Sheep wool opening and carding complete equipment

A complete set of equipment and technology for sheep wool, applied in the field of textile machinery, can solve the problems of uneven cashmere, affecting opening, removing roughness, removing impurities and carding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

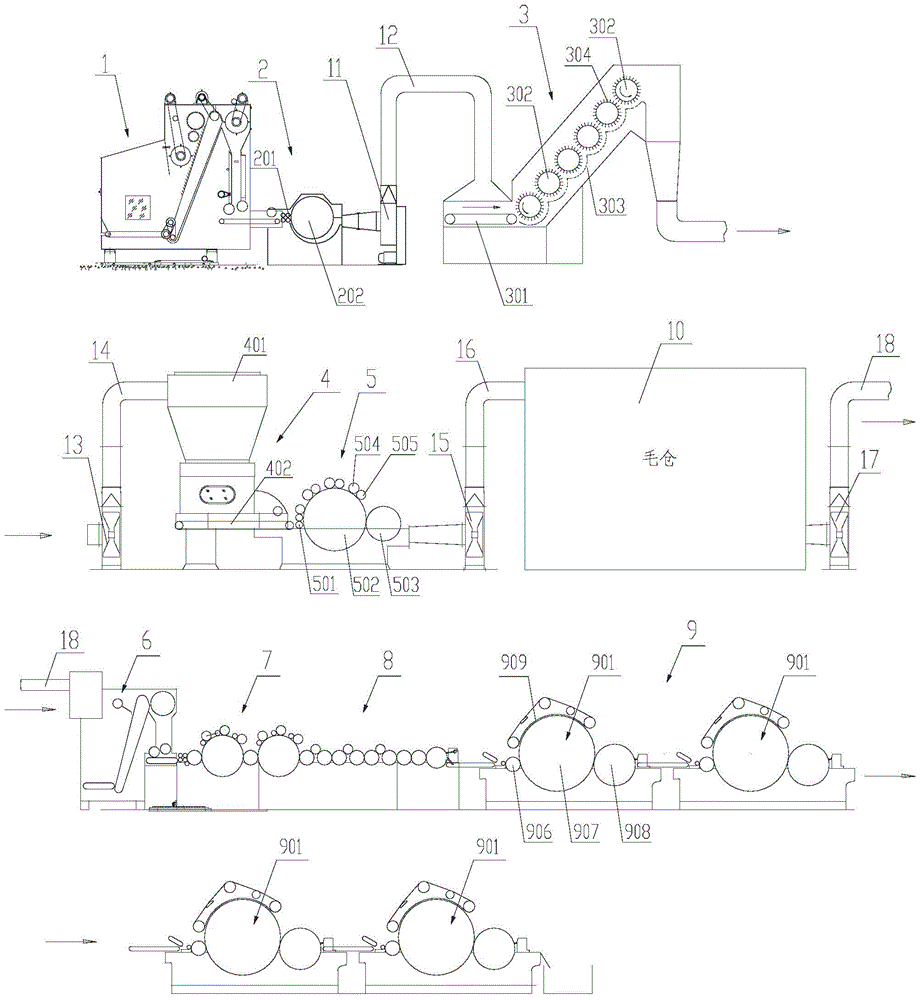

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] combine figure 1 As shown, the complete set of cashmere opening and carding equipment includes the second feeding mechanism 1, the second opening mechanism 2, the third opening mechanism 3, the closing mechanism 4, and the second carding mechanism 5 arranged in sequence from front to back. , Mao bin 10, the first feeding mechanism 6, the first loosening mechanism 7, the first coarse and impurity removal mechanism 8 and the first carding mechanism 9.

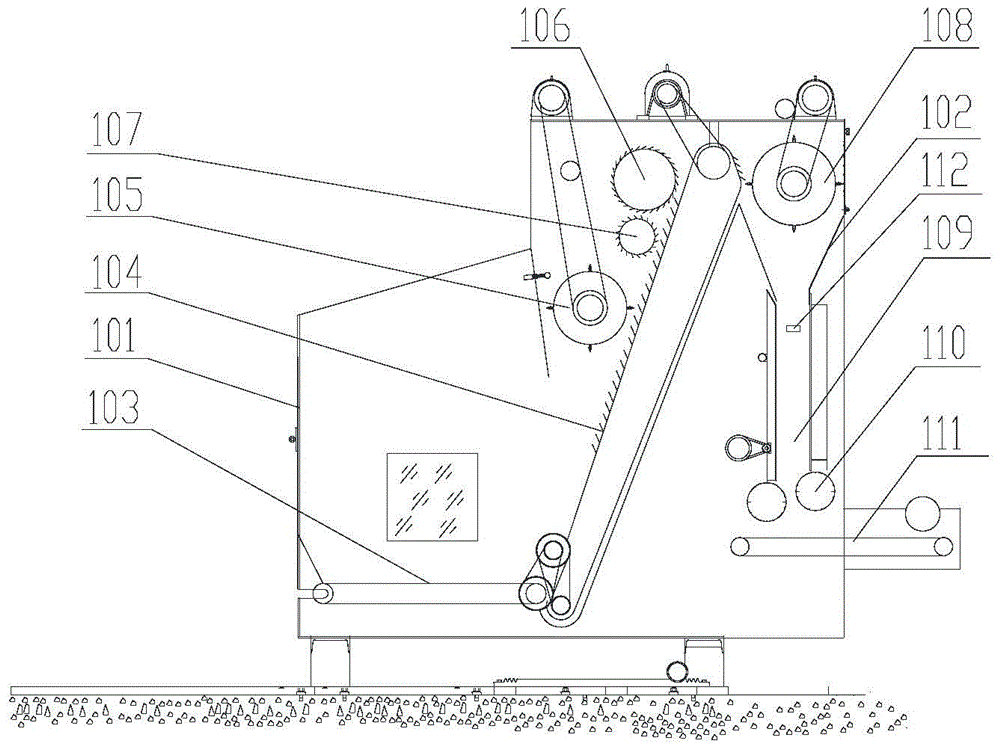

[0024] Such as figure 2 As shown, the second feeding mechanism 1 includes a wool feeding box 101 and a vibrating box 102 . The first flat curtain 103 and the first oblique curtain 104 are arranged inside the hair feeding box 101, the middle part front of the first oblique curtain 104 is provided with an even rake 105, and the upper front of the first oblique curtain 104 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com