Bearing seal of single-sealing ring cone bit

A technology of roller cone bit and bearing sealing, applied in construction and other directions, can solve the problems of reducing the effective contact area of the claw bearing, damage to the strength of the roller cone, processing difficulties, etc., to improve the effective contact height and area, small strength damage, and sealing. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment describe in detail:

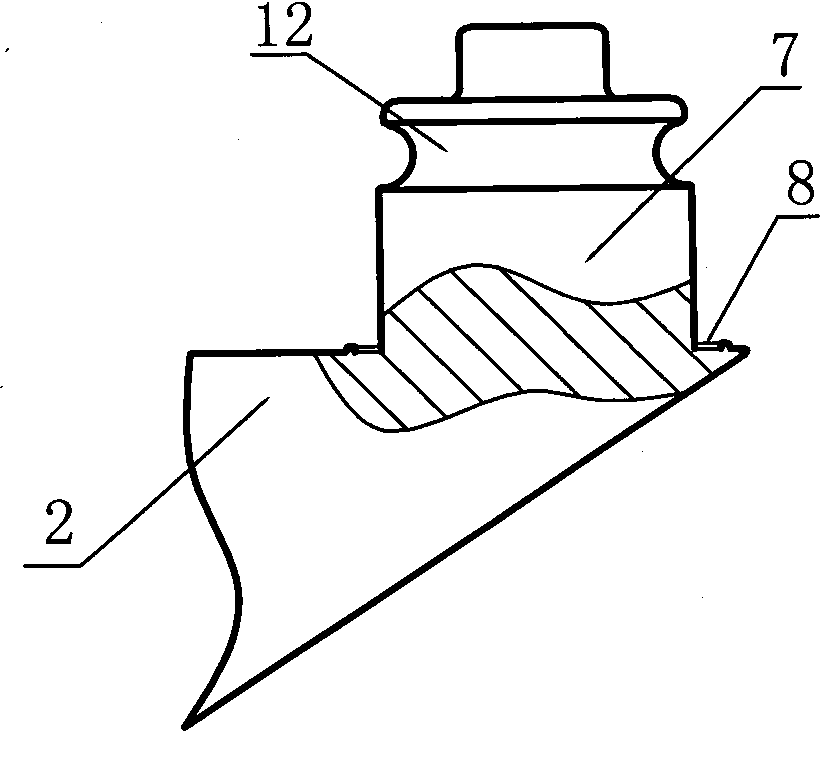

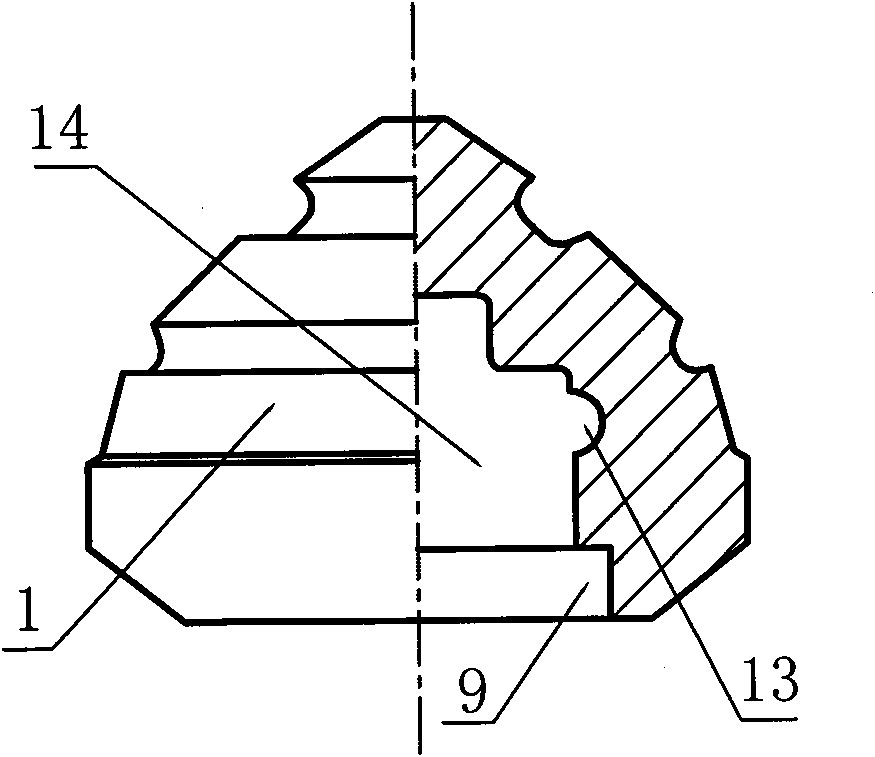

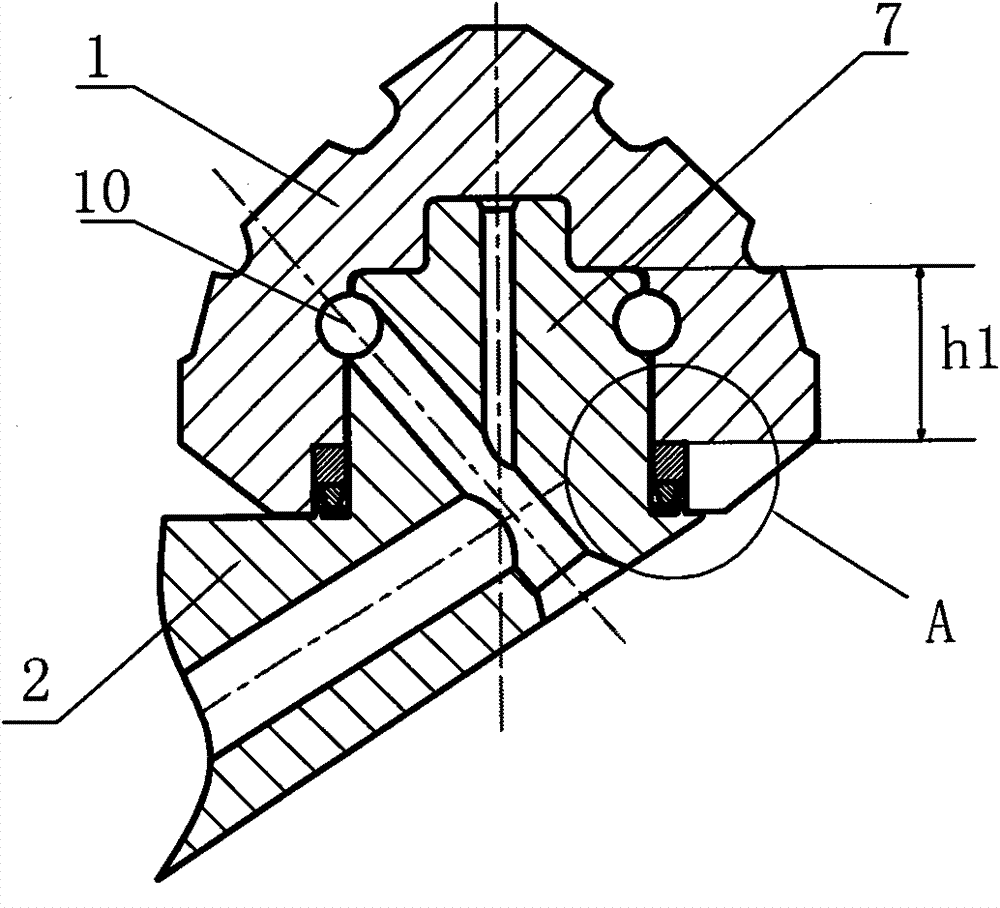

[0015] Such as figure 1 , 2 , 5 and 6, the bearing seal of the single sealing ring roller cone bit of the present invention includes a cone 1, claws 2, axial sealing ring 3 and radial sealing ring 4, and the claw 2 is provided with a claw shaft 7, The inner cavity 14 of the toothed wheel is set on the tooth claw shaft 7 and is suitable for each other. Steel balls 10 are arranged between the toothed wheel 1 and the toothed claw shaft 7. The steel ball 10 forms a bearing combination. At the same time, the steel ball 10 can rotate around the claw shaft 7 and keep the cone 1 relative to the claw shaft 7 in the axial direction fixed. The root of the claw shaft 7 is turned out of the annular groove 8, and the bottom of the toothed wheel cavity 14 is turned out of the annular gap 9. The static sealing body 6 is formed in the annular groove 8 by surfacing alloy materials. The surfacing elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com