Patents

Literature

61results about How to "Surface integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

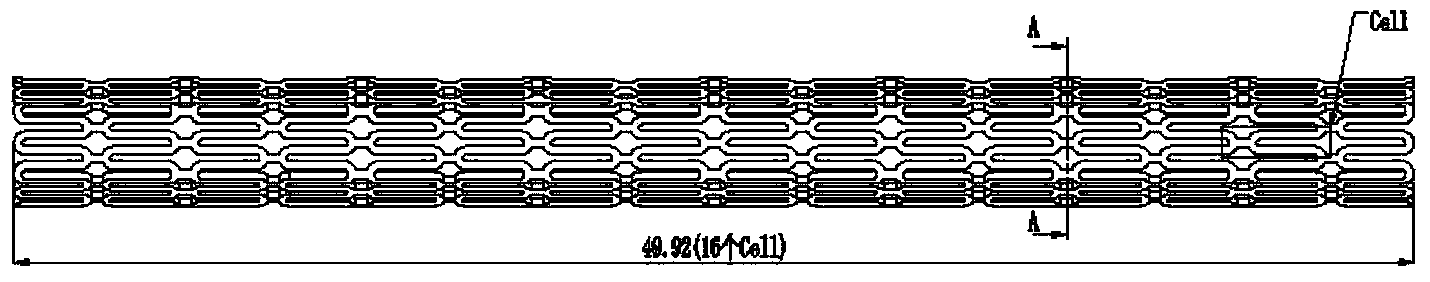

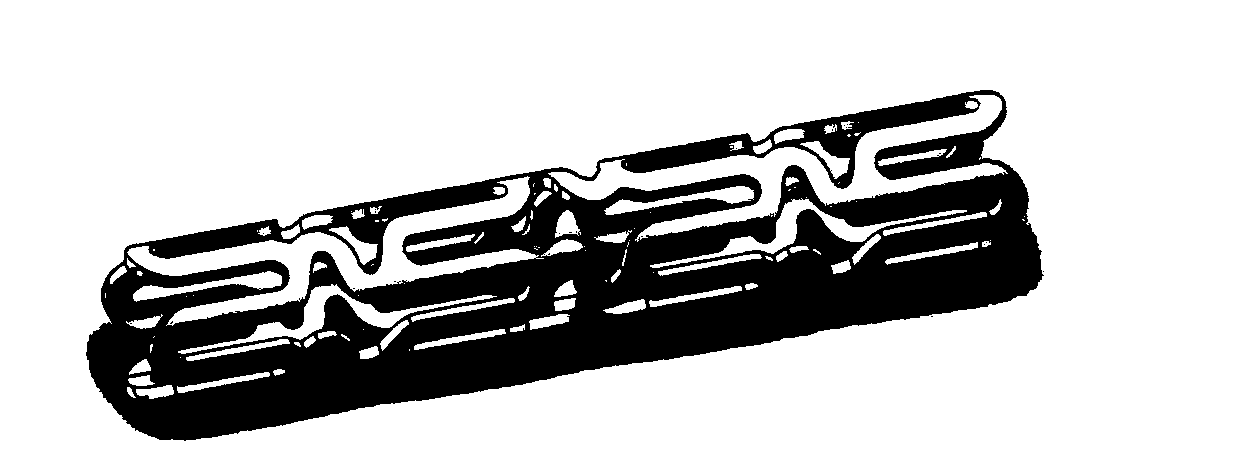

Method for preparing intravascular stent upon 3D (three-dimensional) printing technology

The invention discloses a method for preparing an intravascular stent upon the 3D (three-dimensional) printing technology. The method comprises the following steps: firstly establishing a 3D model of the intravascular stent in a computer; inputting data of the established model into corollary equipment of a 3D printer and setting a printing program; bonding a mixed powder material, consisting of stainless steel powder or nickel-titanium powder and stearic acid powder, with a bonder through 3D printing program control to form an intravascular stent blank; performing degreasing, vacuum sintering and cooling treatment on the blank in sequence to obtain the intravascular stent. According to the preparation method, the personalized model can be designed according to the actual requirement of a patient, and the required intravascular stent blank can be rapidly and accurately prepared; the further prepared intravascular stent has a complete surface and has no defects of deformation or cracking and the like; especially, the prepared intravascular stent has no rejection reaction in 24 days in simulated body fluid, is good in biocompatibility and completely meets the medical requirement; the cost for preparing the intravascular stent by a traditional laser cutting method is greatly reduced.

Owner:HUNAN HANDLIKE MINIMALLY INVASIVE SURGERY CO LTD

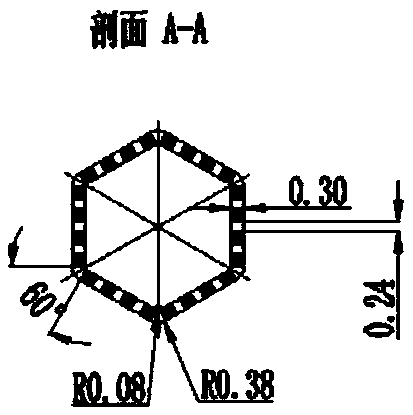

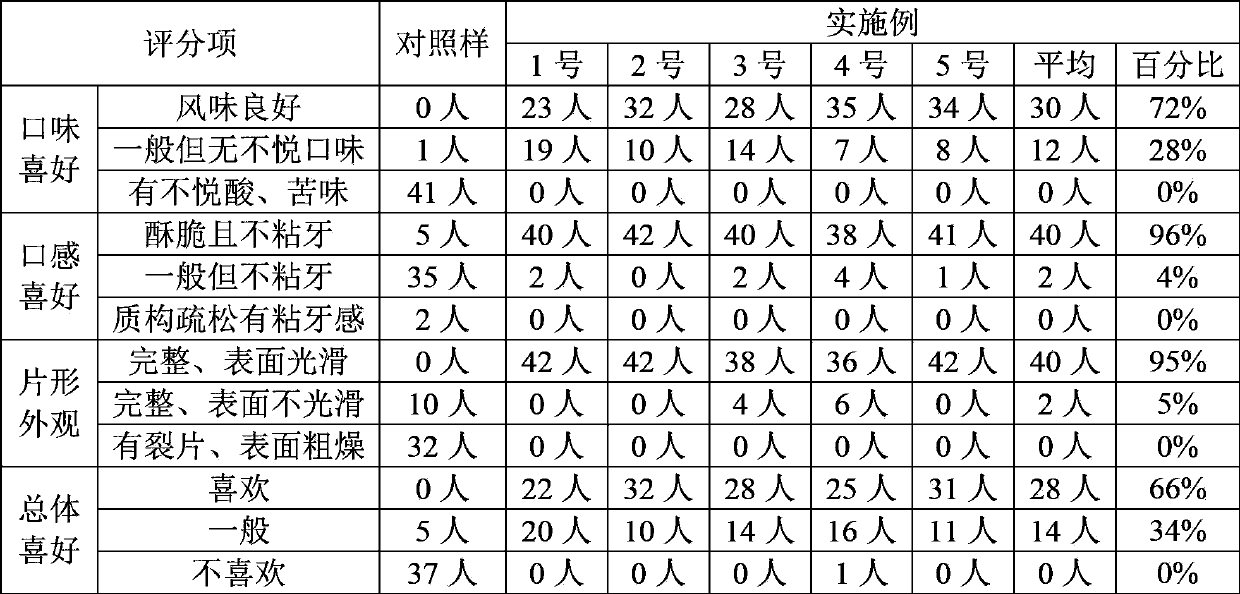

A compound fish scale peptide and calcium compound chewable tablet for antioxidation and calcium supplementing and a preparation method thereof

InactiveCN103202419ASolve the technical defects of low processing utilization rate and serious waste of resourcesEasy to eatFood shapingFood preparationSucroseMagnesium stearate

The invention belongs to the technical field of food processing, and in particular relates to a compound fish scale peptide and calcium compound chewable tablet for antioxidation and calcium supplementing and a preparation method thereof. The preparation method comprises the following steps: cleaning fish scales and stoving; pulverizing the dry fish scales; adding distilled water and alkaline protease to the pulverized fish scale powder for hydrolysis, heating for enzyme inactivation after the hydrolysis, filtering, concentrating and drying the filtrate to obtain fish scale antioxidant peptides, and collecting residue; and adding an aqueous citric acid solution to the residue, extracting, standing and filtering, recovering the resulting precipitate, and pulverizing to obtain fish scale calcium citrate. The products of the fish scale peptide and calcium compound chewable tablet of the invention is prepared by mixing fish scale antioxidant peptides, fish scale calcium citrate, whole milk powder, compressible starch, glucose, sucrose, citric acid, malic acid, food flavor, magnesium stearate, etc., crushing and sieving and tabletting forming. According to the present invention, the peptide extraction rate is 72.3-85.9% scale, and the calcium recycling rate is 67-78%. The preparation method of the invention is simple and practical, and the product of the invention has good taste and stability.

