A Novel Two-Element Unilateral Expansion Nozzle

A unilateral expansion nozzle and unilateral technology, applied in the direction of jet propulsion devices, machines/engines, etc., can solve the problems of weak stealth ability, increased nozzle height and length, and inability to effectively block the front-end hot-end components, etc., to achieve reliable The effect of high performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

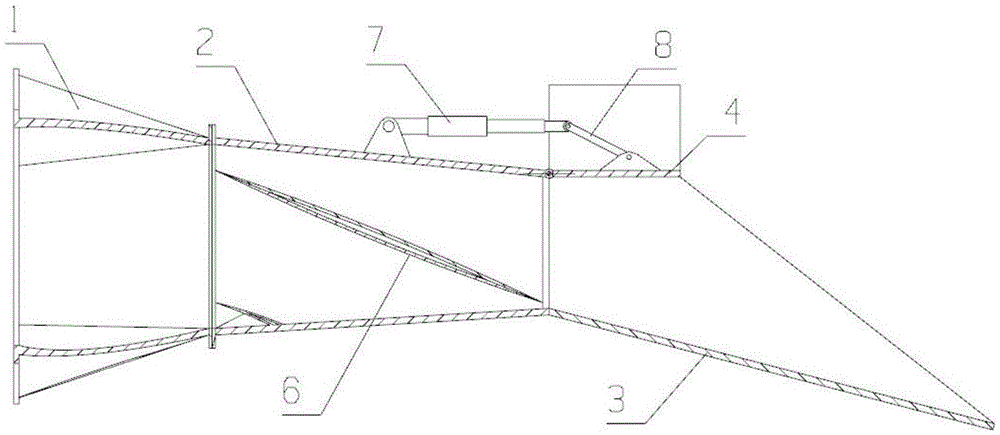

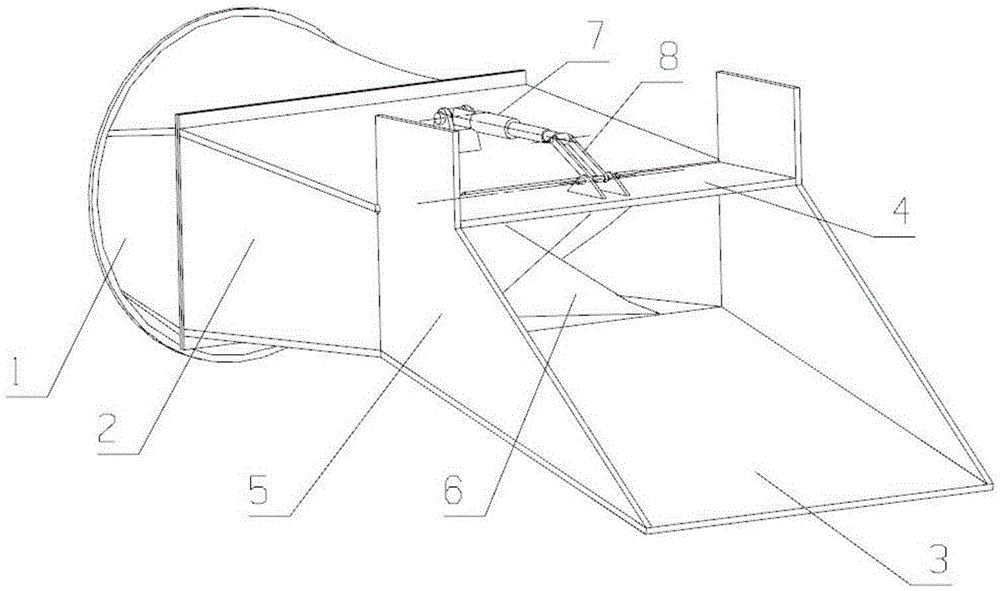

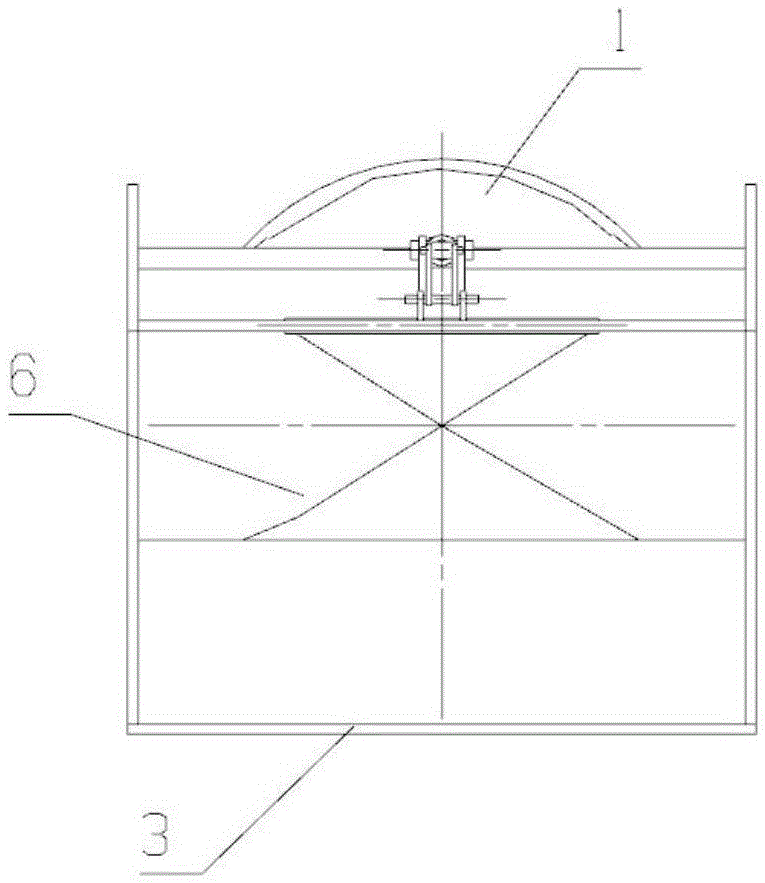

[0026] A novel two-unit unilateral expansion nozzle mainly includes a circular and square cylinder body 1, a unilateral expansion wall 3, an adjustment plate 4, a side wall 5 of an expansion section, and a blade-shaped structure 6 for shielding swirling flow.

[0027] The front end of the round and rotating square cylinder 1 is connected with the engine as a supporting member of the entire nozzle, and the rear end is connected with the single-side expansion wall 3, the adjustment plate 4 and the side wall 5 of the expansion section. The cross-sectional area of the rounded square cylinder 1 decreases gradually, forming the convergent section of the dual-unit unilateral expansion nozzle.

[0028] The unilateral expansion wall 3, the regulating plate 4 and the expansion section side wall 5 form the expansion section of the dual-unit unilateral expansion nozzle. The front end of the adjustment plate 4 is connected with the circular cylinder body 1 through a rotating pair, and th...

Embodiment 2

[0031] A novel two-element unilateral expansion nozzle mainly includes a rounded square cylinder body 1, a converging section 2, a unilateral expansion wall 3, an adjustment plate 4, a side wall 5 of an expansion section and a blade-shaped structure 6 for shielding swirling flow.

