Preparation method of zinc oxide nanowire/carbon clothfriction material

A zinc oxide nanowire and friction material technology, applied in the field of friction materials, can solve problems such as weak interface bonding, and achieve the effects of small fiber strength damage, simple equipment and controllable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

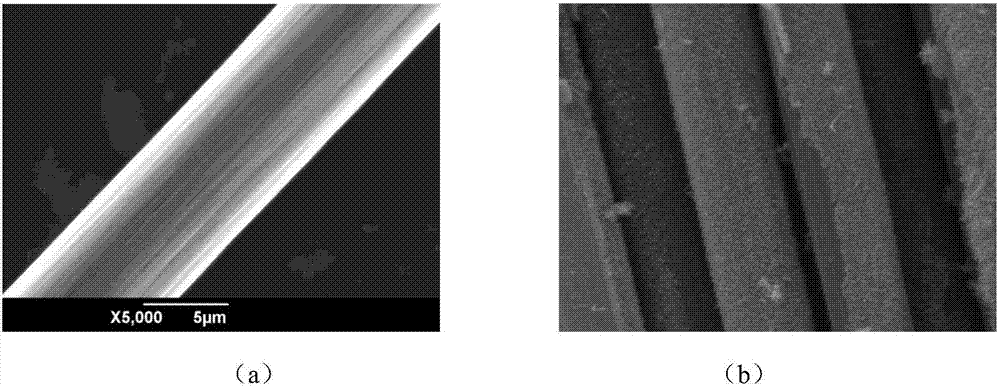

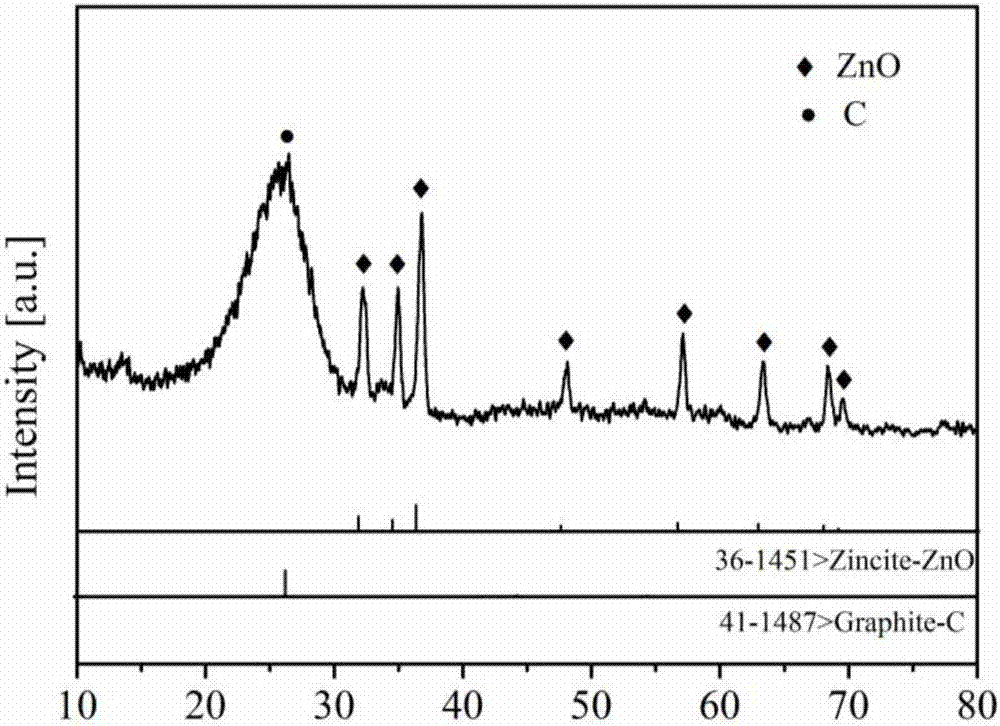

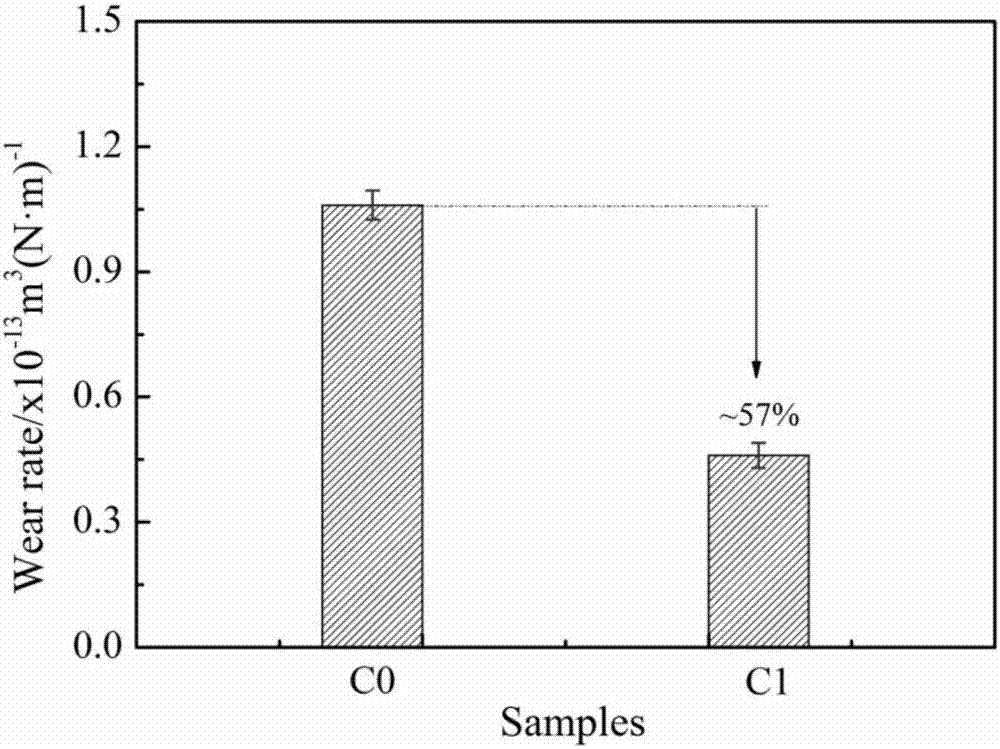

[0033] The invention provides a kind of preparation method of zinc oxide nanowire / carbon cloth friction material, at first adopt acetone, hydrogen peroxide (H 2 o 2 ) and so on to soak the carbon cloth, the former removes the organic impurities on the surface of the carbon cloth, increases the oxygen-containing functional groups on the surface of the carbon cloth, and then inoculates a layer of zinc oxide seed crystal layer on the surface of the carbon cloth, and then uses the hydrothermal method in a certain growth environment. Zinc oxide nanowires are evenly grown on the surface of the carbon cloth, and the treated carbon cloth is soaked in a modified phenolic resin solution, taken out and air-dried naturally, and hot-pressed with a vulcanizer to obtain the friction material. In the present invention, hydrogen peroxide or formic acid carbon cloth is used to increase the oxygen-containing functional groups on the surface of the carbon cloth, and impregnating the seed layer is...

Embodiment 1

[0045] Step 1: Soak a 5cm*8cm carbon cloth in acetone for 24 hours, then wash it with absolute ethanol and deionized water for 3 times, and then dry it to obtain sample A.

[0046] Step 2: Soak the carbon cloth in analytically pure hydrogen peroxide for 12 hours. Sample B was washed 3 times with deionized water and dried in an oven at 70 °C.

