Preparation method of chlorine-resistant composite ceramic nano-filtration membrane

A technology of composite ceramics and nanofiltration membranes, applied in the field of water purification, can solve problems such as unusable, damaged nanofiltration membranes, and degradation of membrane performance, and achieve the effect of ensuring tolerance and high retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

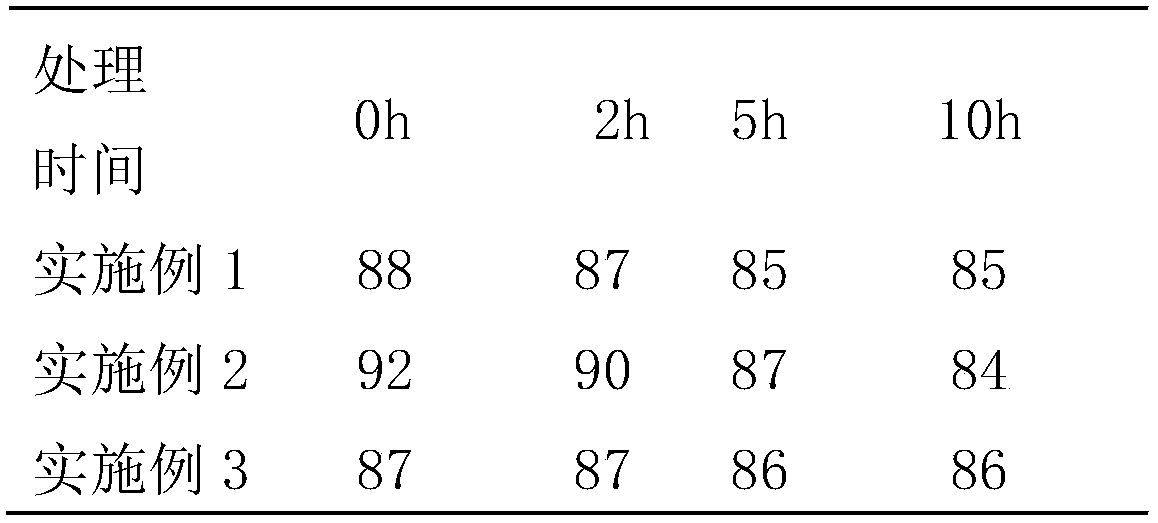

Examples

Embodiment 1

[0017] S1. Preparation of ceramic membrane:

[0018] 1) Each raw material is weighed according to the composition of the following parts by weight: 120 parts of alumina powder, 40 parts of silicon carbide, 300 parts of boron nitride, 70 parts of silicon dioxide, 10 parts of antioxidant, and 30 parts of nano-titanium oxide additive;

[0019] 2) adding alumina powder, silicon carbide, boron nitride and silicon dioxide into a ball mill, and performing dry mixing and ball milling for 15 hours to obtain a mixed material;

[0020] 3) Mix and grind the antioxidant and additives to 200 mesh, add the mixture obtained in step 2) and mix evenly, put it in a high-temperature furnace, heat to 1500°C for 4 hours in a vacuum and dragging atmosphere, and sinter the to room temperature.

[0021] S2. Chlorine-resistant composite ceramic nanofiltration membrane:

[0022] First, the ceramic membrane prepared in step S1 is immersed in an aqueous solution containing 0.5wt% piperazine, and after r...

Embodiment 2

[0024] S1. Preparation of ceramic membrane:

[0025] 1) Each raw material is weighed according to the composition of the following parts by weight: 130 parts of alumina powder, 30 parts of silicon carbide, 30 parts of boron nitride, 80 parts of silicon dioxide, 20 parts of antioxidant, and 10 parts of nano-zinc oxide additive;

[0026] 2) adding alumina powder, silicon carbide, boron nitride and silicon dioxide into a ball mill, and performing dry mixing and ball milling for 15 hours to obtain a mixed material;

[0027] 3) Mix and grind the antioxidant and additives to 100 mesh, add the mixture obtained in step 2) and mix evenly, put it in a high-temperature furnace, heat to 1500°C for 4 hours in a vacuum and dragging atmosphere, and sinter the to room temperature.

[0028] S2. Preparation of chlorine-resistant composite ceramic nanofiltration membrane:

[0029] First, the ceramic membrane prepared in step S1 is immersed in an aqueous solution containing 0.5wt% piperazine, a...

Embodiment 3

[0031] S1. Preparation of ceramic membrane:

[0032] 1) Weigh each raw material according to the composition of the following parts by weight: 150 parts of alumina powder, 35 parts of silicon carbide, 33 parts of boron nitride, 77 parts of silicon dioxide, 13 parts of antioxidant, 10 parts of nano-titanium oxide additive, nano-oxidized 10 parts of zinc additive;

[0033] 2) adding alumina powder, silicon carbide, boron nitride and silicon dioxide into a ball mill, and performing dry mixing and ball milling for 10-15 hours to obtain a mixed material;

[0034] 3) Mix and grind the antioxidant and additives to 100-200 mesh, and then add the mixture obtained in step 2) to dry it out. After mixing evenly, put it into a high-temperature furnace and heat it to 700-1500°C in a vacuum and dragging atmosphere for sintering 2-4 hours, it will come to room temperature.

[0035] S2. Preparation of chlorine-resistant composite ceramic nanofiltration membrane:

[0036] First, the ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com