[0032] The front end of the round and rotating square cylinder 1 is connected with the engine as a supporting member of the entire nozzle, and the rear end is connected with the converging section 2 . The cross-sectional area of the round-to-square cylinder body 1 is constant in size, and serves as a transition section where the cross-section of the dual-unit unilateral expansion nozzle changes from a circle to a square.

[0033] The rear end of the converging section 2 is connected with the unilateral expansion wall 3 , the regulating plate 4 and the side wall 5 of the expansion section.

[0034] The unilateral expansion wall 3, the regulating plate 4 and the expansion section side wall 5 form th...

Embodiment 3

[0037] A novel two-element unilateral expansion nozzle mainly includes a rounded square cylinder body 1, a converging section 2, a unilateral expansion wall 3, an adjustment plate 4, a side wall 5 of an expansion section and a blade-shaped structure 6 for shielding swirling flow.

[0038] The front end of the round and rotating square cylinder 1 is connected with the engine as a supporting member of the entire nozzle, and the rear end is connected with the converging section 2 . The cross-sectional area of the rounded square cylinder 1 decreases gradually, and constitutes a part of the converging section of the binary unilateral expansion nozzle.

[0039] The rear end of the converging section 2 is connected with the unilateral expansion wall 3 , the regulating plate 4 and the side wall 5 of the expansion section.

[0040] The unilateral expansion wall 3, the regulating plate 4 and the expansion section side wall 5 form the expansion section of the dual-unit unilateral expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com