Moulding process of diagonal end ring of transformer and special mould

A slanted end ring and transformer technology, applied in the field of transformers, can solve the problems of difficulty in iron molds, potential safety hazards, and easy to disengage the tight wrapping device, and achieve the effects of reducing labor intensity, improving operational safety, and reducing the frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

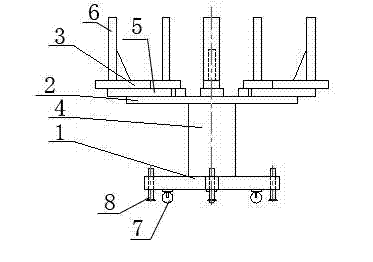

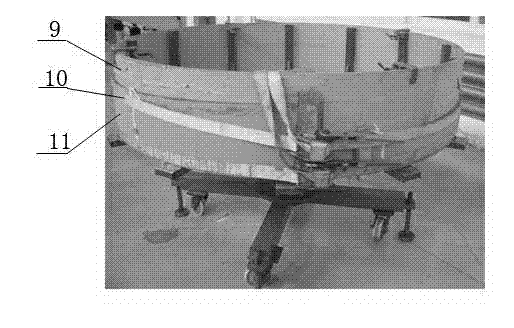

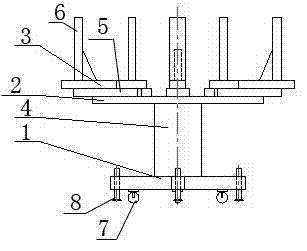

[0013] Transformer oblique end ring forming mold, including bracket 1, disc 2, adjustment mechanism, rotation mechanism 4, the adjustment mechanism is composed of fixed plate 5, expansion plate 3, iron stay 6 and scale, the expansion plate is set on the fixed plate On the top, the iron stays are vertically set on the telescopic plate, and the scale is set on the fixed plate; the disc is set on the bracket through the rotating mechanism, and there are multiple round holes on the disc, which are divided into twenty-four groups on average along the circumferential direction. , each set of round holes fixes a fixed plate. A roller 7 is arranged below the support, which can easily adjust the placement position of the mold, and a positioning supporter 8 is also arranged beside the roller. The rotating mechanism is composed of bearings, which can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com