Owner:HUAZHONG AGRI UNIV

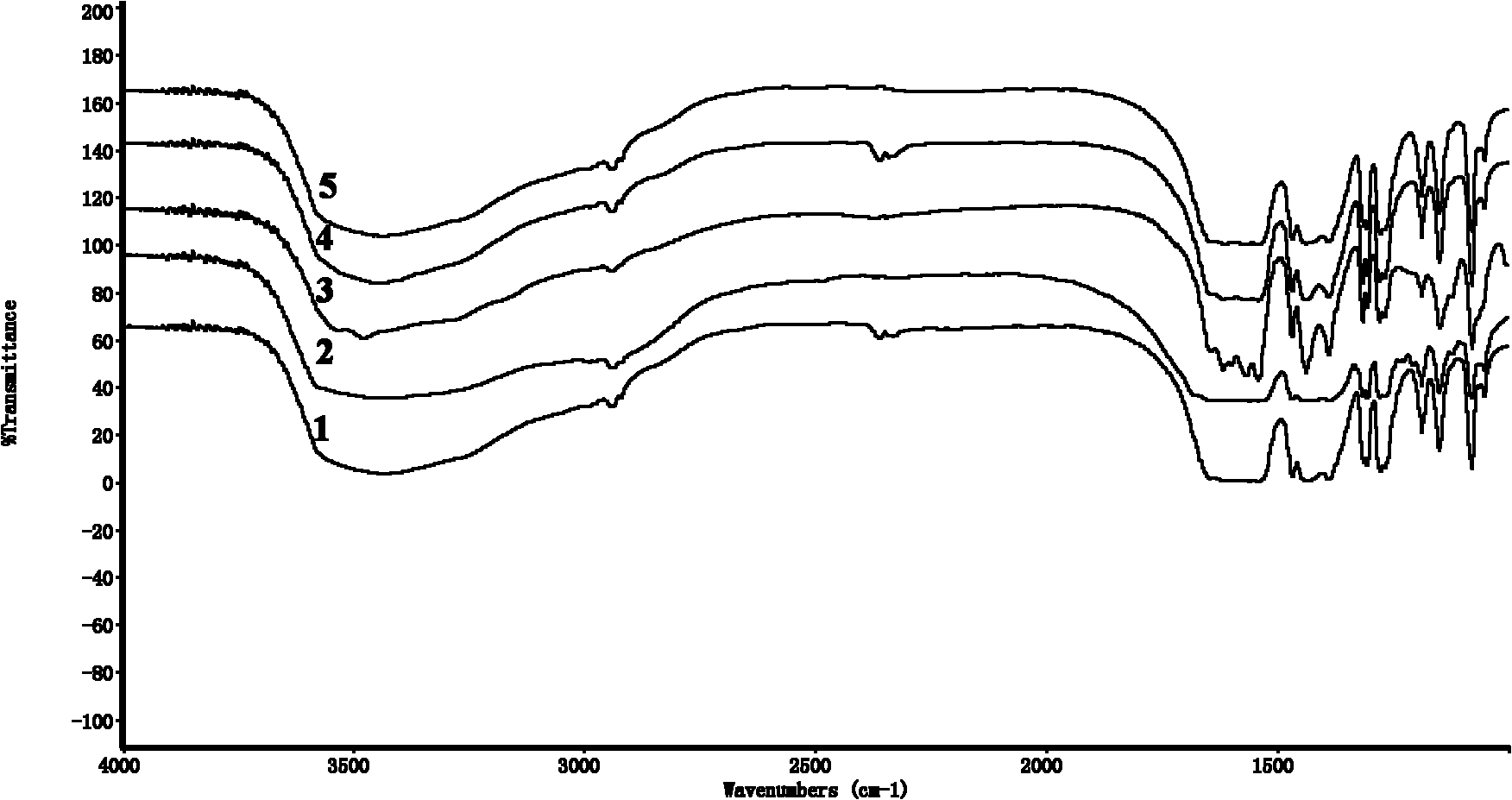

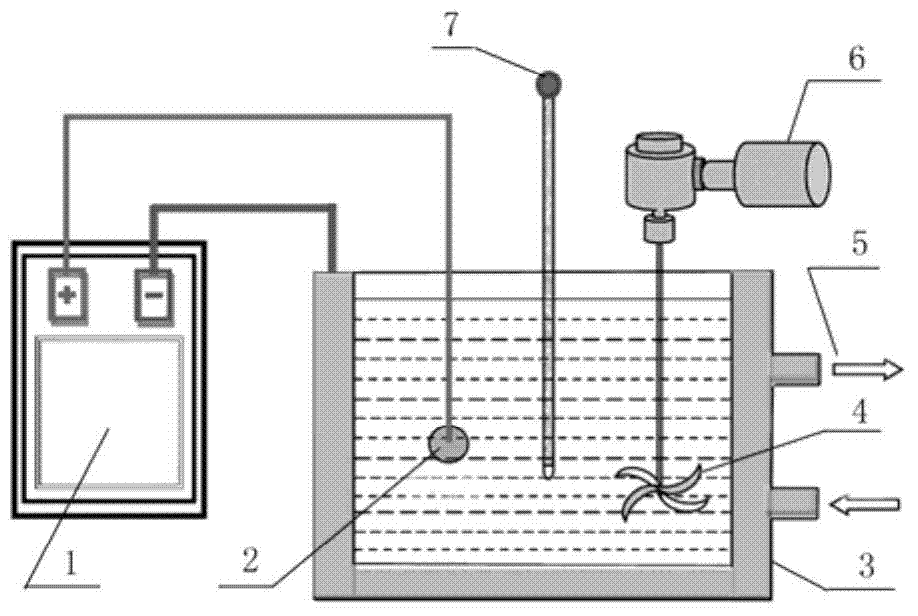

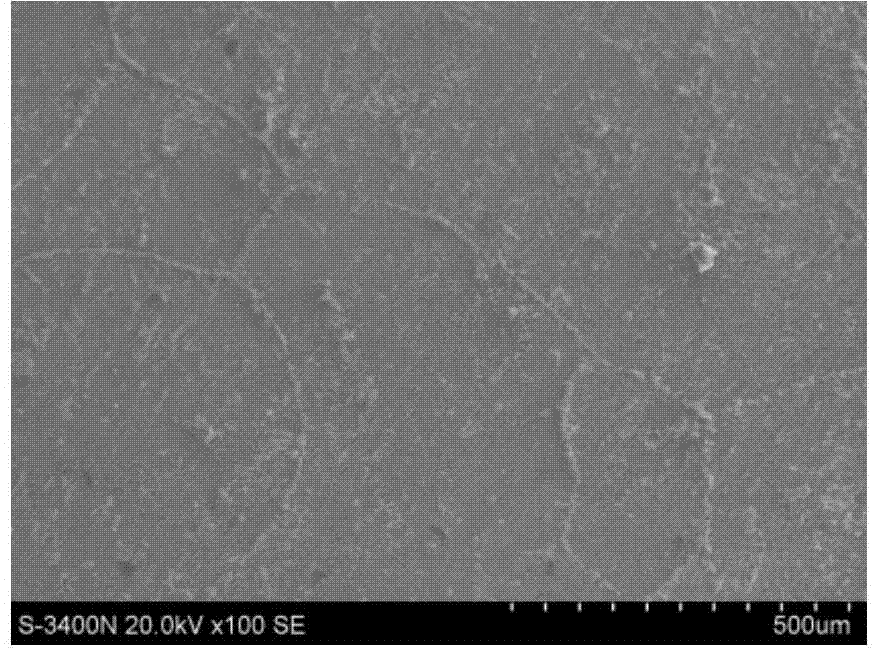

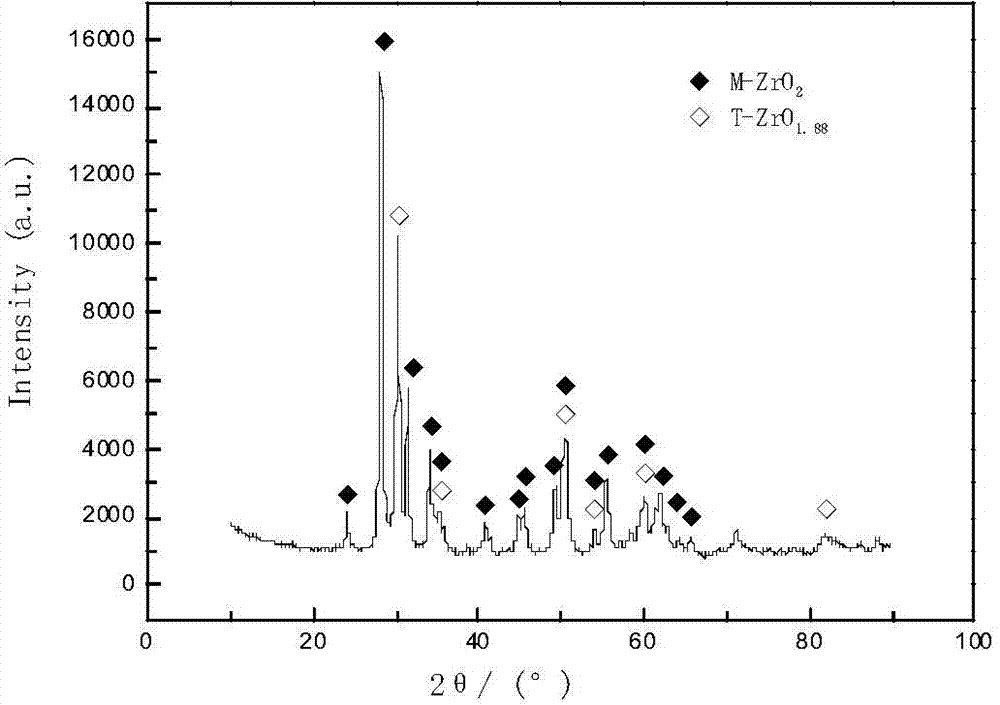

Preparation method for hydrogen-resistant coating on surface of zirconium hydride

ActiveCN103484917AContinuous surfaceSurface integrityNuclear energy generationSurface reaction electrolytic coatingZirconium hydrideElectrolytic agent

The invention relates to a preparation method for a hydrogen-resistant coating on the surface of zirconium hydride. The method is characterized in that a micro-arc oxidation and chemical solution precipitation and hole sealing combined technology is adopted for the preparation of a continuous and compact hydrogen-resistant coating on the surface of the zirconium hydride. According to the invention, a phosphate electrolyte system is adopted, and a zirconia ceramic layer is prepared on the surface of the zirconium hydride through micro-arc oxidation firstly, then a chemical solution method is adopted for hole sealing, and finally, a perfectly repaired zirconia hydrogen-resistant coating is prepared on the surface of the zirconium hydride. By utilizing the preparing method, the zirconia ceramic layer with the continuous and integral surface and the thickness bigger than 50 mum is prepared on the surface of the zirconium hydride; the zirconia ceramic layer is remarkable in hydrogen-resistant effect and better in high-temperature oxidation resistance.

