Preparing method for anti-wrinkle flax fabric and method for preparing flax anti-wrinkle textile

A fabric and linen technology, which is applied in the preparation of linen anti-wrinkle fabrics and anti-wrinkle linen fabrics, can solve the problems of unstable shrinkage, high crystallization area, and easy to wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

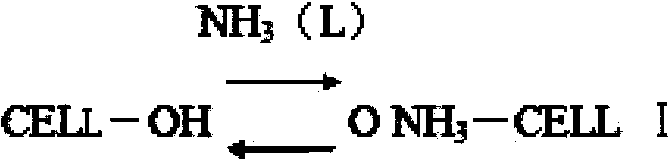

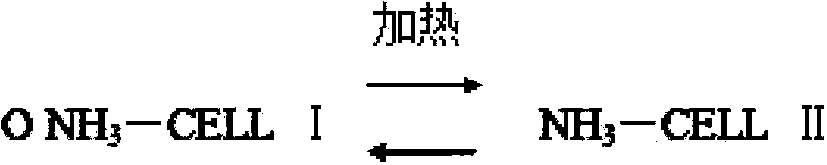

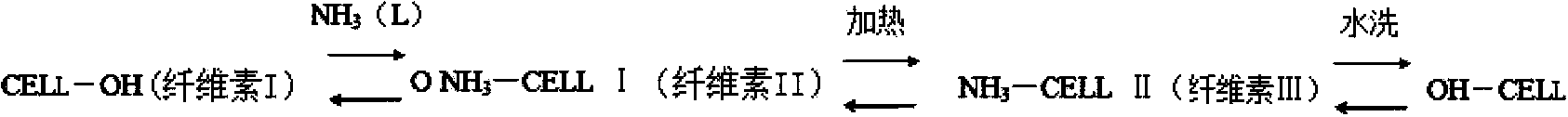

[0027] Embodiment 1: adopt liquid ammonia to process linen fabric, adopt following treatment process to process linen fabric:

[0028]

[0029] The treatment process is: air in the front row of liquid ammonia processing - ammonia filling - pressurization - fabric impregnated with ammonia gas reaction - heating reaction - ammonia gas recovery - fabric washing to remove ammonia.

[0030] Specifically, each process is:

[0031] Air in front of liquid ammonia processing: fill the air storage tank with nitrogen, and discharge the air out of the tank to prevent explosion due to the presence of air after filling ammonia;

[0032] Ammonia filling: After the air is discharged, fill the tank with ammonia;

[0033] Pressurization: make ammonia gas in gaseous state into liquid ammonia gas;

[0034] Fabric impregnated ammonia gas reaction: ammonia gas is input from the tank to the liquid ammonia production and processing equipment to react with the linen fabric, and the reaction press...

Embodiment 2

[0038] Embodiment 2: Preparation of linen wrinkle-resistant fabric

[0039] According to different technological routes, the following two processes can be used to prepare linen wrinkle-resistant fabrics:

[0040] (1) Linen gray cloth - pre-treatment bleaching - mercerizing - liquid ammonia - dyeing - non-ironing finishing (dry crosslinking) - baking - tentering - preshrinking - finished product;

[0041] (2) Linen gray cloth - pre-treatment bleaching - mercerizing - liquid ammonia - dyeing - moisture crosslinking - stacking - washing - tentering - preshrinking - finished product.

[0042] Wherein, each step technological parameter is as follows:

[0043] Pre-treatment bleaching, including scouring-acid washing-chlorine bleaching-oxygen bleaching-water washing, wherein the time and temperature of each step can be adjusted according to actual needs, the following is the preferred

[0044] Scouring: use NaOH 20-50g / l, preferably at 95-100°C, for 1 hour;

[0045] Pickling: usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com