Drilling and blasting tunnel structure adopting prefabricated inverted arch

A prefabricated assembly and tunnel structure technology, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve problems affecting the normal operation of high-speed rail, cracking and deformation of ballast beds, and speed limit of tunnels, so as to optimize tunnel section type and structural size, and ensure Effects of early sealing and improving the degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

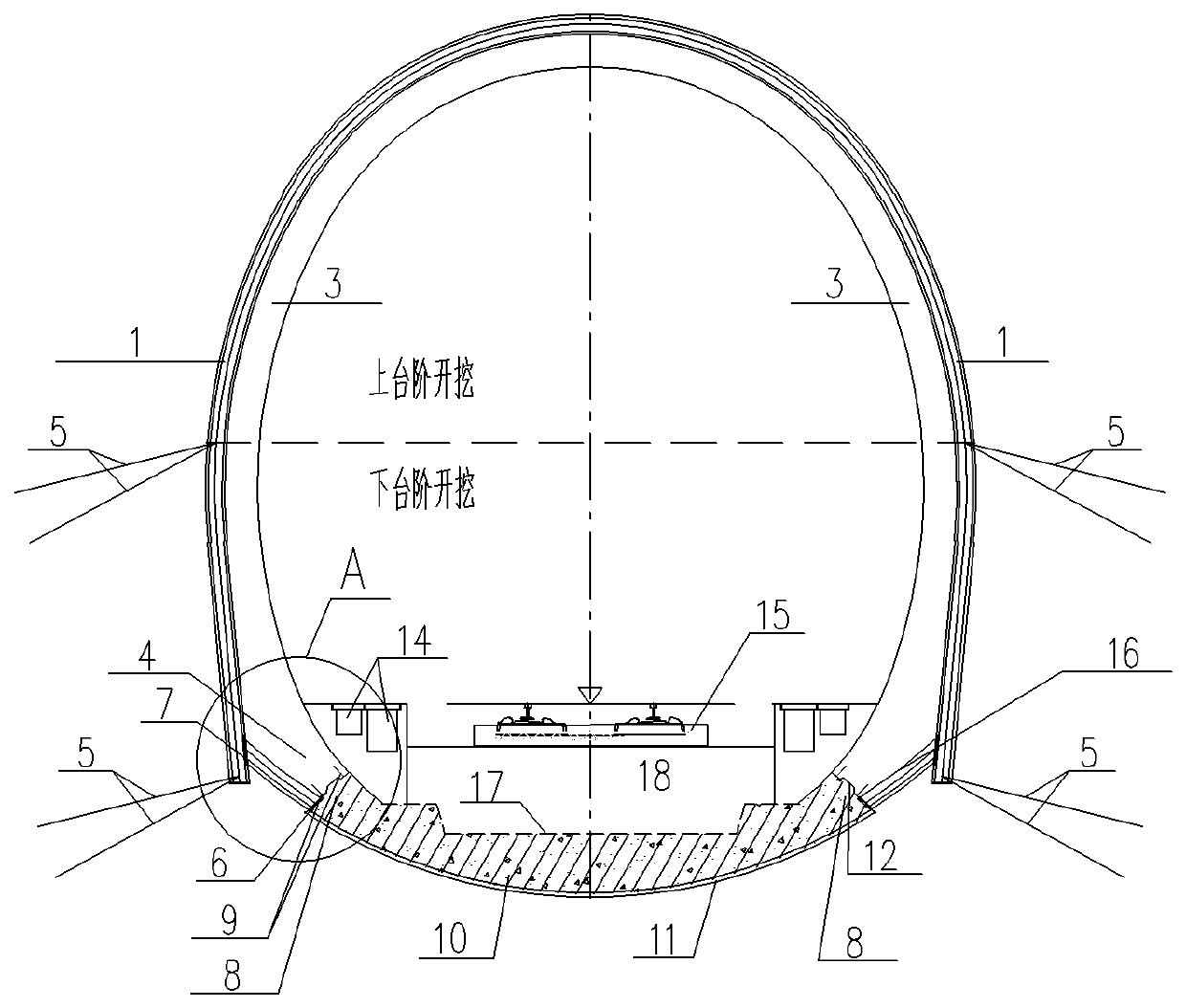

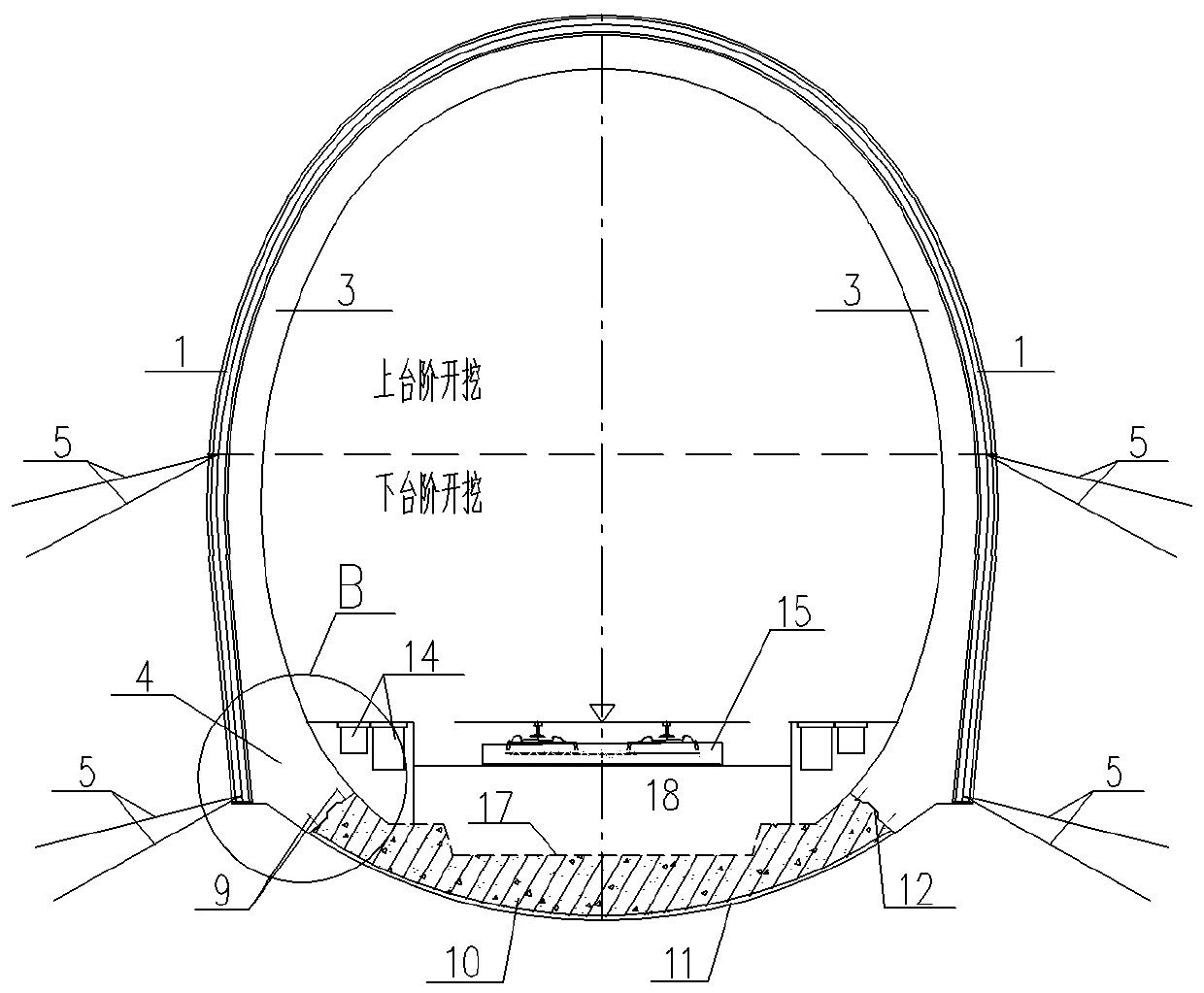