Owner:INNER MONGOLIA UNIV OF TECH

Method for preparing personalized degradable metal stent or internal fixation device based on 3D printing

InactiveCN108113786AImprove processing efficiencyReduce manufacturing costStentsAdditive manufacturing apparatusWaxSize parameter

The invention discloses a method for preparing a personalized degradable metal stent or an internal fixation device based on 3D printing. The method comprises the following steps: (1) obtaining data of corresponding size parameters of a lesion in a human body through a QCA technology, and obtaining a structure of a blood vessel stent, other metal stents or the internal fixation device by three-dimensional reconstruction; (2) establishing a 3D model of a wax mold prototype of the blood vessel stent, other metal stents or the internal fixation device, and decomposing the 3D model into a series of 2D sheet models; (3) using a 3D printing technology to make the wax mold prototype; (4) leading gypsum into the wax mold prototype for shaping; after the gypsum is hardened, baking the gypsum to completely vaporize and evaporate the wax mold prototype, and then casting alloy melt; and after the casting is completed, breaking a shell to obtain the metal stent or the internal fixation device. According to the method, personalized customization can be performed according to a patient's diseased blood vessel, and the obtained metal stent or the internal fixation device is degradable, high in precision and good in mechanical properties and corrosion performance.

Owner:JINAN UNIVERSITY

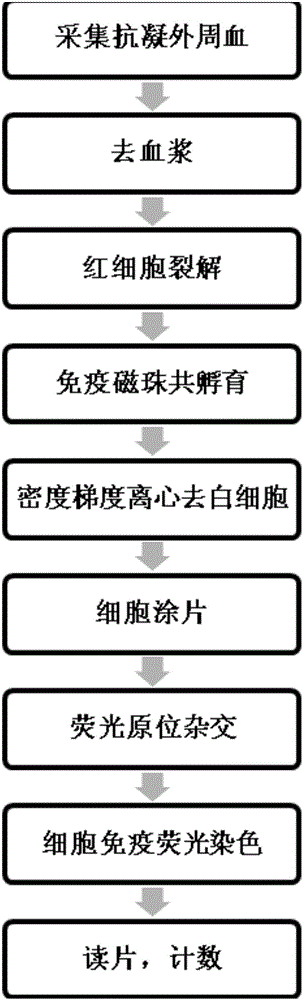

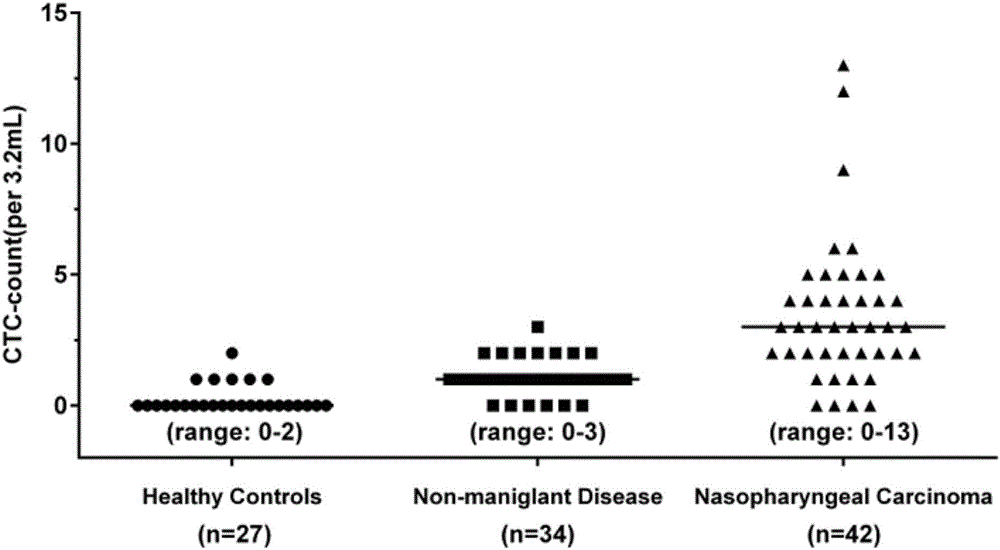

Detection kit for NPC (nasopharyngeal carcinoma) CTCs (circulating tumor cells)

InactiveCN106771185AHigh activityHigh fluorescence brightnessDisease diagnosisSodium bicarbonateBiotin-streptavidin complex

The invention provides a detection kit for NPC (nasopharyngeal carcinoma) CTCs (circulating tumor cells). The detection kit comprises a human peripheral blood leucocyte removal part and an immunofluorescence in-situ hybridization identification part, wherein the human peripheral blood leucocyte removal part comprises a dilution buffer, a red blood cell lysis buffer, a density gradient centrifugation medium, a cell immobilization liquid A and immunomagnetic beads, and the red blood cell lysis buffer is formed by mixing ammonium chloride, sodium bicarbonate and an EDTA-2Na solution; the immunofluorescence in-situ hybridization identification part comprises a buffer, a hybridization stationary liquid B, a biotin labeled CEP8 probe, a red quantum dot labeled CD45 antibody, green quantum dot labeled streptavidin, a mounting medium and bovine serum albumin powder. The detection kit combines an immunomagnetic enrichment and separation technology, a fluorescence in-situ hybridization technology, an immunofluorescence cytochemical technology and an NPC CTC counting technology and can determine the number of the NPC CTCs in a sample precisely.

Owner:湖北省肿瘤医院

Soybean peptide chewable tablets and preparation method thereof

ActiveCN103859253AGood water solubilityStay nourishedSugar food ingredientsFood shapingAlcoholAdditive ingredient

The invention discloses soybean peptide chewable tablets and a preparation method thereof, and belongs to the field of functional food technology. The preparation method comprises the steps of preparing a main ingredient soybean peptide powder contained in the chewable tablets and various auxiliary materials contained in the chewable tablets according to a certain proportion, mixing, then directly tabletting, carrying out sterilization and package and other process steps, and thus obtaining the product. The soybean peptide chewable tablets are simple in preparation, keep the soybean peptide nutrition and active functions, have high soybean peptide content which is more than 48%, are good in taste and mouthfeel and good in product stability, have the functions of enhancing immunity, relieving fatigue, improving athletic ability, controlling weight, dispelling alcohol effects to protect liver and the like, are convenient to carry, and are fast absorbed by bodies.

