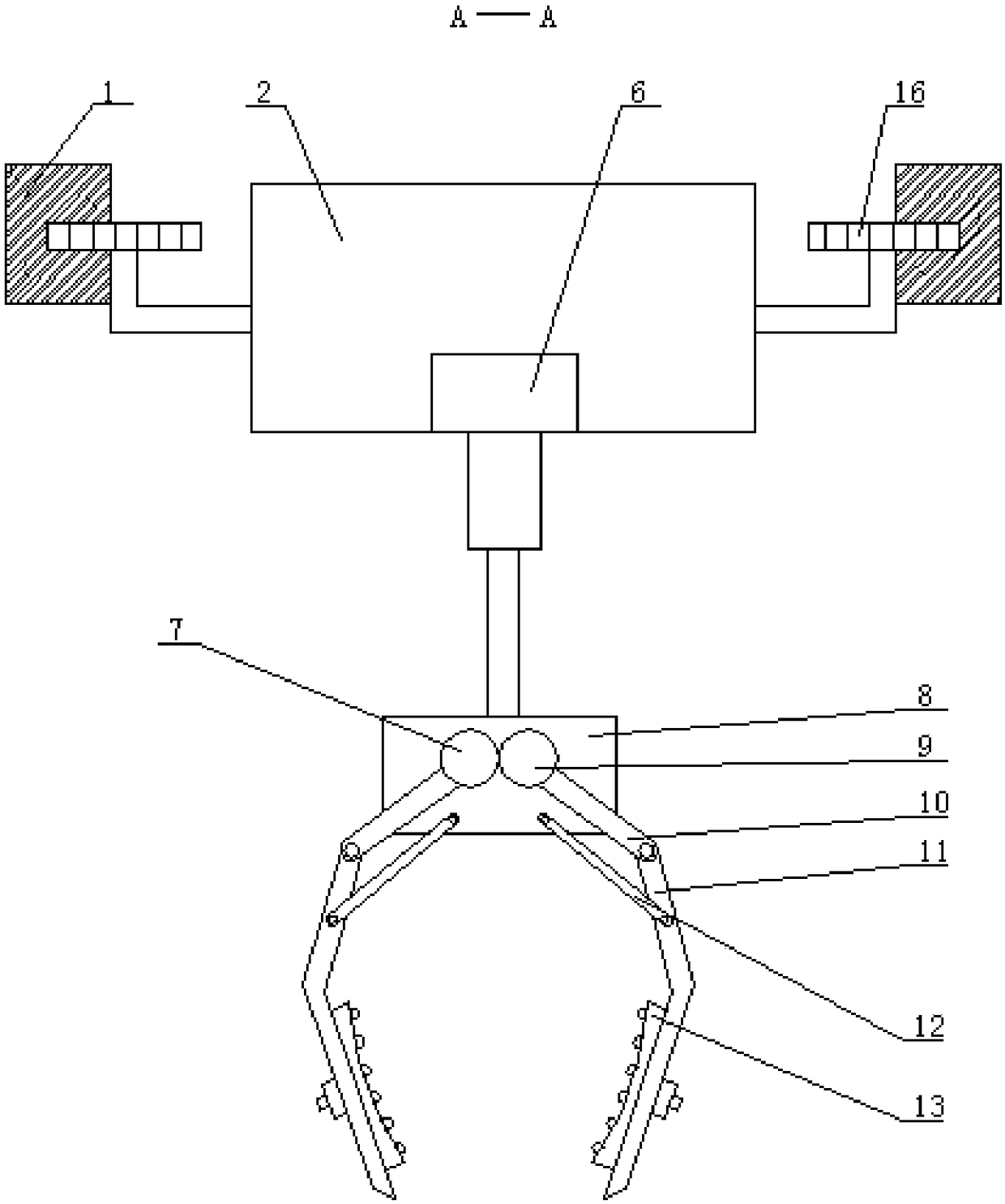

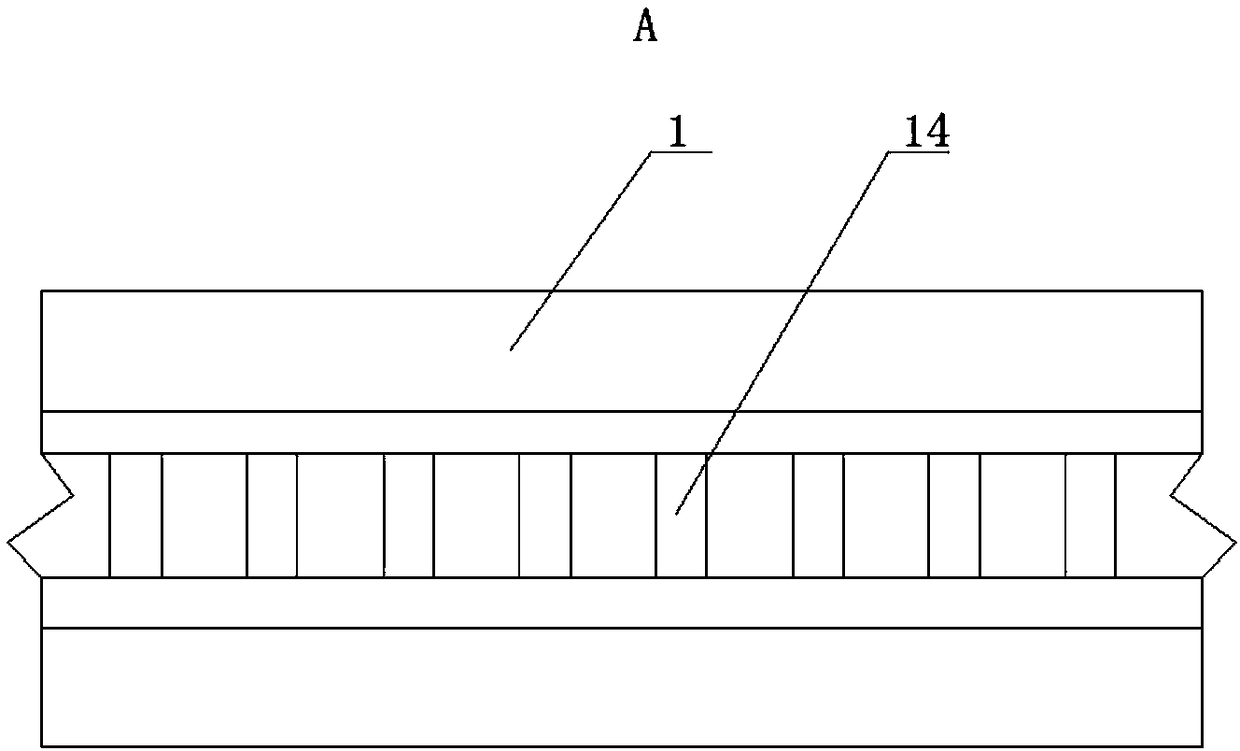

[0020] A mechanical arm of the present invention includes a horizontal motion mechanism, a horizontal motion body 2, a vertical motion mechanism, a vertical motion body 8, a clamping drive mechanism, and a clamping arm 11; the horizontal motion mechanism includes two parallel and horizontally placed guide rails 1. Horizontal drive mechanism; the vertical movement mechanism includes the first telescopic cylinder 6;

[0021] The horizontal movement mechanism moves along the two guide rails 1 through the horizontal drive mechanism to realize the horizontal movement of the horizontal movement body 2, and realizes the smooth movement of the horizontal movement body through the restriction of the two symmetrical guide rails 1; the first telescopic cylinder 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com