Jute processing system

A processing system, jute technology, applied in textiles and papermaking, mechanical processing, fiber processing, etc., can solve the problems of large investment and unaffordable, and achieve cost-effective and cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

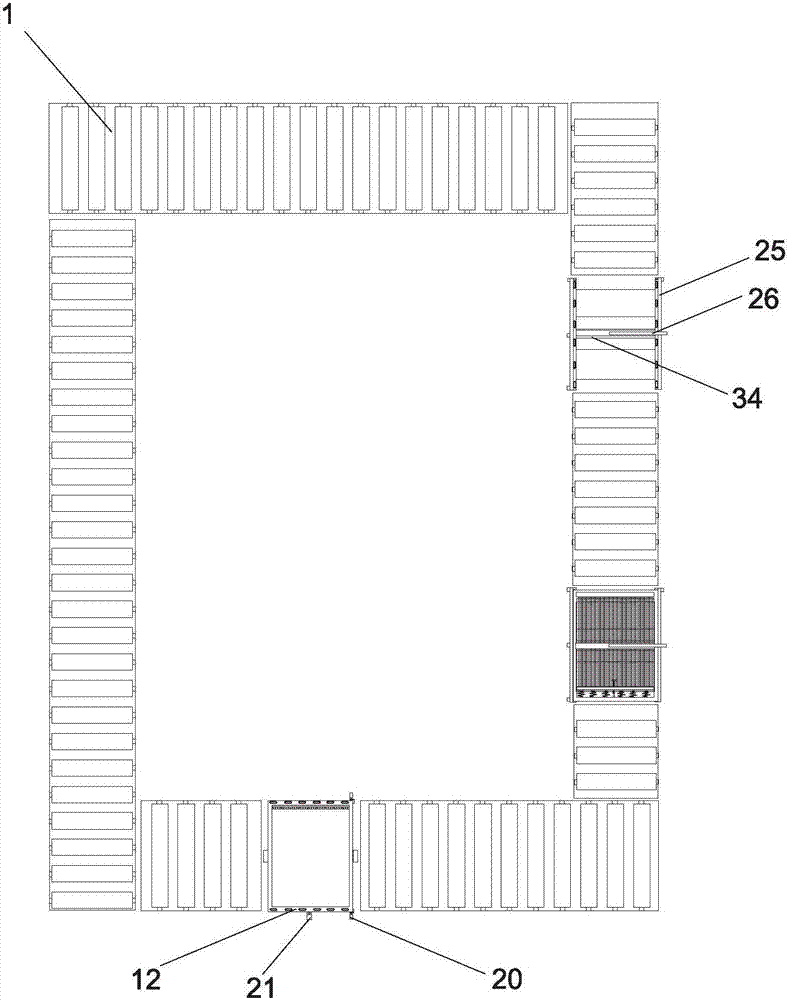

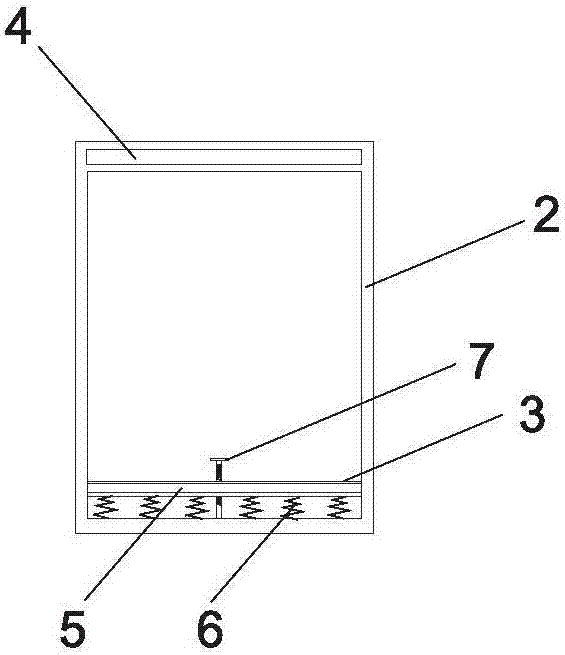

[0024] Such as Figure 1 to Figure 6 As shown, a jute processing system includes a jute carrier, an in and out station, a carding device, and a conveying device. The carding device includes a carding device and a combing device. The jute carrier is provided with a jute leather clamping mechanism and a tensioning mechanism , The conveying device includes a closed conveying rail 1. The conveying rail 1 is a roller table composed of a conveyor roller driven by a sprocket for conveying jute carriers. The width of the conveying rail 1 is adapted to the size of the jute carrier. There are two sides of the conveying rail 1. There is a baffle that is greater than the height of the jute carrier, and the jute carrier can be restricted when traveling on the conveying rail 1 so as not to deflect. The conveying rail 1 is enclosed in a rectangle, and each corner of the rectangular conveying rail 1 is provided with a reversing booster cylinder. The jute carrier is placed on the conveying rai...

Embodiment 2

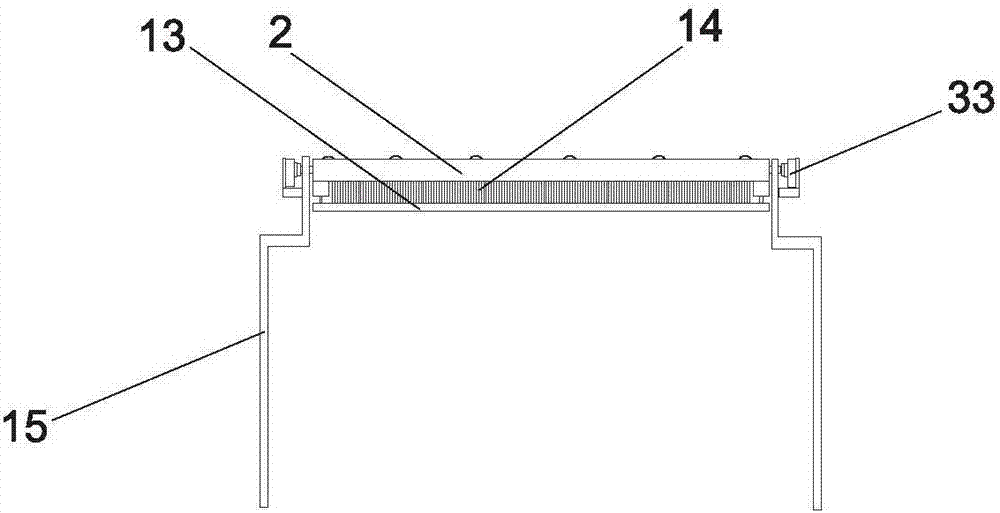

[0027] Such as Figure 7 As shown, the two support bars of the carrier bracket 25 and the connecting rod 34 form an H shape. The bottom of the connecting rod 34 is fixedly provided with a protruding threaded seat 35, the bottom of the threaded seat 35 is provided with a slider, and the reciprocating platform 23 is provided with a corresponding The sliding groove, the sliding block and the sliding groove are matched and connected to form a sliding connection. The threaded seat is threaded with a screw, and the end of the screw is connected to the reciprocating platform 23 in rotation. The sliding direction of the screw and the reciprocating platform 23 is perpendicular, and the front end of the screw penetrates the reciprocating platform 23. A stepping motor drive connection. The rest is the same as in Example 1.

[0028] In addition to the longitudinal combing effect of the combing head on the jute strips, the jute carrier can also change the lateral position under the control of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com