In-situ non-ironing method for finishing cotton fabric through acrylic acid series of finishing agents

A technology for cotton fabrics and finishing agents, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve problems such as fabric strength damage and achieve good non-iron effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

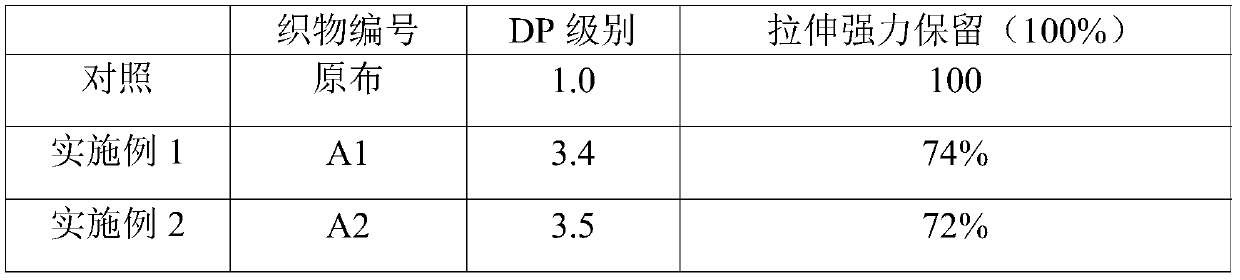

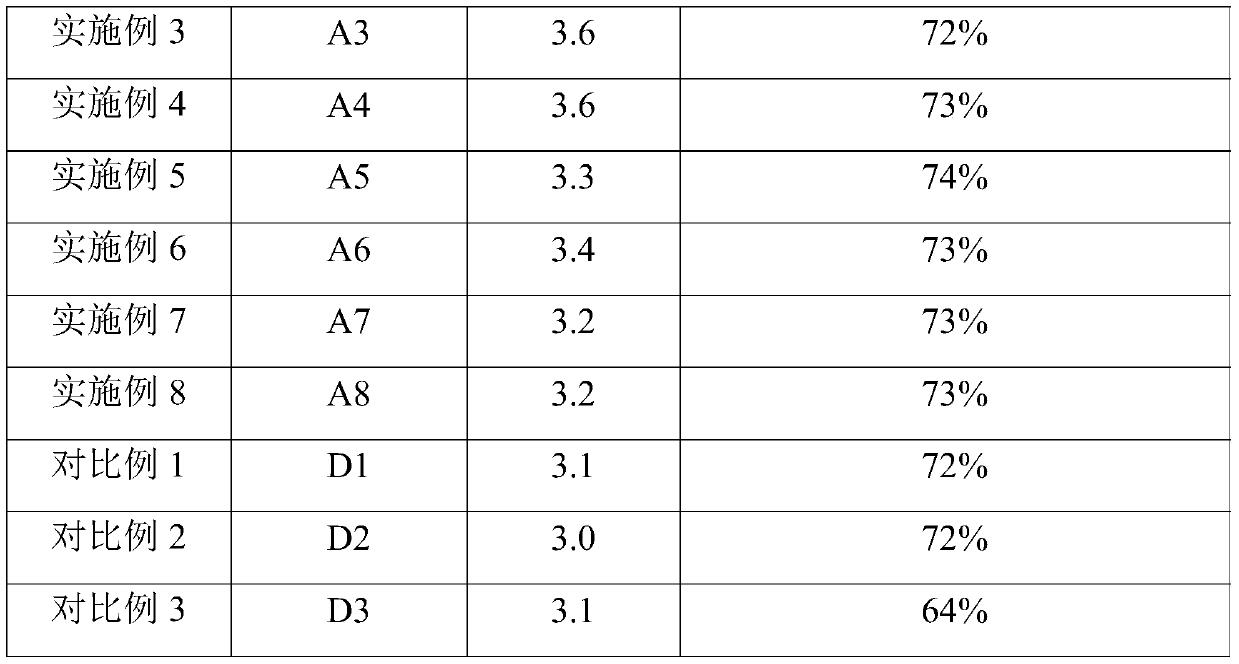

Examples

Embodiment 1

[0042] Add 11 parts by weight of ethanol to 100 parts by weight of water, add cotton fabric (the mass ratio of cotton fabric to water is 1:6), and stir at 50° C. for 20 minutes. Add 13 parts by weight of a mixture of dimethylaminoethyl methacrylate, hydroxyethyl methacrylate and methyl methacrylate (the mass ratio of the three is 1:1:1), and stir at 50° C. for 30 minutes. Next, under ultrasonic stirring, 3 parts by weight of maleic acid salt and 3 parts by weight of ammonium persulfate were sequentially added, the temperature was raised to 90° C., and the reaction was kept for 30 minutes. Then the above-mentioned treated cotton fabric is taken out, washed with water, and dried in the air, so as to obtain the non-ironing cotton fabric A1.

Embodiment 2

[0044] Add 10 parts by weight of ethanol to 100 parts by weight of water, add cotton fabric (the mass ratio of cotton fabric to water is 1:5), and stir at 40° C. for 30 minutes. Add 10 parts by weight of a mixture of dimethylaminoethyl methacrylate, hydroxyethyl methacrylate and methyl methacrylate (the mass ratio of the three is 1:0.8:1.2), and stir at 40° C. for 60 minutes. Next, under ultrasonic stirring, 2 parts by weight of fumarate and 4 parts by weight of ammonium persulfate were sequentially added, the temperature was raised to 80° C., and the reaction was maintained for 60 minutes. Then the above-mentioned treated cotton fabric was taken out, washed with water, and dried to obtain the non-ironing cotton fabric A2.

Embodiment 3

[0046] Add 12 parts by weight of ethanol to 100 parts by weight of water, add cotton fabric (the mass ratio of cotton fabric to water is 1:7), and stir at 60° C. for 10 minutes. Add 15 parts by weight of a mixture of dimethylaminoethyl methacrylate, hydroxyethyl methacrylate and methyl methacrylate (the mass ratio of the three is 1:1.2:0.8), and stir at 60° C. for 20 minutes. Next, under ultrasonic stirring, 4 parts by weight of itaconate and 2 parts by weight of ammonium persulfate were sequentially added, the temperature was raised to 100° C., and the reaction was kept for 20 minutes. Then the above-mentioned treated cotton fabric is taken out, washed with water, and dried in the air, thereby obtaining the non-ironing cotton fabric A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com