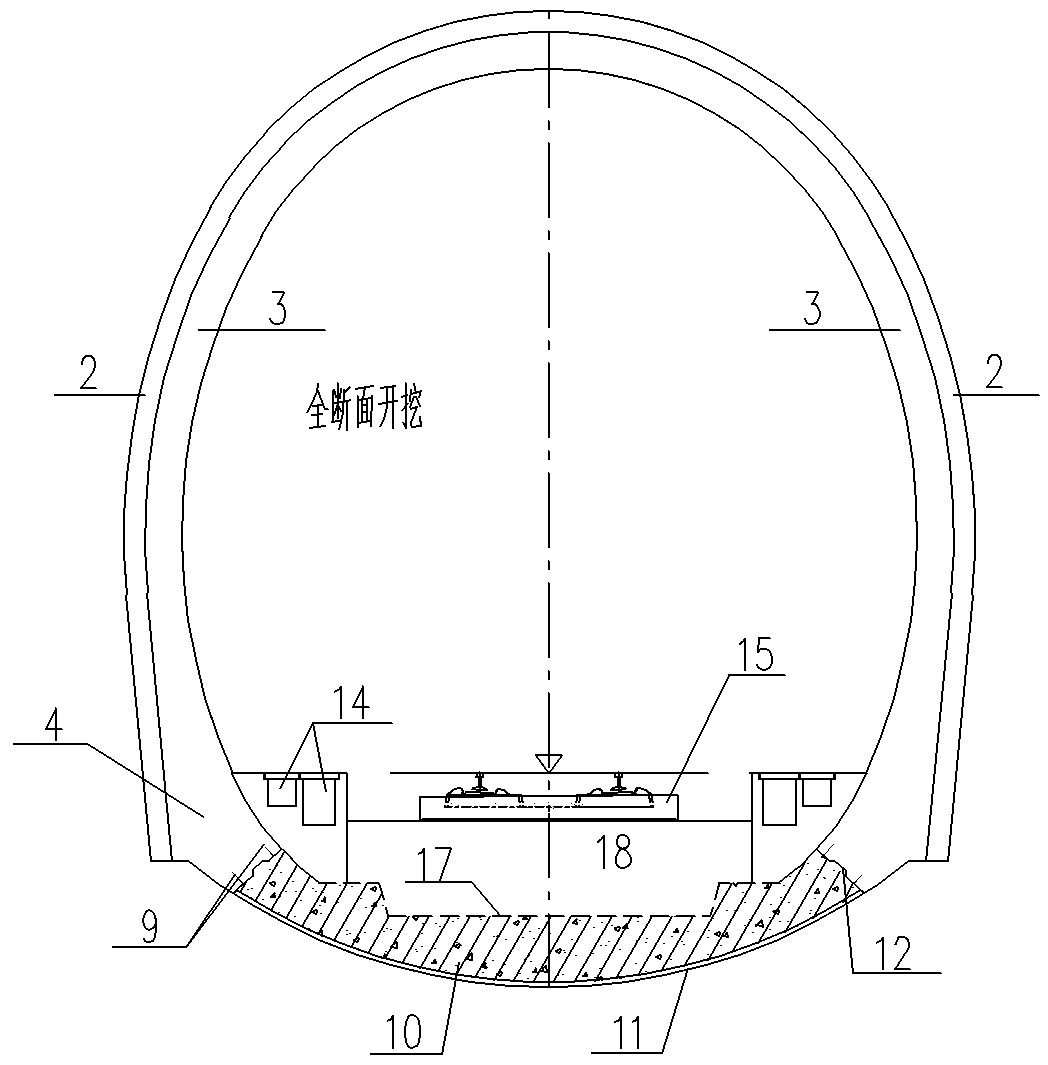

[0031] The present invention will be described in detail below in combination with specific embodiments.

[0032] Prefabricated buildings are a major change in construction methods, which are conducive to saving resources, reducing construction pollution, improving the working environment, increasing production efficiency, and promoting standardized construction. Drilling and blasting tunnels can replace the traditional inverted arch trestle model after adopting the assembled inverted arch. After the inverted arch is prefabricated and assembled, it can be closely followed by the excavation tunnel face to achieve rapid installation and construction. While ensuring the quality of the inverted arch, it also improves Tunnel security. Due to various factors, the current construction method of drilling and blasting tunnels is still mainly cast-in-place, and the proportion of drilling and blasting prefabricated tunnel construction is still very low, which is still far behind the nati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com