Axisymmetric vectoring nozzle with good stealth function

A vector nozzle, axisymmetric technology, which is applied to jet propulsion devices, machines/engines, etc., can solve the problems of not being able to block the front hot end components, affecting the adjustment range of the nozzle throat, and increasing the outline structure of the nozzle. Achieve the effect of making up for the defect of stealth function, good stealth ability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

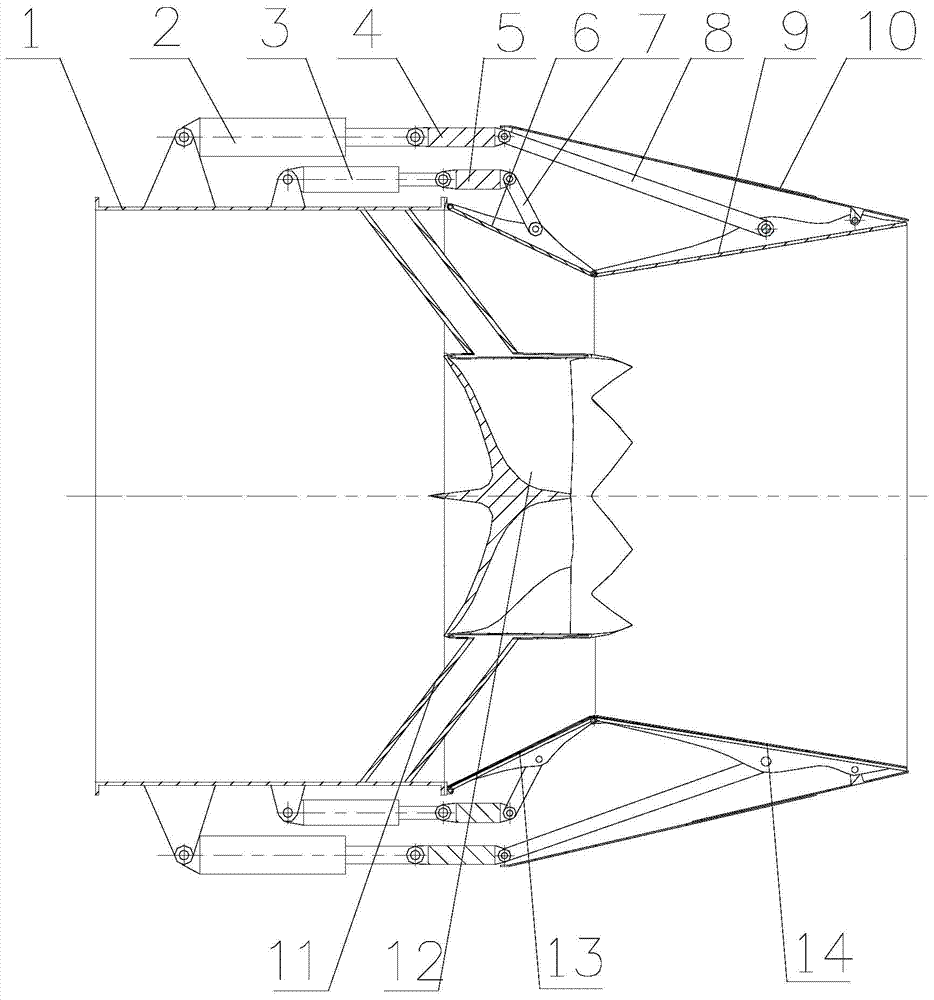

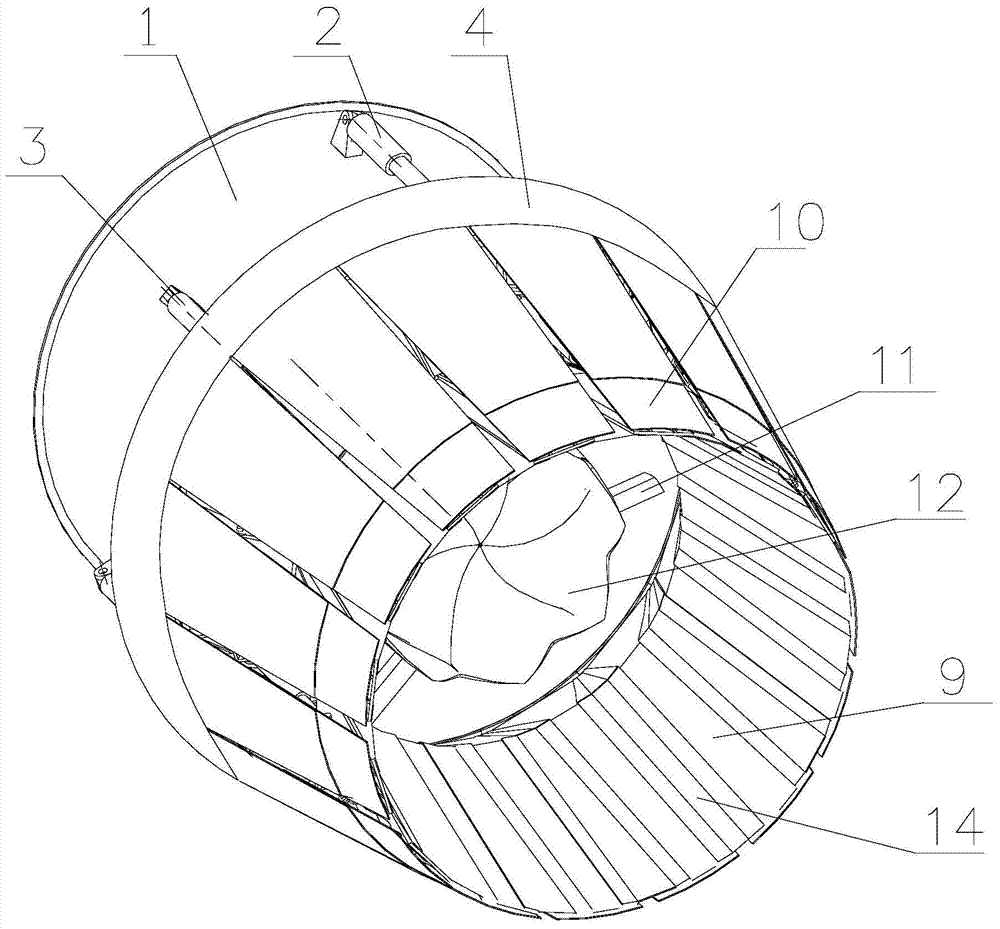

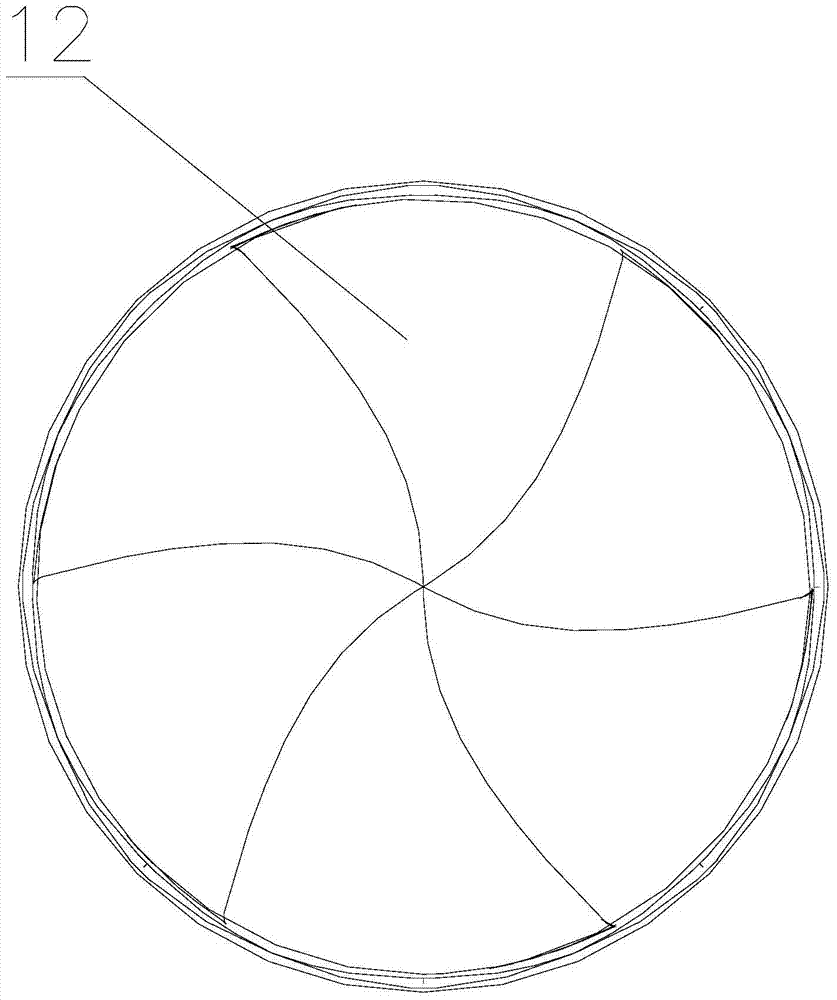

[0035] The invention provides an axisymmetric vector nozzle with good stealth function, which is characterized in that it is composed of a cylinder body 1, an expansion section adjustment mechanism, a throat adjustment mechanism, a sealing member, a central shielding member and an outer cover member; specifically:

[0036] The front end of cylinder body 1 is connected with the engine as a supporting member of the entire nozzle; the expansion section adjustment mechanism is mainly composed of vector actuator 2, vector adjustment ring 4, pull rod 8, and expansion adjustment piece 9; wherein, vector actuator 