Linen spreading mechanism of mechanical arm

A technology of manipulator and opening and closing mechanism, which is applied in the direction of mechanical processing, combing machine, deburring device, etc., can solve the problems that the product quality cannot meet the new requirements of spinning technology, the uniformity of manual division is poor, and the cost is high. The effect of drying uniformly, improving product quality and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

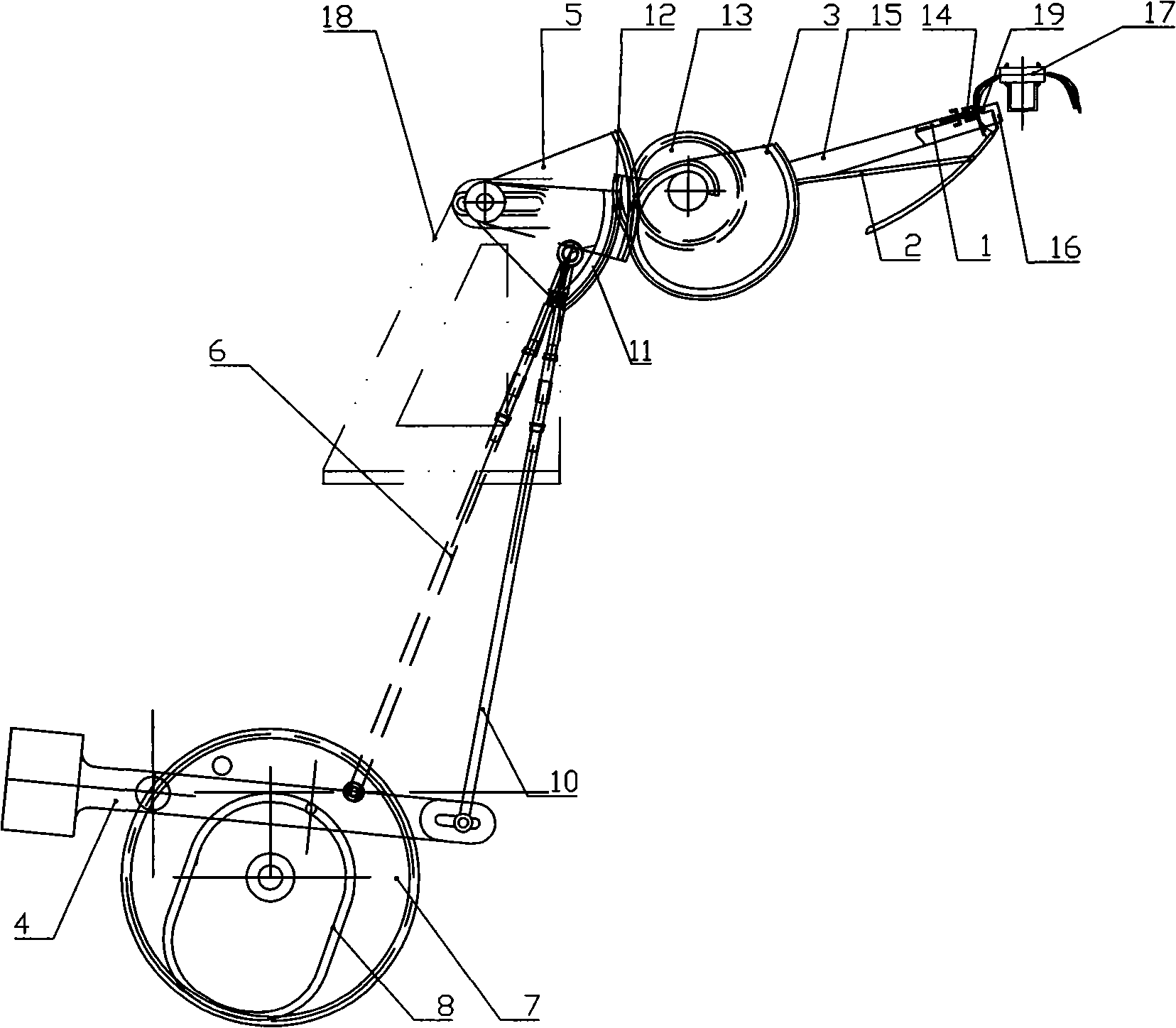

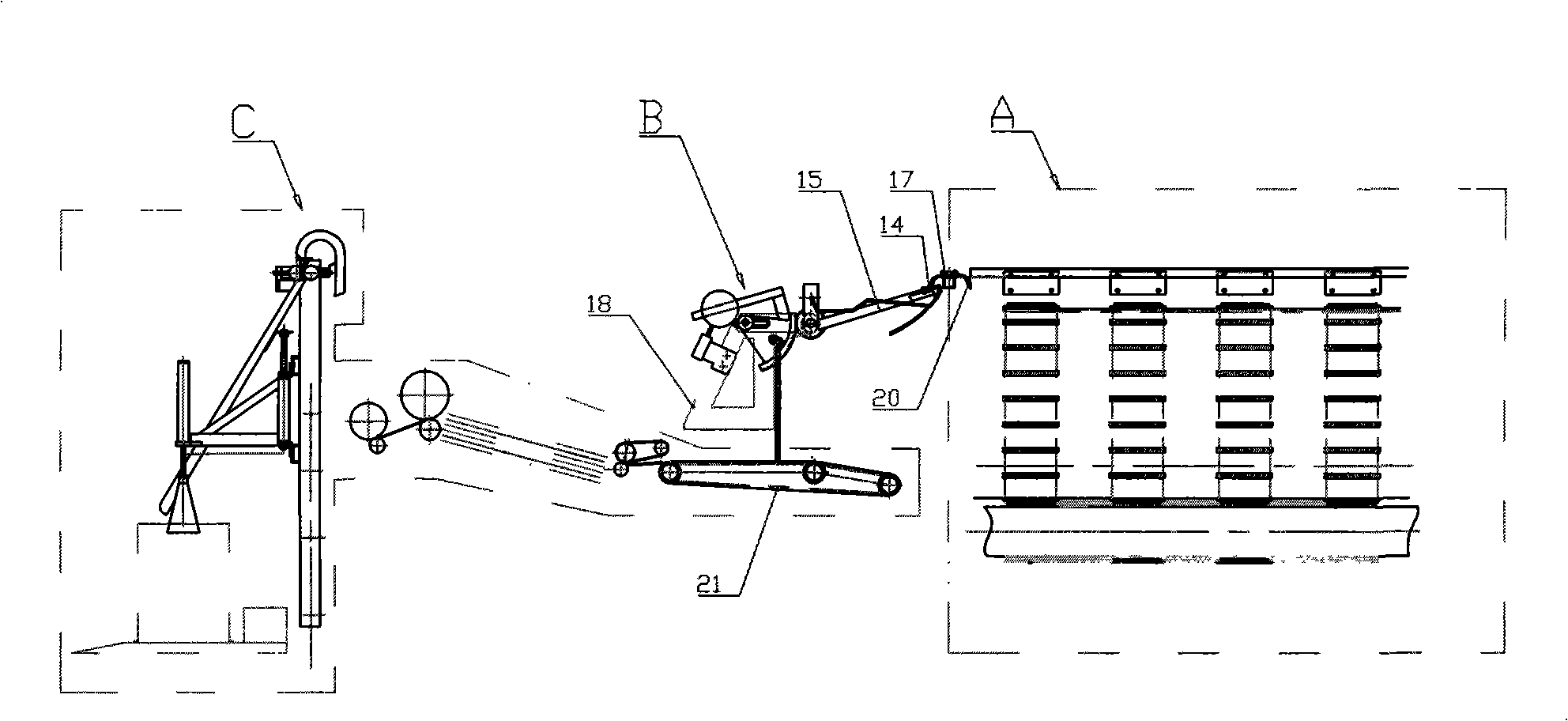

[0010] see figure 1 , the manipulator of the present invention lays hemp mechanism and is made of three main parts of splint swing mechanism, splint jaw opening and closing mechanism and air supply mechanism, wherein:

[0011] 1. Plywood swing mechanism: the cam 8 is coaxially connected with the gear 7, the middle part of the lever 4 is slidingly connected in the annular groove of the cam 8, one end of the lever 4 is hinged with the lower end of the connecting rod 10, and the upper end of the connecting rod 10 is connected with the sector Tooth plate 11 is hinged, and the top of this fan-shaped tooth plate 11 is hinged on the top of frame 18. Lever 4 rocks with the groove of cam 8 . One end of the lever 4 drives the connecting rod 10 to make the sector tooth plate 11 swing, and the sector tooth plate 11 drives the tooth plate 12 to swing, and makes the splint bracket 15, the splint connecting rod 1 and the splint assembly swing as a whole.

[0012] 2. The opening and closing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com