[0047] Step 3: Configuration of zinc source seed layer sol. Dissolve 1mmol of zinc acetate dihydrate and 2mmol of sodium hydroxide in 80ml and 100ml of absolute ethanol respectively, stir at 60°C and 500r / min to obtain solutions B and C, then cool solutions B and C to room temperature, and take from solution B Add 40ml of the solution to 320ml of absolute ethanol to obtain solution D, take 40ml from solution C and add it to 100ml of absolute ethanol to obtain solution E, slowly add solution E to solution D at 65°C, and stir at 500r / min for 10min Mix evenly and let stand for 24h to obtain Sol F.

[0048] Step 4: Sample B impregnated th...

Embodiment 2

[0054] Step 1: Soak a 5cm*8cm carbon cloth in acetone for 24 hours, then wash it with absolute ethanol and deionized water for 3 times, and then dry it to obtain sample A.

[0055] Step 2: Soak the carbon cloth in analytically pure hydrogen peroxide for 12 hours. Sample B was washed 3 times with deionized water and dried in an oven at 70 °C.

[0056] Step 3: Configuration of zinc source seed layer sol. Dissolve 1mmol of zinc acetate dihydrate and 2mmol of sodium hydroxide in 80ml and 100ml of absolute ethanol respectively, stir at 60°C and 500r / min to obtain solutions B and C, then cool solutions B and C to room temperature, and take from solution B Add 40ml of the solution to 320ml of absolute ethanol to obtain solution D, take 40ml from solution C and add it to 100ml of absolute ethanol to obtain solution E, slowly add solution E to solution D at 65°C, and stir at 500r / min for 10min Mix evenly and let stand for 24h to obtain Sol F.

[0057] Step 4: Sample B impregnated th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com