Owner:COFCO NUTRITION & HEALTH RES INST +1

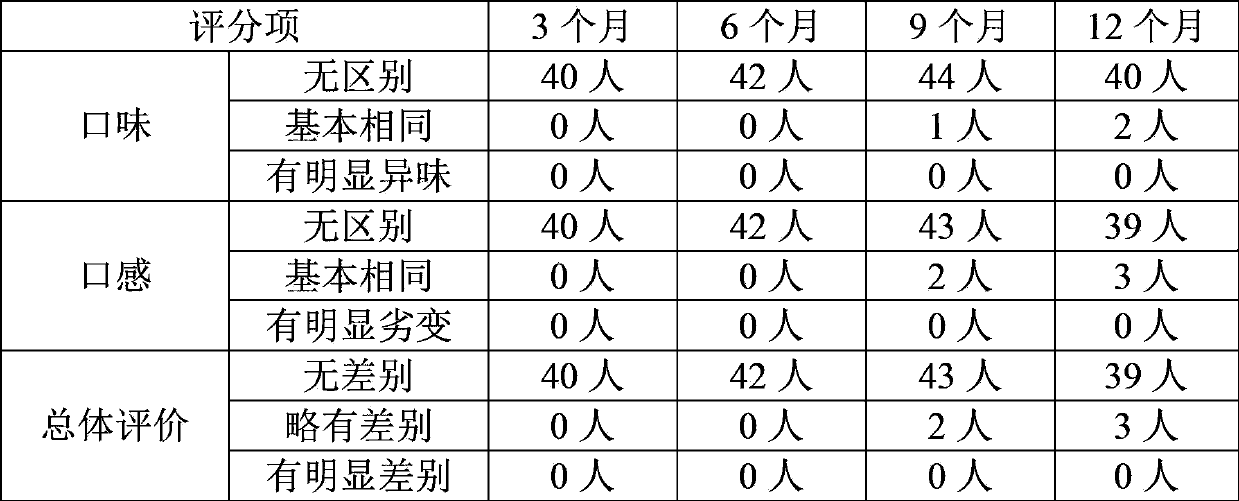

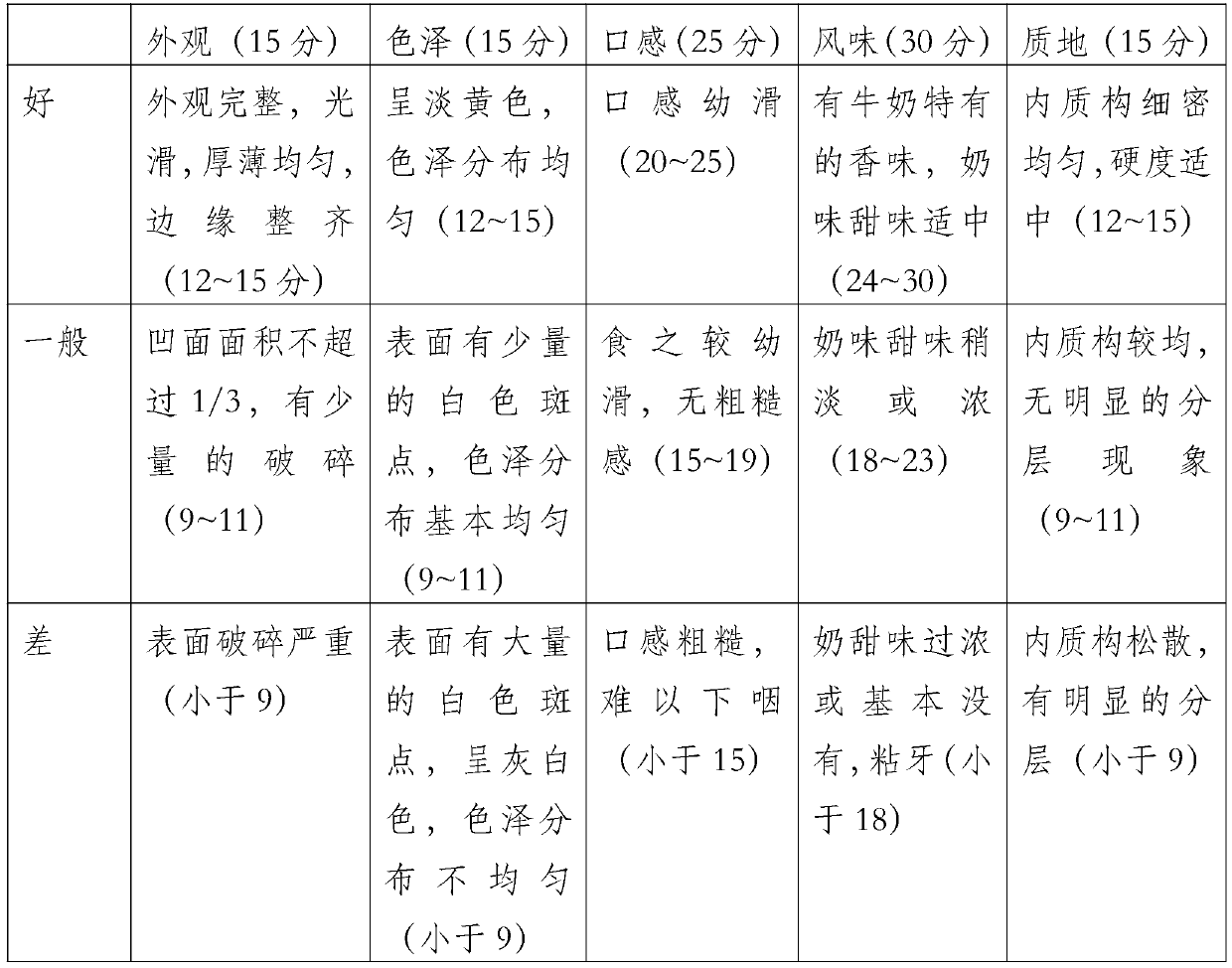

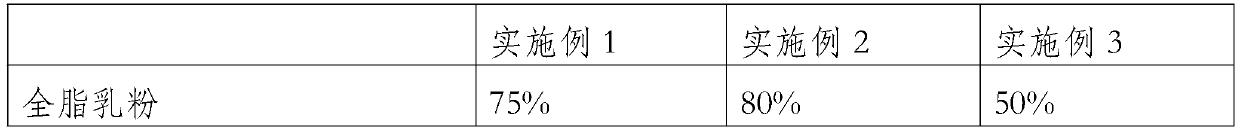

Nutritious chewable milk tablet added with DHA algae oil microcapsule powder and preparation method of nutritious chewable milk tablet

PendingCN110074191AFull of nutritionComplete shapeMilk preparationChemistrySodium carboxymethylcellulose

The invention discloses a nutritious chewable milk tablet added with DHA algae oil microcapsule powder and a preparation method of the nutritious chewable milk table. The nutritious chewable milk tablet is prepared from the following materials by mass percent: 50-80% of whole milk powder, 8-12% of edible glucose, 6-9% of maltitol, 4-10% of the DHA algae oil microcapsule powder, 1-2% of hawthorn powder, 1-2% of sea buckthorn powder, 0.4-1.2% of zinc gluconate, 4-6% of taurine, 0.1-0.5% of magnesium stearate, 0.2-0.4% of silicon dioxide and 0.5-0.8% of sodium carboxymethylcellulose. The nutritional chewing milk tablet prepared by the method is rich in nutrition and good in product stability, and has a better shelf life.

