Self-assembling movable template for partition wall in main structure of subway station and half-cover excavation method section

A technology of main structure and cover and excavation method, which is applied to underwater structures, infrastructure engineering, formwork/formwork/work frame, etc. The effect of simple materials, cost saving, and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

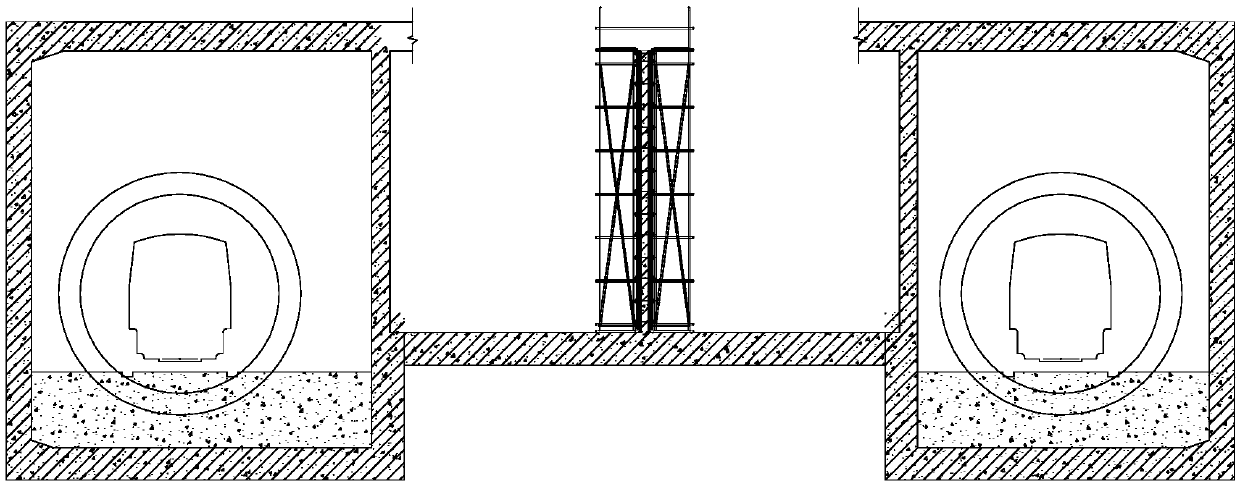

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

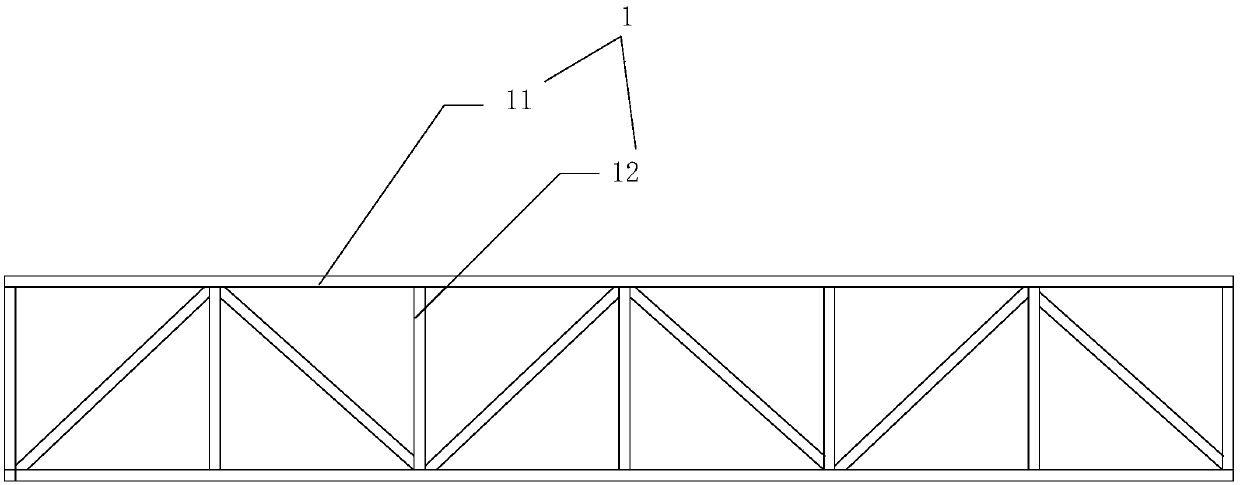

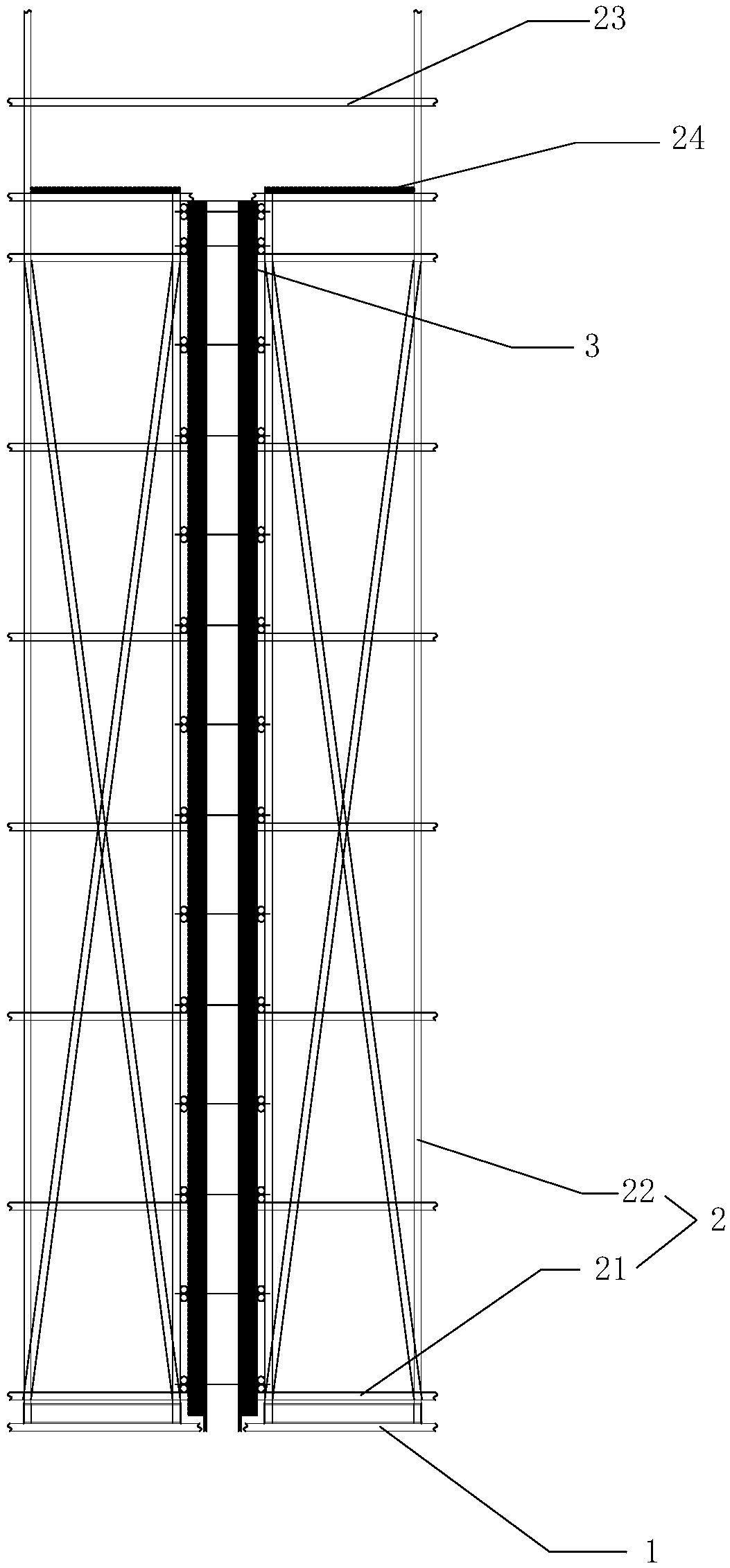

[0024] refer to Figure 1-Figure 3 , the partition wall self-assembled mobile formwork in the main structure of the subway station and the half-cover excavation section, including: two bases 1 set at intervals, brackets 2 set on each base 1 and brackets 2 set on each panel 3;

[0025] The base 1 is welded by channel steel, two first channel steels 11 are arranged in parallel and spaced apart in the length direction, and a plurality of second channel steels 12 are arranged in parallel and spaced apart in the width direction, and the distance between the two first channel steels 11 is It is the same as the distance between two adjacent second channel steels 12; the two ends of the second channel steels 12 are respectively welded and fixed with the first channel steels 11;

[0026] The support 2 is erected by a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com