Tailing slurry collection buffering feeding device and method

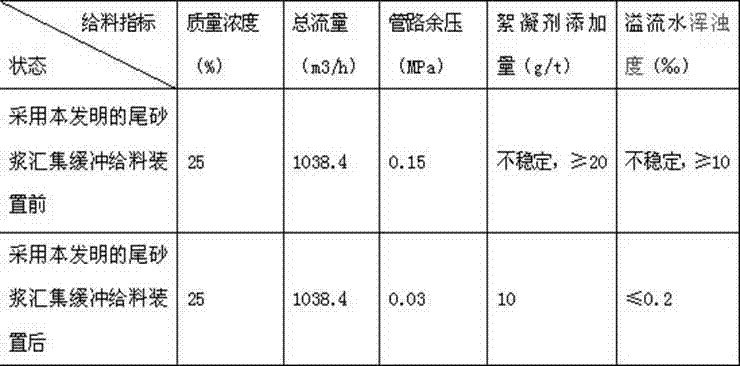

A feeding device and tailings technology, applied in safety devices, earth square drilling, filling, etc., can solve the problem of affecting the concentration of tailings and the overflow water quality of storage facilities, disturbing the settlement and concentration of tailings, and increasing the flocculant Adding amount and other issues to achieve the effect of improving overflow water quality, saving operating costs, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

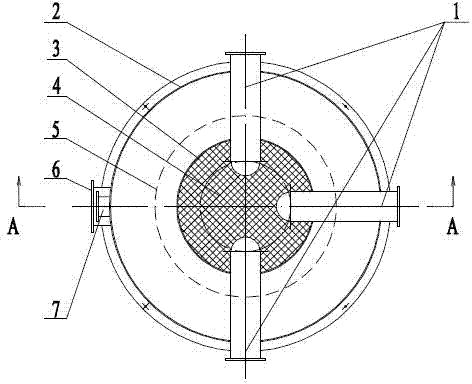

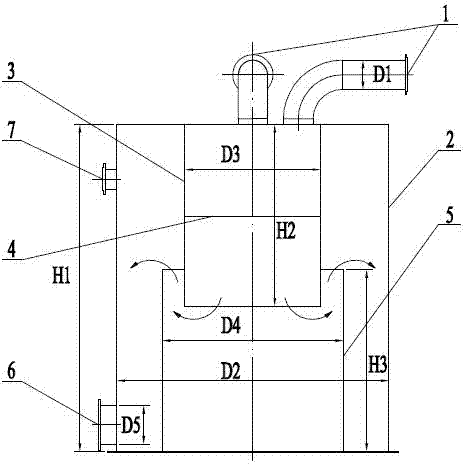

[0020] As shown in the figure, the tailing mortar collection buffer feeding device includes a box body 2 with a top plate and a base, a diversion collection barrel 3 fixed below the top plate of the box body 2 and extending downward along the height direction of the box body, a fixed The mixing overflow buffer barrel 5 extending upward along the height direction of the box body above the base of the box body 2, the feed pipe 1 communicating with the inner cavity of the diversion collection barrel 3, and the discharge pipe arranged at the lower part of the side wall of the box body 2 6 and the grid sieve 4 located in the diversion collection bucket 3. The upper edge of the mixing overflow buffer bucket 5 is not lower than the lower edge of the diversion and collection bucket 3 , preferably, the upper edge of the mixing overflow buffer bucket 5 is higher than the lower edge of the diversion and collection bucket 3 . The diameter of the mixed overflow buffer barrel 5 is larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com