Owner:广东新乐食品有限公司

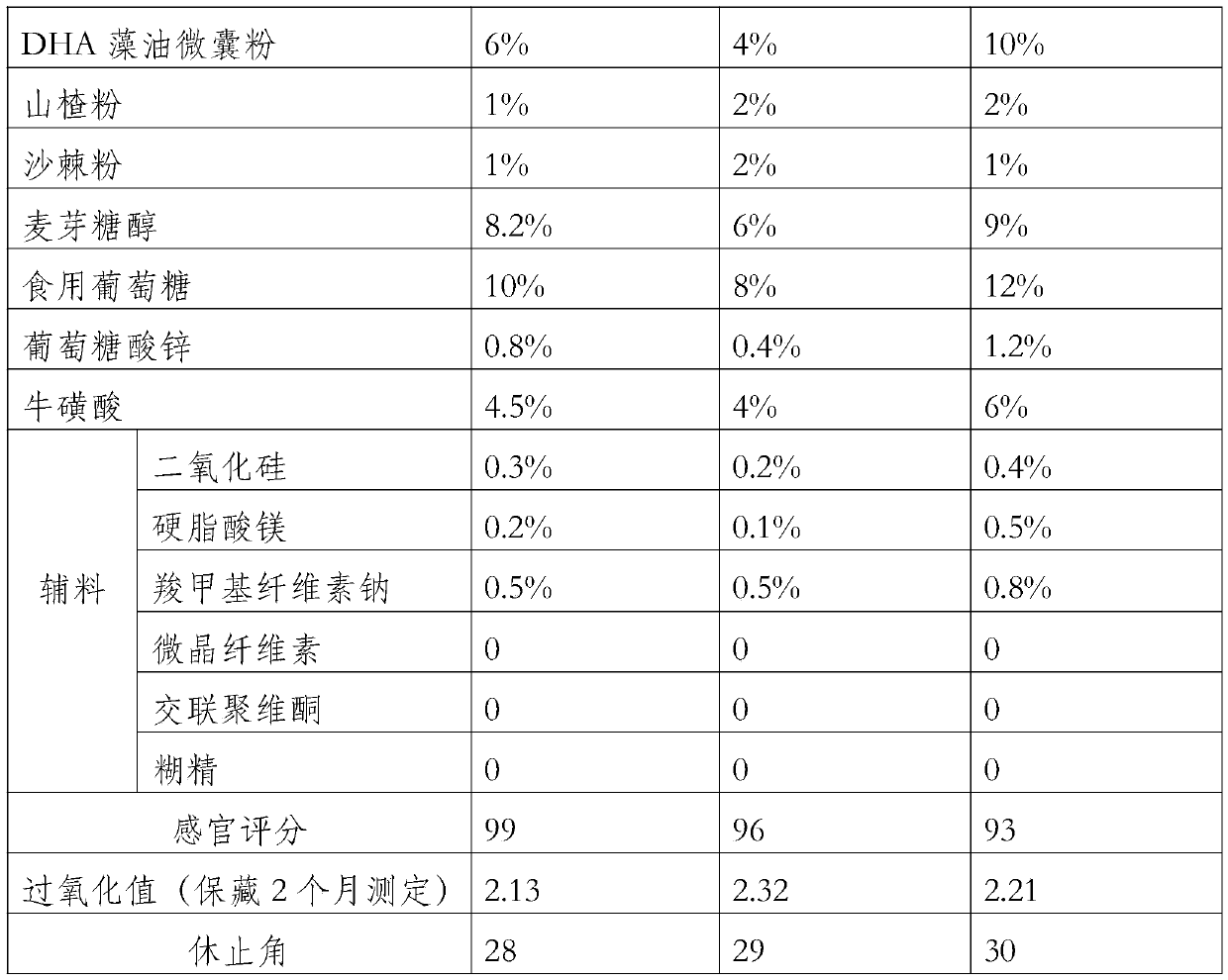

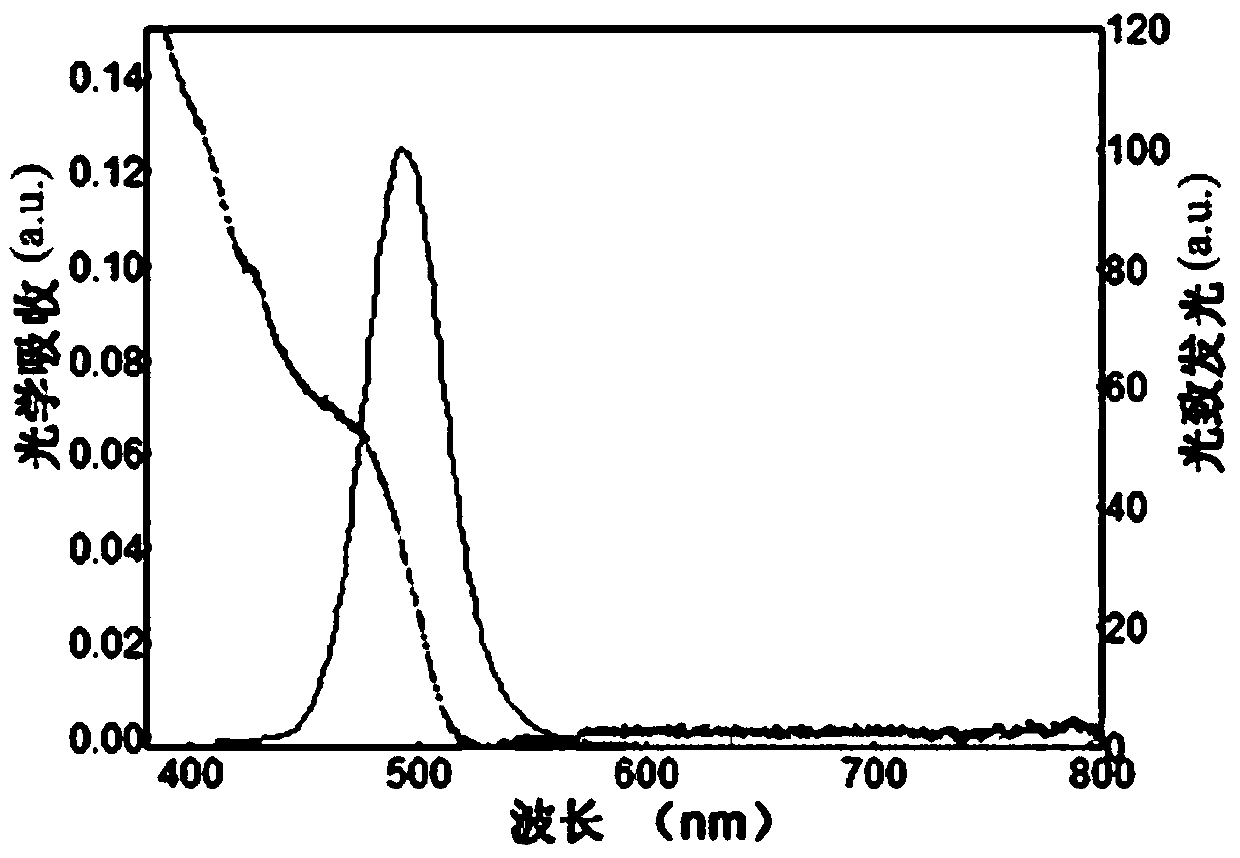

Method for preparing one-dimensional luminescent ultrafine CsPbBr3 perovskite nano-wires

ActiveCN108675341ASurface integrityReduce defectsNanotechnologyLead compoundsWater bathsQuantum yield

The invention relates to a method for preparing one-dimensional luminescent ultrafine CsPbBr3 perovskite nano-wires. The method comprises the following steps: mixing a surfactant A, a surfactant B anda solvent in water bath with a certain temperature, carrying out uniform stirring so as to obtain a settled solution, then, adding reactants, i.e., PbBr2 and CsBr, carrying out a reaction at a certain revolution rate, and carrying out centrifugal separation after the reaction ends up, thereby obtaining lower-layer precipitates, i.e., the CsPbBr3 perovskite nano-wires. According to the method, thediameter-controllable CsPbBr3 nano-wires with very high purity can be prepared in one step without later stage purification at room temperature without any gas protection. The nano-wires prepared bythe method have the advantages of relatively complete surface, few defects and the like, electrons and holes can be effectively and directly combined to emit light, excellent light emitting propertiesare shown, and the nano-wires have higher quantum yield and are hopefully applied to optical devices such as next-generation full-inorganic perovskite LED, optical detectors, lasers and the like.

