Finite element compensation method for deformation of numerical control processed part

A compensation method and finite element technology, applied in the direction of program control, computer control, comprehensive factory control, etc., can solve the problems of machining error, deformation, difficult design and production of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

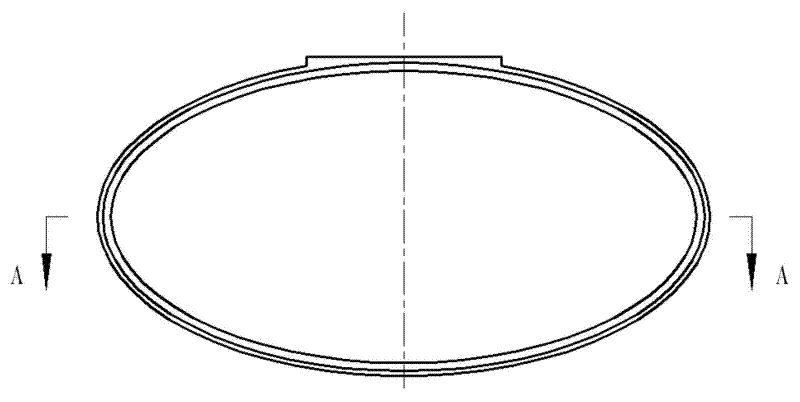

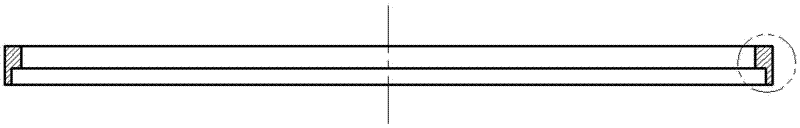

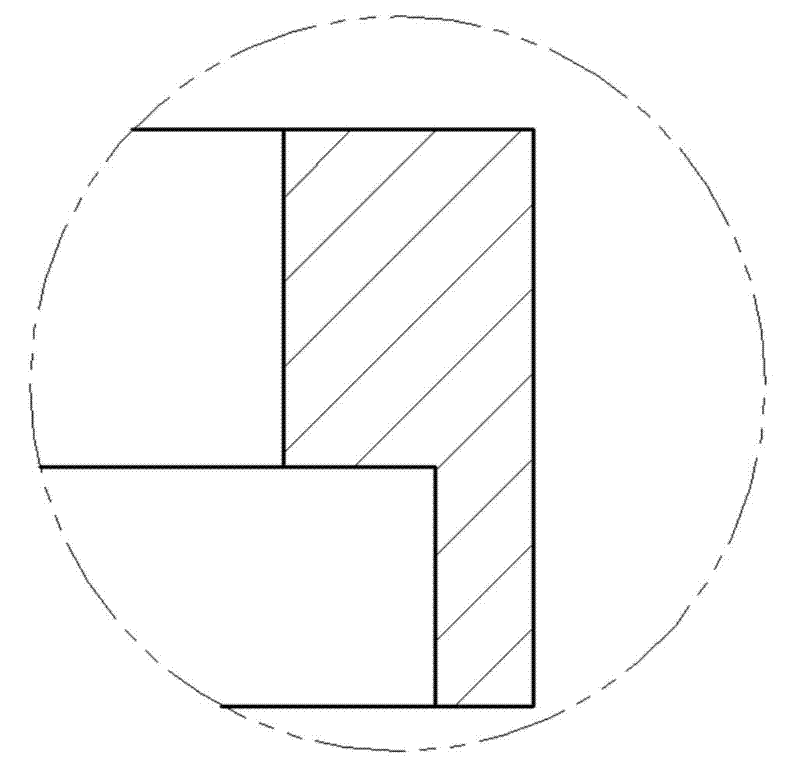

[0023] The specific implementation of the finite element compensation method for the deformation of the numerically controlled machining parts of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] See attached Figure 5 , a finite element compensation method for deformation of CNC machining parts, the steps are as follows: (1) use modeling software to save the part as a digital model; (2) convert the digital model to finite element analysis software to establish a finite element model; (3) ) Define the unit, section and material, and complete the unit mesh division; (4) Add loads and constraints according to the working conditions, and calculate the deformation of the part caused by the clamping force; (5) Output the surface or line to be processed The amount of deformation of each node; (6) According to the amount of deformation, use the modeling software to draw the shape of the part after being clamped; (7) Carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com