Mechanical device for automatically opening flax round packages from flax

A technology of bale unpacking machine and flax, which is applied in the direction of fiber unpacking, combing machine, mechanical treatment, etc. It can solve the problems of high labor intensity, manual beam splitting, low labor efficiency, etc., and achieve uniform flax bundle size, Evenly rolled and less messy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

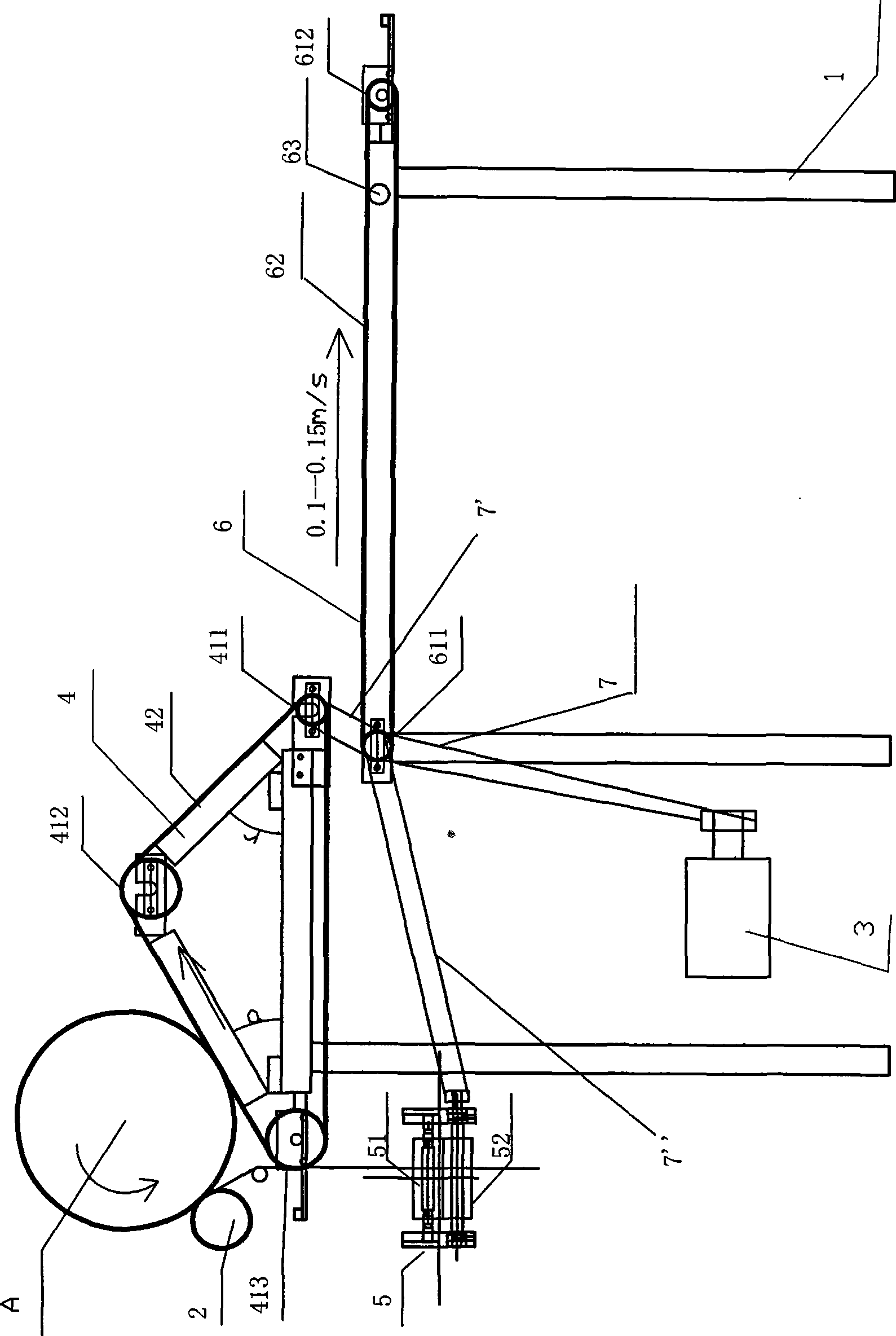

[0010] see figure 1 , Fig. 2, the present invention comprises frame 1, guide roller 2, motor 3, round bag unwinding device 4, stay rope device 5 and delivery device 6, and round bag unwinding device 4 comprises three unwinding guide rollers 41 and a The unwinding belt 42, the pull rope device 5 includes a top roller 51 and an iron roller 52, and the conveying device 6 includes a conveying guide roller 61 and a conveying belt 62. The motor 3 is installed on the frame 1, and is connected with the conveying guide roller 61 in the conveying device 6 through the transmission belt 7, and the conveying guide roller 61 is connected with the unwinding guide roller 41 in the round bag unwinding device 4 through the transmission belt 7' Connect, conveying guide roller 61 is connected with the iron roller 52 in the stay rope device 5 by drive belt 7 ".

[0011] A triangular transmission device composed of the three unwinding guide rollers 41 and the unwinding belt 42 is preferably an obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com