Automatic butt-joint device for pipeline test

An automatic docking and pipeline technology, applied in liquid tightness measurement using liquid/vacuum, metal processing, metal processing equipment, etc., can solve the problems of low production efficiency, high cost, and no way to realize automatic connection, etc., to avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

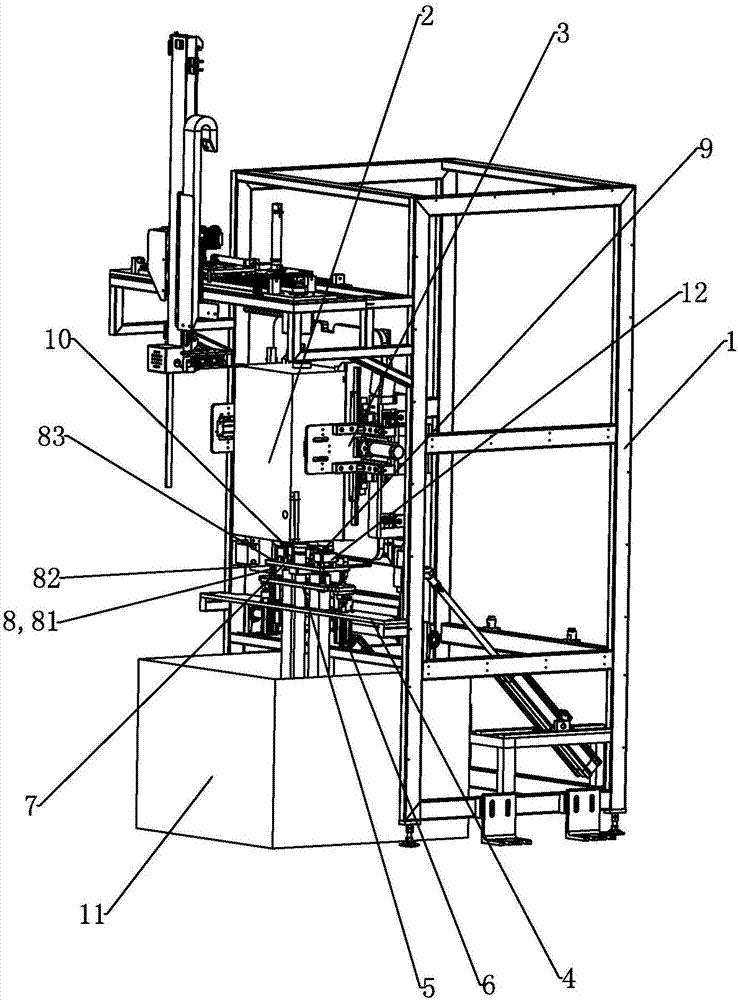

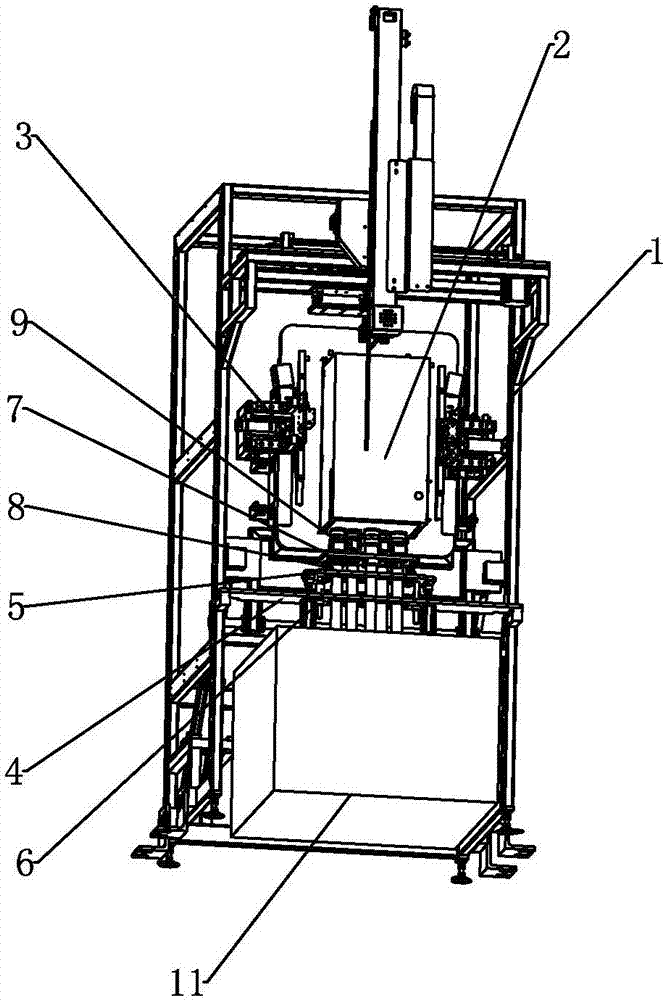

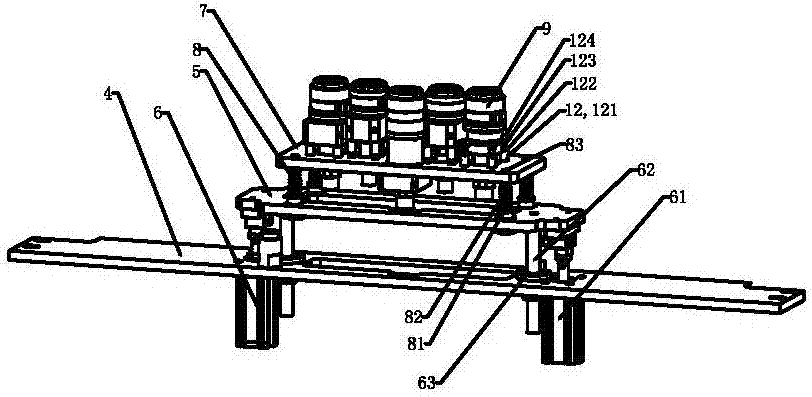

[0018] The technical solutions provided by the present invention will be described in more detail below in conjunction with the figures.

[0019] As shown in the figure, the automatic docking device for pipeline testing includes a bracket 1, and a clamping mechanism 3 that can clamp the workpiece 2 to be tested is provided on the bracket 1. In this case, the clamping mechanism 3 adopts two sides. Two cylinders are used to drive the clamping and loosening of the two clamping plates, and the workpiece to be clamped is a wall-hung furnace. A fixed plate 4 is arranged on the support 1 , a liftable sliding plate 5 is arranged above the fixed plate 4 , and a first driving mechanism 6 for driving the sliding plate 5 to lift is arranged on the fixed plate 4 . A buffer plate 7 is provided above the slide plate 5, a pressing mechanism 8 that guides and presses the buffer plate 7 is provided on the slide plate 5, and a plurality of screw ports 10 that are connected to the test workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com