A New Axisymmetric Convergent Nozzle

An axisymmetric, nozzle technology, applied in the direction of jet propulsion, machine/engine, etc., can solve the problem of affecting the adjustment range of the nozzle throat, not being able to block the front hot end components, affecting the engine operating point, etc., to make up for the stealth function. Flaws, good stealth, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

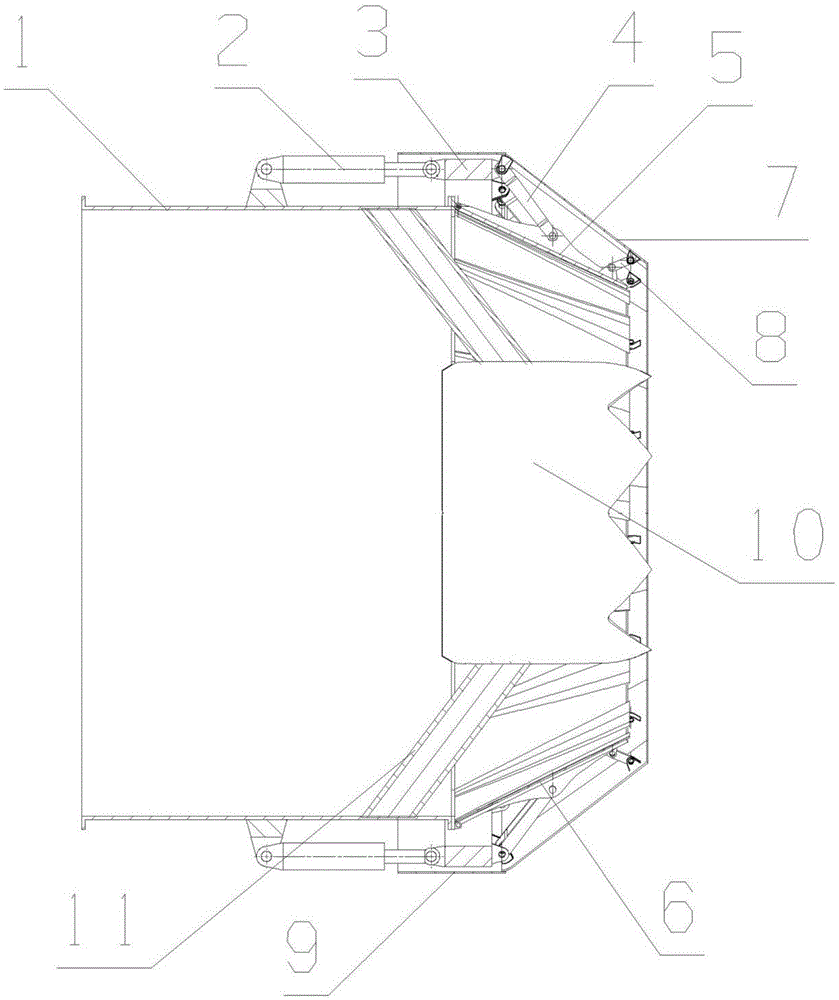

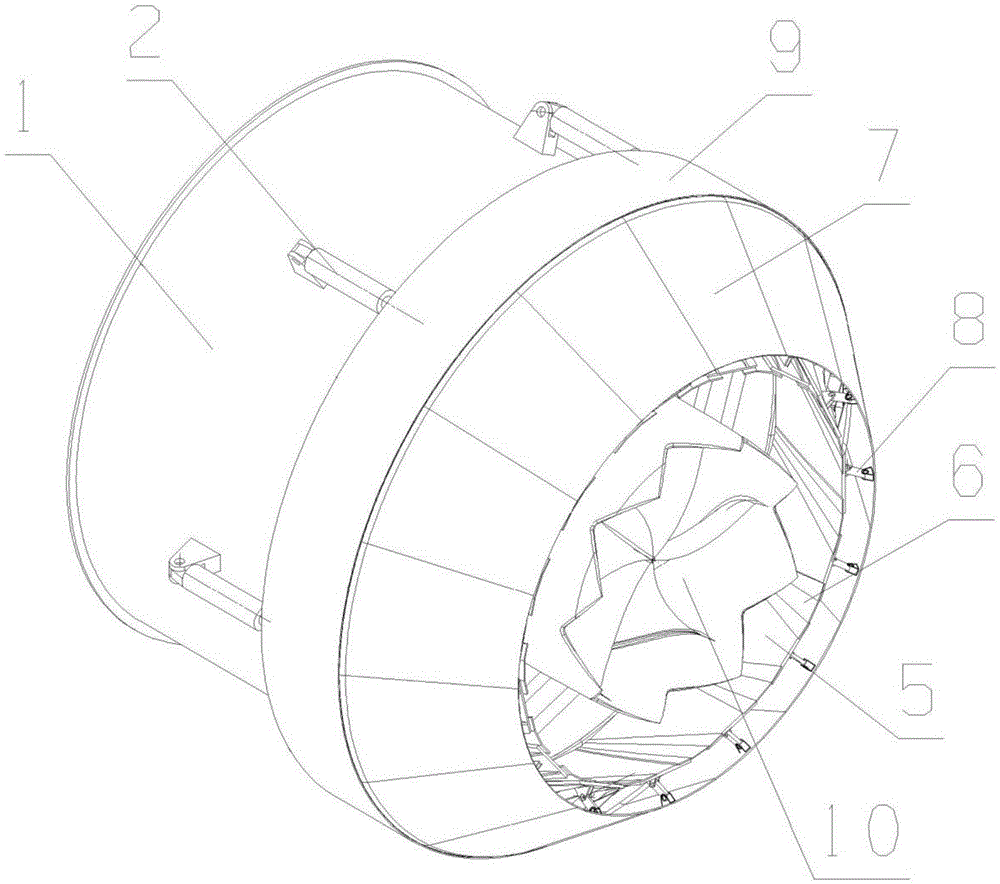

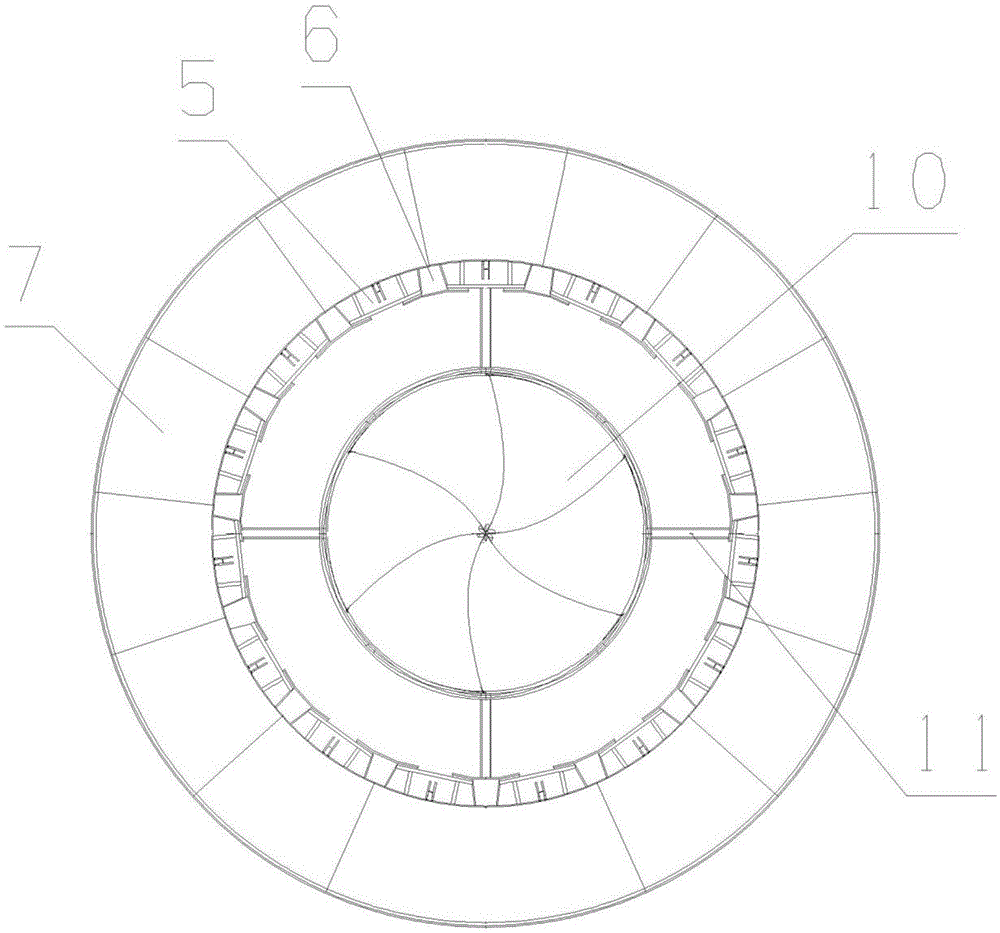

[0029] A new type of axisymmetric converging nozzle is mainly composed of a cylinder body 1, a drive adjustment mechanism, a sealing member, a central blocking member and an external rectifying member. Specifically:

[0030] The front end of the cylinder body 1 is connected with the engine as a supporting member for the entire nozzle.

[0031] The driving adjustment mechanism is mainly composed of an actuator 2, a synchronous adjustment ring 3, a pull rod 4 and a convergence adjustment piece 5. Wherein, the actuator cylinder 2 is arranged along the circumference of the nozzle, the front end is connected to the outer wall of the cylinder body 1 through a mechanical connection, and the rear end is connected to the synchronous adjustment ring 3; the rear end of the synchronous adjustment ring 3 is connected to the pull rod 4 through a rotating pair; The tie rod 4 is evenly distributed along the nozzle pipe circumference, and the other end is connected to the outer middle section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com