2 Arranged along the circumferential direction of the nozzle, the front end is connected to the outer wall of the barrel 1 through a mechanical connection, and the rear end is connected to the vector adjustment ring 4; The body 1 is connected to ensure the radial displacement of the vector adjusting ring 4 is limited; the tie rod 8 is evenly distributed along the circumference...

Embodiment 2

[0057] The invention provides an axisymmetric vector nozzle with good stealth function, which is characterized in that it is composed of a cylinder body 1, an expansion section adjustment mechanism, a throat adjustment mechanism, a sealing member, a central shielding member and an outer cover member; specifically:

[0058] The front end of cylinder body 1 is connected with the engine as a supporting member of the entire nozzle; the expansion section adjustment mechanism is mainly composed of vector actuator 2, vector adjustment ring 4, pull rod 8, and expansion adjustment piece 9; wherein, vector actuator 2 Arranged along the circumferential direction of the nozzle, the front end is connected to the outer wall of the barrel 1 through a mechanical connection, and the rear end is connected to the vector adjustment ring 4; The body 1 is connected to ensure the radial displacement of the vector adjusting ring 4 is limited; the tie rod 8 is evenly distributed along the circumference...

Embodiment 3

[0079] The invention provides an axisymmetric vector nozzle with good stealth function, which is characterized in that it is composed of a cylinder body 1, an expansion section adjustment mechanism, a throat adjustment mechanism, a sealing member, a central shielding member and an outer cover member; specifically:

[0080] The front end of cylinder body 1 is connected with the engine as a supporting member of the entire nozzle; the expansion section adjustment mechanism is mainly composed of vector actuator 2, vector adjustment ring 4, pull rod 8, and expansion adjustment piece 9; wherein, vector actuator 2 Arranged along the circumferential direction of the nozzle, the front end is connected to the outer wall of the barrel 1 through a mechanical connection, and the rear end is connected to the vector adjustment ring 4; The body 1 is connected to ensure the radial displacement of the vector adjusting ring 4 is limited; the tie rod 8 is evenly distributed along the circumference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com