Owner:SHANDONG UNIV

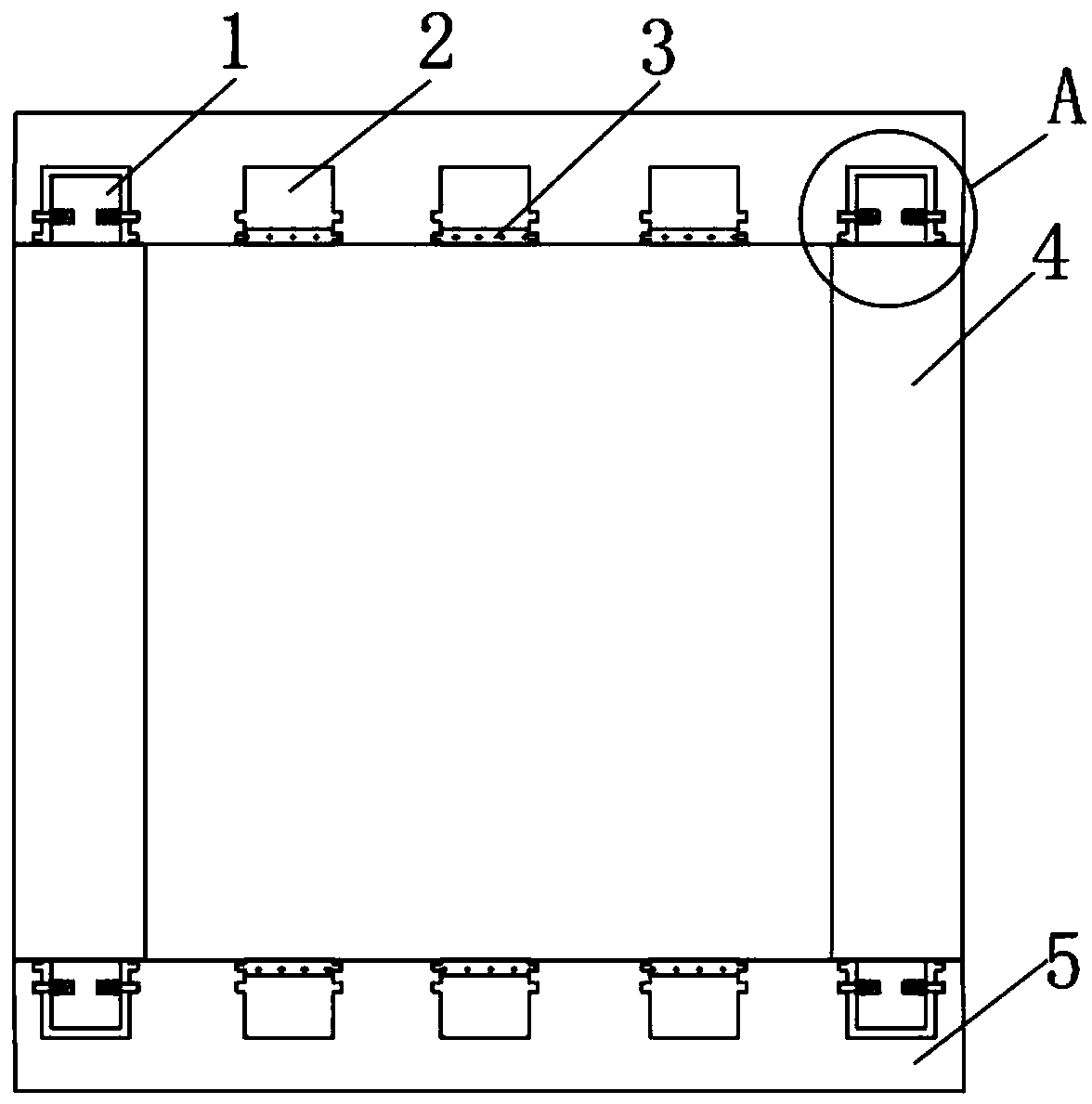

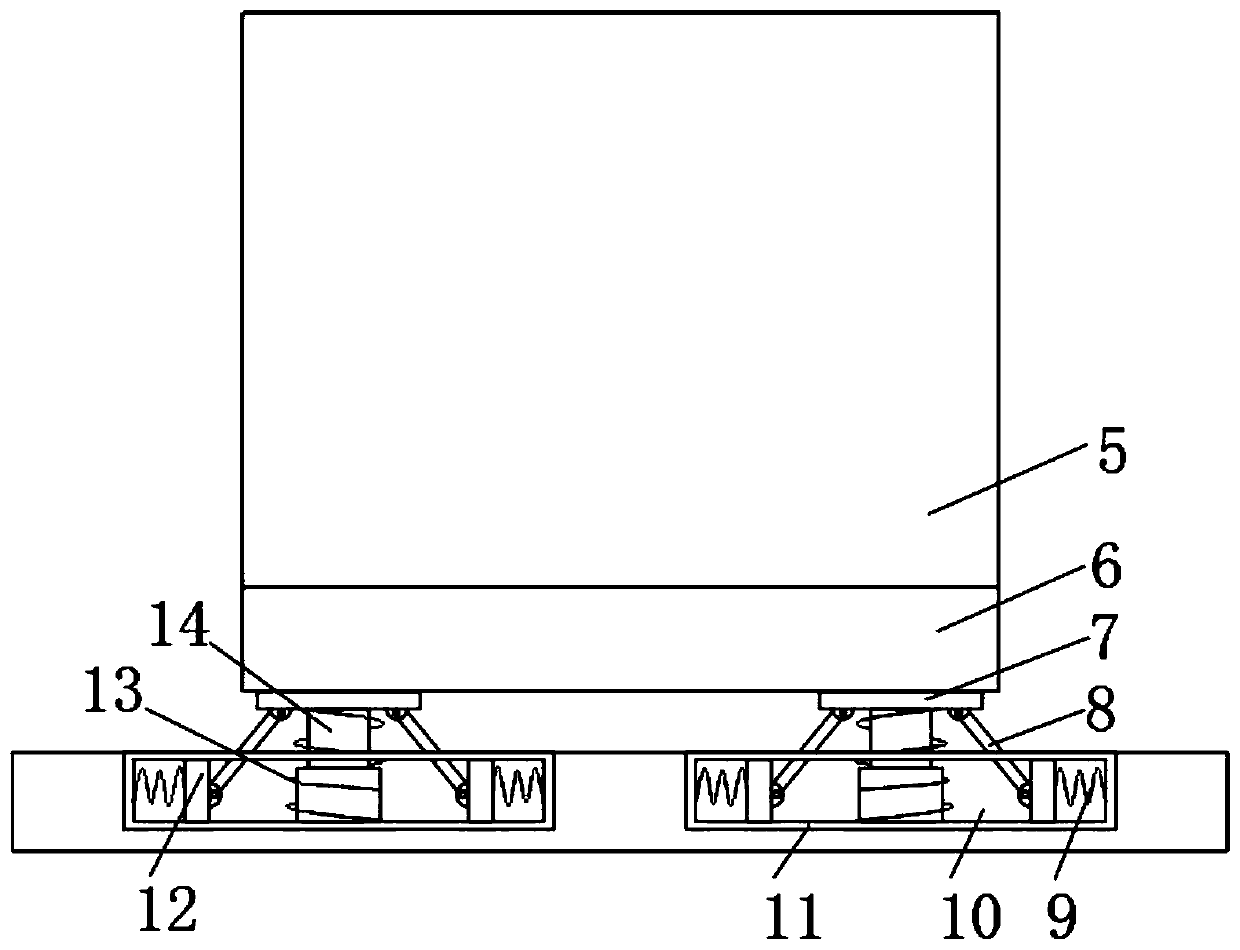

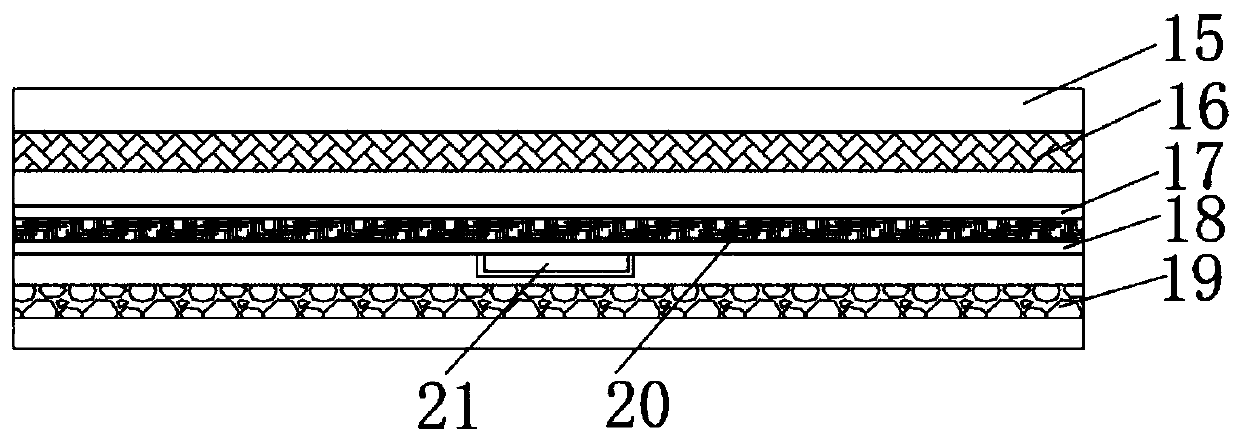

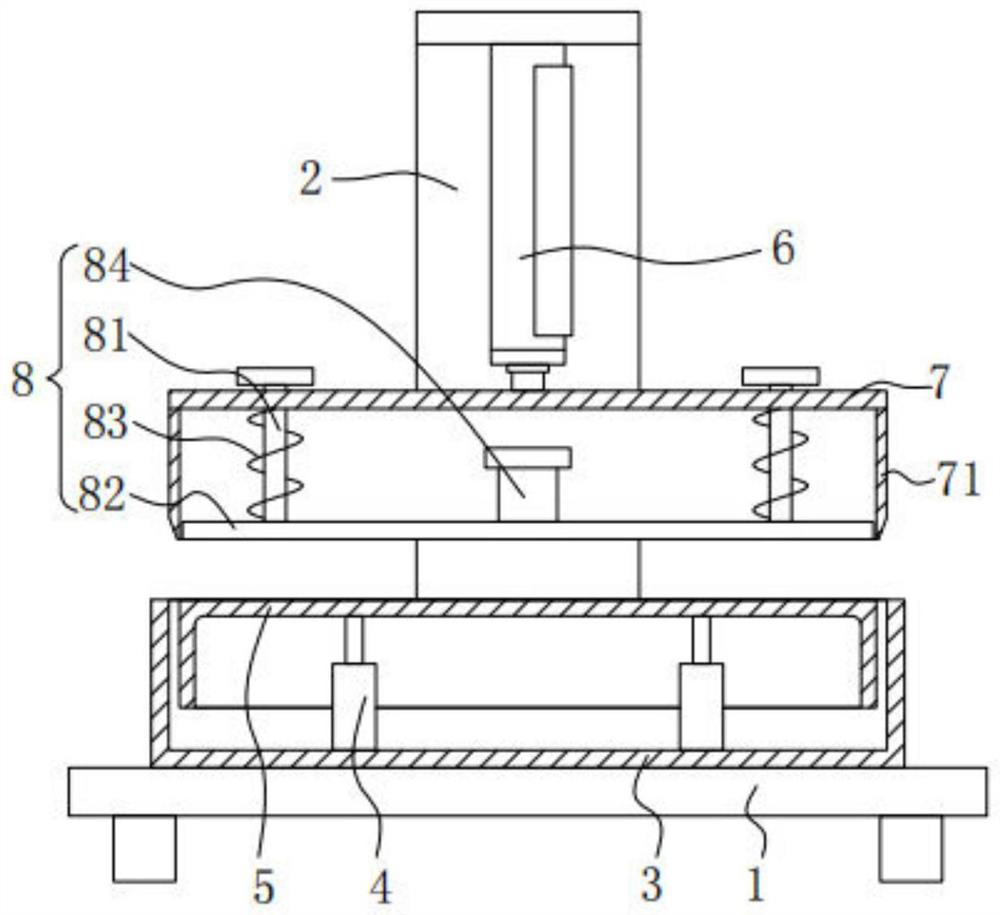

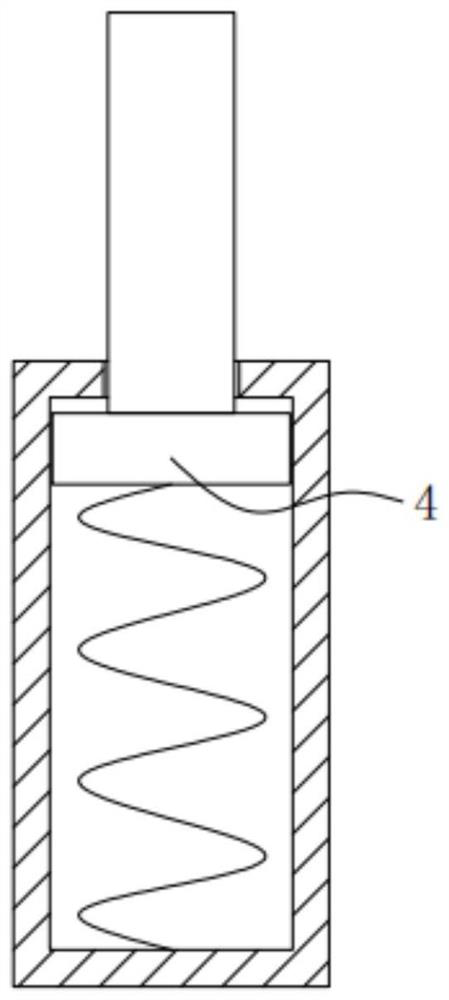

Fabricated building having space capable of being largened and applying cement prefabricated components

ActiveCN110512899ASurface integrityDoes not affect aestheticsWallsProtective buildings/sheltersResidenceArchitectural engineering

The invention discloses a fabricated building having a space capable of being largened and applying cement prefabricated components. The fabricated building comprises a first bottom plate; a pluralityof damping mechanisms are arranged at the lower end of the first bottom plate, and the upper end of the first bottom plate is fixedly connected with two transverse wall bodies; two longitudinal wallbodies are arranged between the two transverse wall bodies, and the two ends of the two longitudinal wall bodies are fixedly connected with limiting plates; the limiting plates are fixedly connected with the longitudinal wall bodies through limiting mechanisms, a plurality of limiting grooves are formed in the opposite side walls of the two transverse wall bodies correspondingly, and clamping grooves are formed in the opposite inner wallsof the limiting grooves correspondingly; partition plates are slidably connected into the clamping grooves, mounting cavities are formed in the first bottom plate, and telescopic mechanisms are arranged in the mounting cavities; two first device cavities are formed in the first bottom plate, and first baffles are slidably connected into the first device cavities; and the telescopic mechanisms are connected with the first baffles. The fabricated building is reasonable in structural design, the space of a residence can be changed to be largened, good safety performance is achieved, and the safety performance of the residence is improved.

