A New Binary Adjustable Convergent Nozzle

A nozzle and a new type of technology, applied in the field of new binary adjustable convergent nozzles, can solve the problems of not being able to block the front-end hot-end components, large size, long length, etc., achieve good stealth ability, small outline size, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

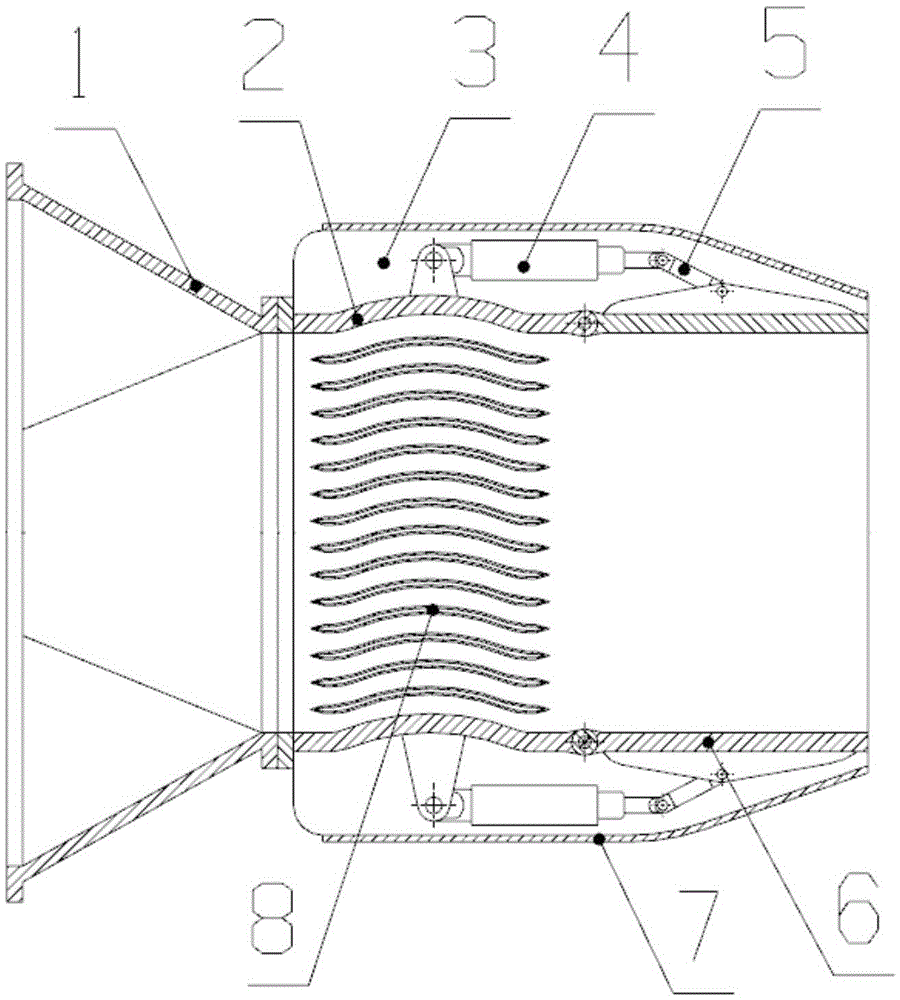

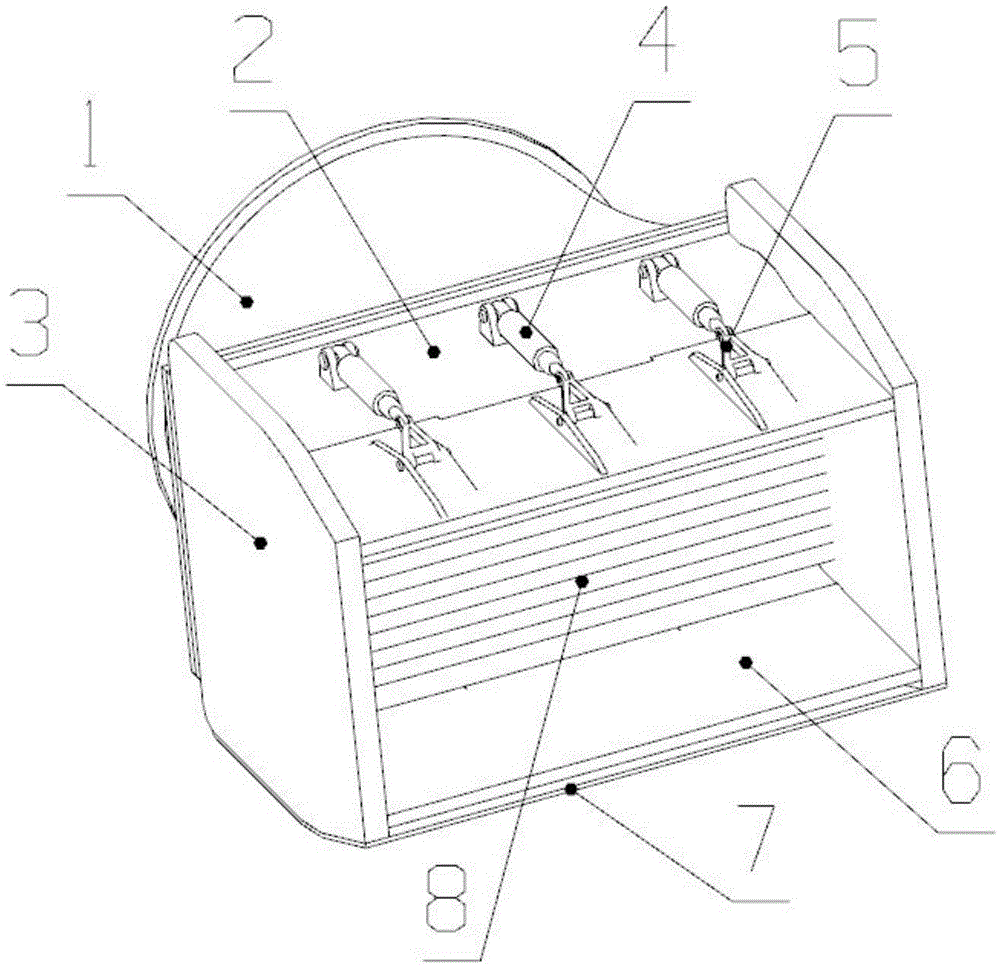

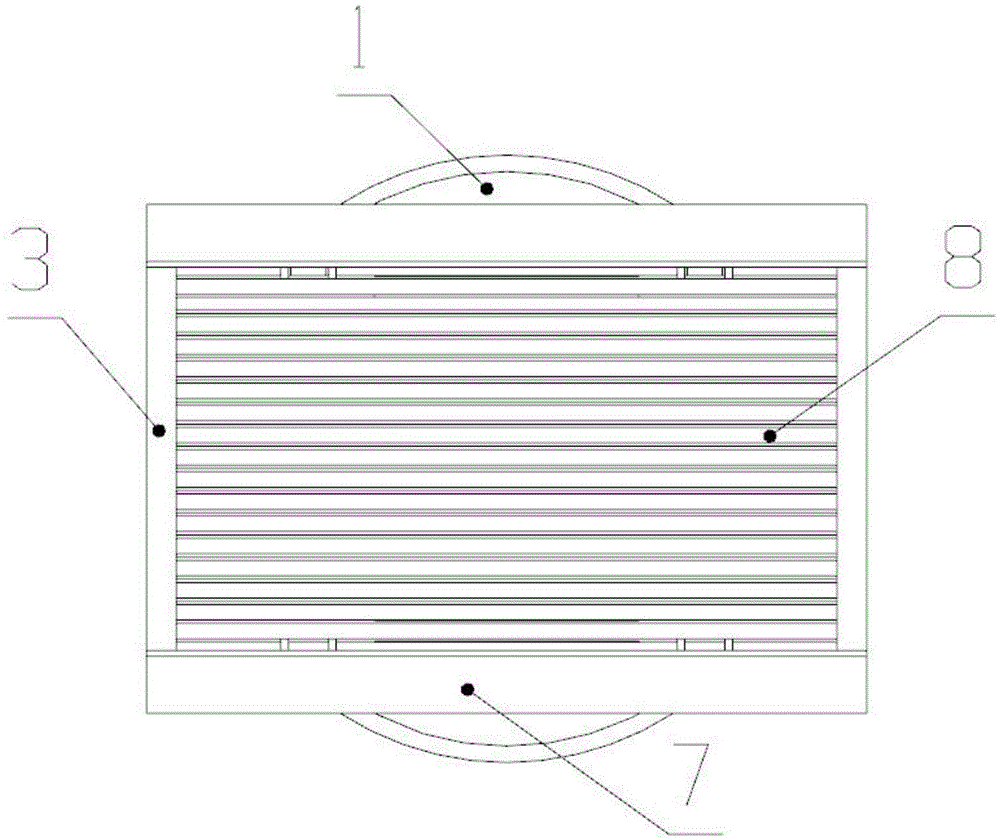

[0026] A new binary adjustable convergent nozzle mainly consists of a circular and square cylinder body 1, a convergence adjustment mechanism, a fixed flow channel plate 2, a side wall 3, a nozzle cover 7, and a shielding guide plate 8. Specifically:

[0027] The front end of the circular cylinder body 1 is connected with the engine as the supporting member of the whole nozzle.

[0028] The convergence adjustment mechanism is composed of an actuator 4, a link mechanism 5 and a convergence adjustment plate 6, wherein the actuator 4 is arranged along the axis of the convergence adjustment plate, and the front end is connected to the cylinder body 1 or the fixed flow channel plate through a mechanical connection. 2 On the outer wall, the rear end is connected to the link mechanism 5 through a rotating pair; the front end of the convergence adjustment plate 6 is connected to the fixed flow channel plate 2 through a rotating pair; It is connected with the middle section of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com