Compact chlorine-resistant composite nano-filtration membrane preparation method

A composite nanofiltration membrane and compact technology, which is applied in the field of preparation of compact chlorine-resistant composite nanofiltration membranes, can solve the problems of inability to continue to use, destroy the nanofiltration membrane, damage, etc., so as to ensure the tolerance performance and high interception performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First, the polysulfone microporous membrane composed of non-woven fabric and polysulfone support layer is immersed in the aqueous solution containing 0.5wt% piperazine, and the excess solution on the surface is removed with a rubber roller. The organic phase solution of % trimesoyl chloride was contacted for 40 seconds, and after removing excess solution on the surface with a rubber roller, it was again contacted with an aqueous solution containing 0.5wt% polyvinyl alcohol for 1 minute, and finally heat-treated in an oven at 80°C for 5 minutes to obtain Compact chlorine-resistant composite nanofiltration membrane.

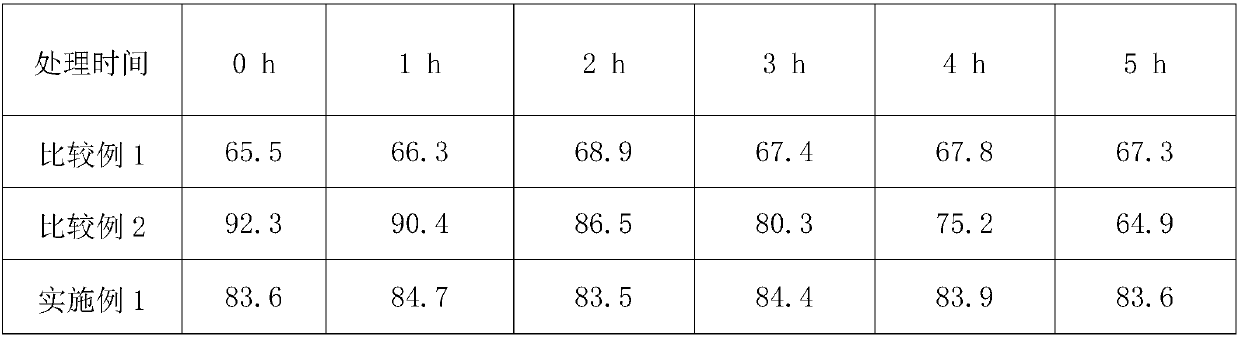

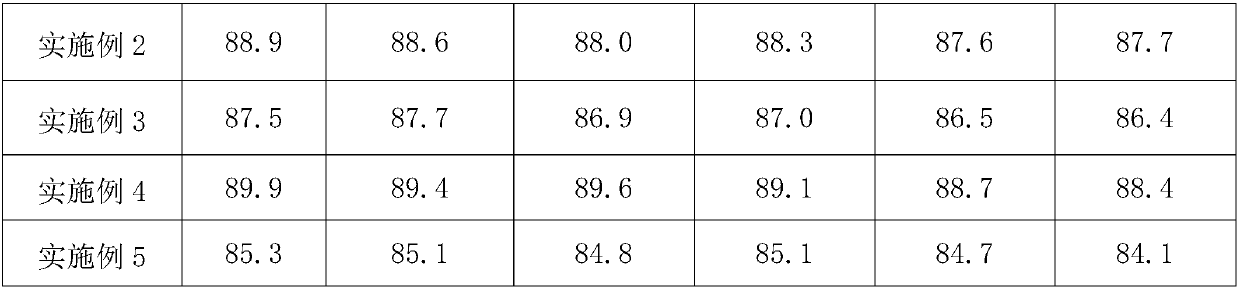

[0021] Under the conditions of NaCl concentration of 500mg / l, pressure of 0.5MPa, temperature of 25°C, and pH value of 7.0 to 8.0, the inorganic salt removal rate and permeation flux of the composite nanofiltration membrane were tested; the resistance of the composite nanofiltration membrane Chlorine performance is evaluated by testing the separation perform...

Embodiment 2

[0023] First, the polysulfone microporous membrane composed of non-woven fabric and polysulfone support layer is immersed in the aqueous solution containing 0.5wt% piperazine, and the excess solution on the surface is removed with a rubber roller. The organic phase solution of % trimesoyl chloride was contacted for 40 seconds, and after removing excess solution on the surface with a rubber roller, it was again contacted with an aqueous solution containing 1.0wt% polyvinyl alcohol for 1 minute, and finally heat-treated in an oven at 80°C for 5 minutes to obtain Compact chlorine-resistant composite nanofiltration membrane.

[0024] Under the conditions of NaCl concentration of 500mg / l, pressure of 0.5MPa, temperature of 25°C, and pH value of 7.0 to 8.0, the inorganic salt removal rate and permeation flux of the composite nanofiltration membrane were tested; the resistance of the composite nanofiltration membrane Chlorine performance is evaluated by testing the separation perform...

Embodiment 3

[0026] First, the polysulfone microporous membrane composed of non-woven fabric and polysulfone support layer is immersed in the aqueous solution containing 0.5wt% piperazine, and the excess solution on the surface is removed with a rubber roller. The organic phase solution of % trimesoyl chloride was contacted for 40 seconds, and after removing excess solution on the surface with a rubber roller, it was again contacted with an aqueous solution containing 1.0wt% sodium carboxymethylcellulose for 1 minute, and finally heat-treated in an oven at 80°C for 5 Minutes to obtain a compact chlorine-resistant composite nanofiltration membrane.

[0027] Under the conditions of NaCl concentration of 500mg / l, pressure of 0.5MPa, temperature of 25°C, and pH value of 7.0 to 8.0, the inorganic salt removal rate and permeation flux of the composite nanofiltration membrane were tested; the resistance of the composite nanofiltration membrane Chlorine performance is evaluated by testing the sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com