Owner:江苏博拓新型建筑材料股份有限公司

Adhesive high temperature-resistant demoulding cloth and preparation method thereof

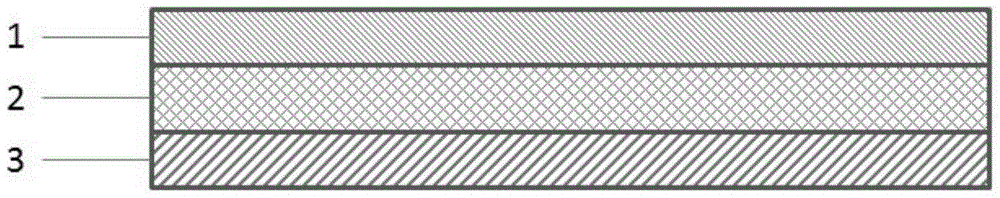

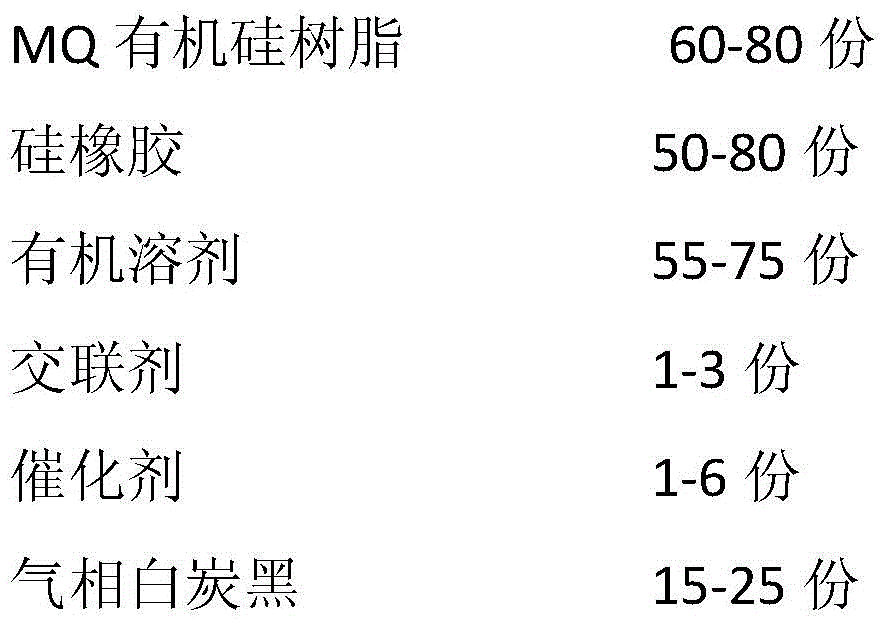

ActiveCN105667017AExcellent high temperature peel resistanceStrong self-adhesiveNon-macromolecular adhesive additivesSynthetic resin layered productsGlass fiberEngineering

The invention provides an adhesive high temperature-resistant demoulding cloth and a preparation method thereof, which belong to the technical field of the demoulding cloth. The demoulding cloth comprises an antistick layer, a bearing fabric layer and a bonding layer from up to down, the antistick layer is a teflon film, the bearing fabric layer is glass fiber cloth, and the bonding layer is an organosilicon pressure-sensitive adhesive. The invention also provides the preparation method of the adhesive high temperature-resistant demoulding cloth, the method is characterized in that the teflon film and a glass fiber cloth round roller are subjected to hot pressing for compositing to prepare the glass fiber-enhanced antistick layer; then the glass fiber surface is coated with a stock solution of the organosilicon pressure-sensitive adhesive, and then is slaked at the high temperature to obtain the adhesive high temperature-resistant demoulding cloth. According to the invention, the surface of the demoulding cloth is integral without pin holes, the demoulding can be carried out at the high temperature of 80 DEG C, a production period is shortened, and efficiency is increased.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

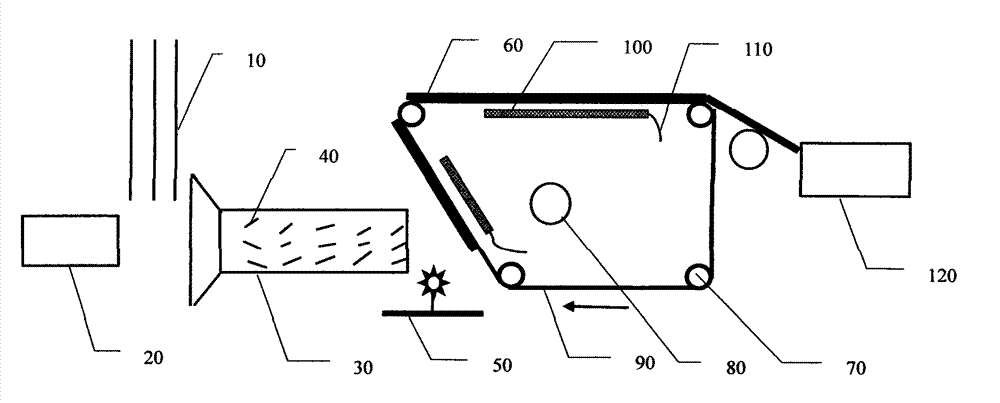

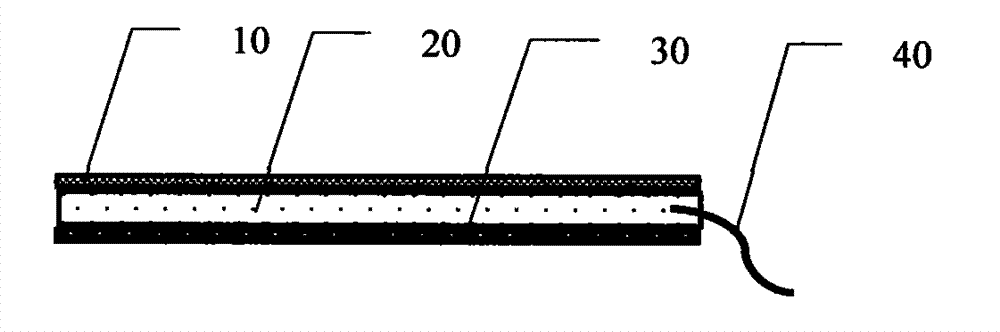

Self-heating cotton collection apparatus

ActiveCN104773953AShorten the timeStrong penetrating powerGlass making apparatusSolid phasesInfrared

The invention provides a self-heating cotton collection apparatus, comprising a cotton guiding chamber, a stainless steel mesh belt, a cotton collecting box, a negative pressure blower fan, an adhesive spraying pipe and an infrared radiation hot plate. The infrared radiation hot plate is installed in the cotton collection apparatus and comprises a thermal-isolation heat-preserving layer, a heatproof heat-preserving heating layer and a heat-conducting radiation layer, wherein the heating layer is a heating diode, and an infrared radiation paint is adhered on the heat-conducting radiation layer. The self-heating cotton collection apparatus employs infrared radiation heat transfer and utilizes the characteristics of strong penetrating force, high heating efficiency and the like of infrared rays to realize long-distance heat-curing of cotton silk; i.e., curing of the cotton silk is started before falling of the cotton silk on a stainless steel mesh, and the cotton silk and the stainless steel mesh contact in a solid phase manner after the cotton silk falls on the stainless steel mesh, thereby producing a good abhesion effect. Through curing of cotton felt in advance, the temperature of a curing furnace can be properly reduced, and time spent in a curing furnace can be effectively decreased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for matrix strengthening and surface coating of graphite guide cylinder for czochralski silicon single crystal

InactiveCN103046034APrevent intrusionHigh strengthBy pulling from meltSolid/suspension decomposition chemical coatingCarbide siliconSurface oxidation

The invention discloses a method for matrix strengthening and surface coating of a graphite guide cylinder for a czochralski silicon single crystal. The method comprises the following steps that (1) surface pretreatment is conducted; (2) hydrocarbon gas is adopted for chemical vapor deposition, and a matrix is strengthened; (3) silicon carbide powder, silicon powder and a solvent are mixed at a mass ratio of 1:(3-5):(6-8) and stirred uniformly; slurry is obtained; the surface of the graphite guide cylinder is uniformly coated with the slurry about 30-50 micrometers thick, and then the graphite guide cylinder is put into a curing furnace for baking treatment; (4) the graphite guide cylinder is placed in a high temperature furnace for in-situ reaction; an SiC outer layer is prepared; and (5) the graphite guide cylinder is placed in a chemical vapor deposition furnace, and the hydrocarbon gas is adopted for the chemical vapor deposition. With the method, the strength of the graphite guide cylinder can be effectively improved in a high temperature use process, and the problems that the existing graphite guide cylinder has external surface oxidization, overall cracking, chipping, and the like after short-term use can be effectively solved.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

