Cladding glass for flexible optical fiber image bundles with high resolution ratio, and preparation method thereof

An optical fiber image transmission beam and cladding glass technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult glass matching, difficult preparation of acid-soluble cladding glass, poor acid-dissolving effect, etc., and achieve good matching ability. , good chemical stability, good anti-devitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

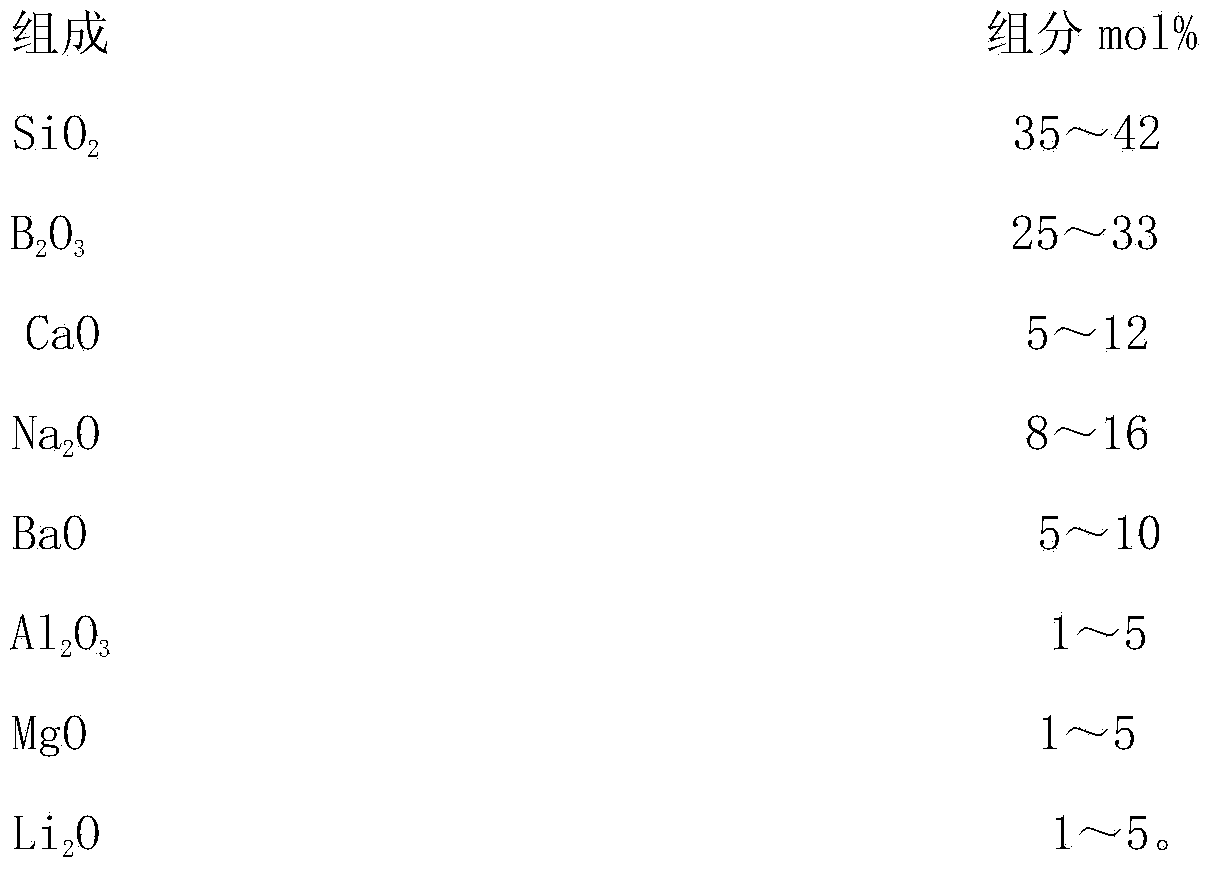

[0025] Commercially available analytically pure chemical reagents are used to form the ingredients according to the formula in Table 1:

[0026] Table 1

[0027] composition

[0028] Accurately calculate and weigh 800g of raw materials, stir evenly and make batches for later use. Add the batch materials in several times, and fully melt when the electric furnace is heated to 1350 °C. After completion, the electric furnace is heated to 1400°C, stirred until the viscosity is moderate, and after clarification for about 1 hour, the temperature is slowly lowered to 1200°C, and the discharged material is poured into a mold for molding and then annealed. The glass refractive index n d (λ=587.6nm)=1.534, the acid dissolution rate in 0.5N nitric acid and hydrochloric acid mixture is 25.25mg.cm -2 .h -1 , has a very good acid dissolution rate, and has a good wire drawing effect with the mandrel and the middle cladding sleeve, and can smoothly draw the monofilament of the re...

Embodiment 2

[0030] Adopt commercially available analytical pure chemical reagent, according to the prescription composition in Table 2 batching:

[0031] Table 2

[0032] composition

[0033] Accurately calculate and weigh 800g of raw materials, stir evenly and make batches for later use. Add the batch materials in several times, and fully melt when the electric furnace is heated to 1350 °C. After completion, the electric furnace is heated to 1400°C, stirred until the viscosity is moderate, and after clarification for about 1 hour, the temperature is slowly lowered to 1200°C, and the discharged material is poured into a mold for molding and then annealed. The glass refractive index n d (λ=587.6nm)=1.535, the acid dissolution rate of the glass block in the mixed solution of 0.5N nitric acid and hydrochloric acid is 17.25mg.cm -2 .h -1 , has a very good acid dissolution rate, and has a good wire drawing effect with the mandrel and the middle cladding sleeve, and can smoothly d...

Embodiment 3

[0035] Adopt commercially available analytical pure chemical reagent, according to the prescription composition in Table 3 batching:

[0036] table 3

[0037] composition

[0038] Accurately calculate and weigh 800g of raw materials, stir evenly and make batches for later use. Add the batch materials in several times, and fully melt when the electric furnace is heated to 1350 °C. After completion, the electric furnace is heated to 1400°C, stirred until the viscosity is moderate, and after clarification for about 1 hour, the temperature is slowly lowered to 1200°C, and the discharged material is poured into a mold for molding and then annealed. The glass refractive index n d (λ=587.6nm)=1.559, the acid dissolution rate of the glass block in the mixed solution of 0.5N nitric acid and hydrochloric acid is 20.51mg.cm -2 .h -1 , has a very good acid dissolution rate, and has a good wire drawing effect with the mandrel and the middle cladding sleeve, and can smoothly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com