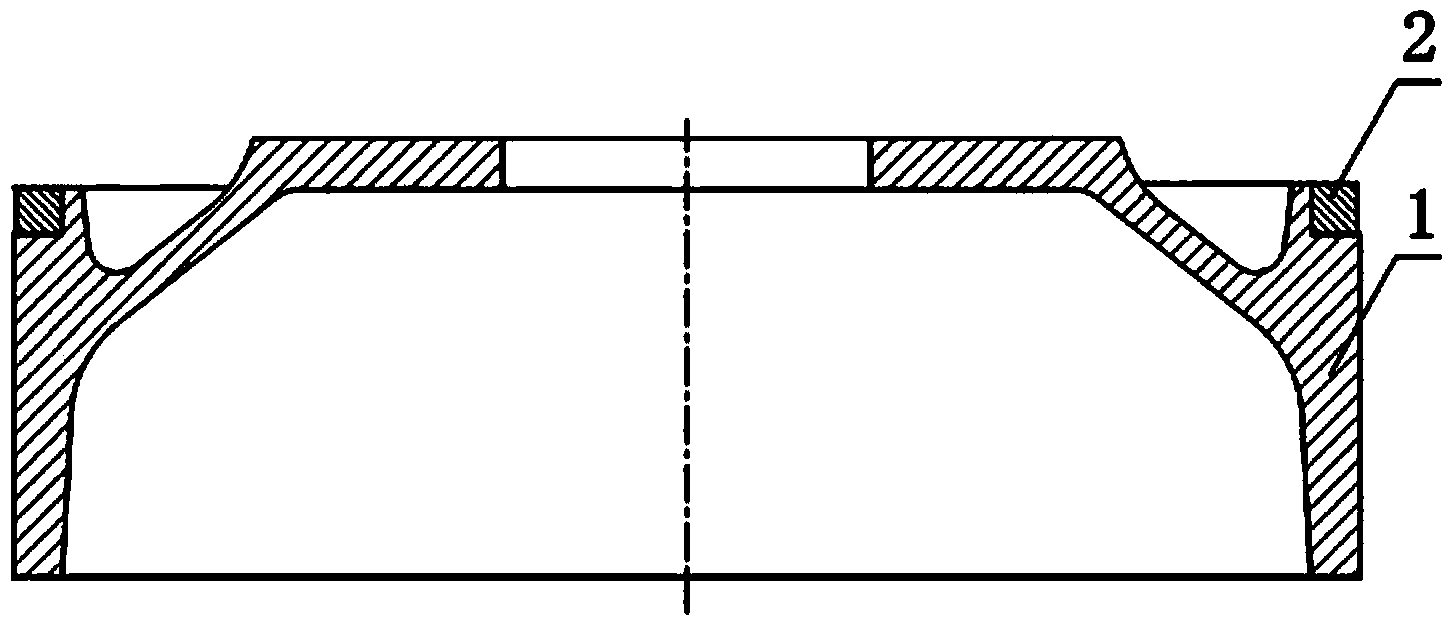

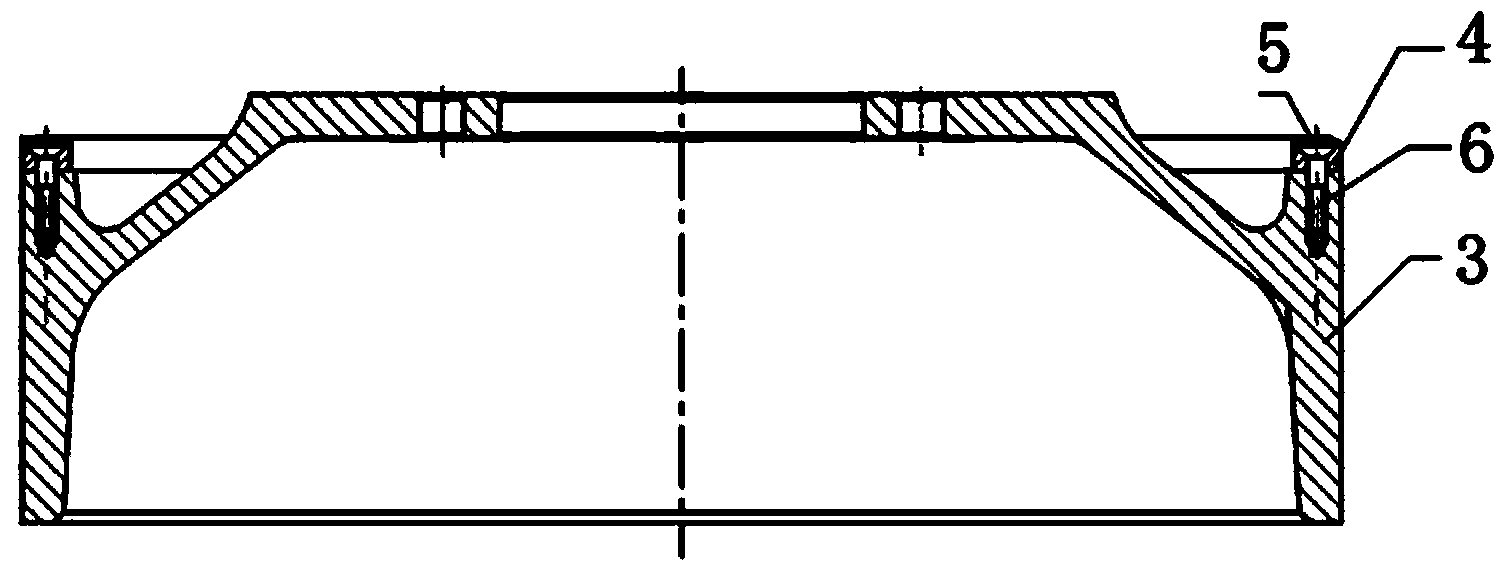

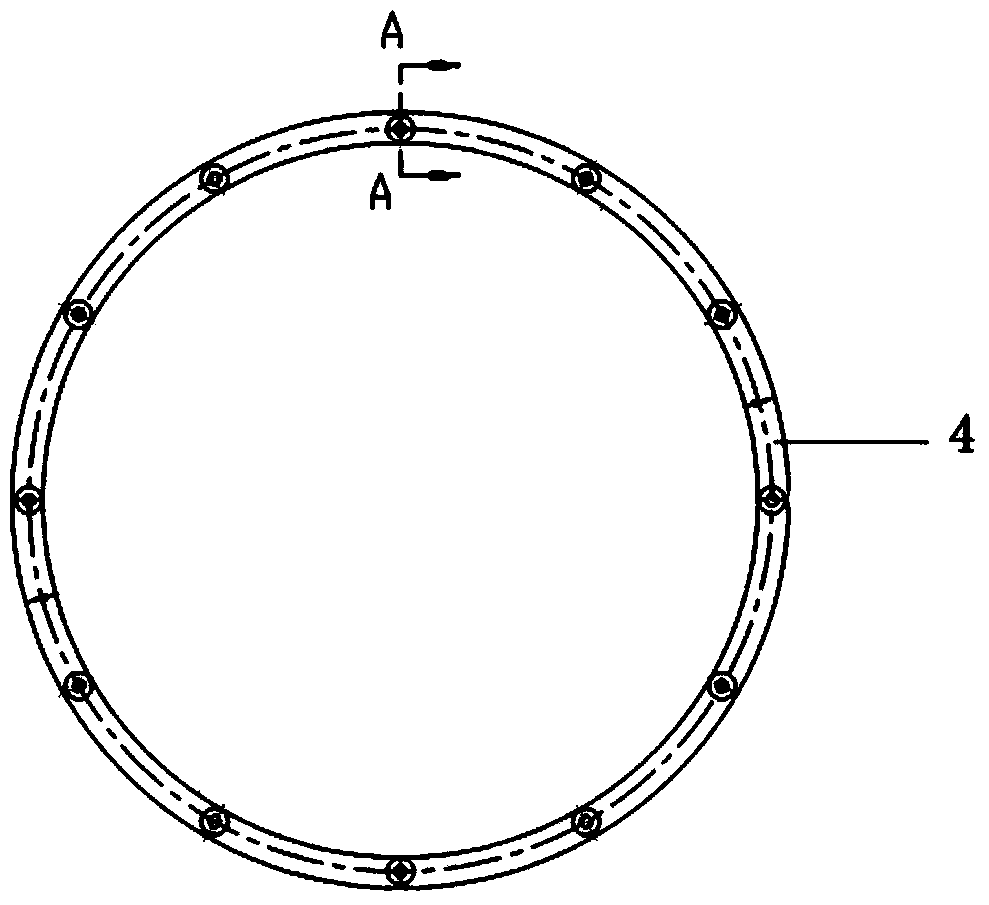

Assembling method for bogie wheel disc assembly of tracked vehicle

InactiveCN104129228AFirmly connectedImprove impact resistanceWheel assembling toolsBogieWear resistant

The invention discloses an assembling method for a bogie wheel disc assembly of a tracked vehicle. The assembling method is characterized by comprising the following steps: concave connecting holes are formed in a wear resistant steel ring; bolt holes which are aligned to the concave connecting holes are formed in a bogie wheel; the wear resistant steel ring is fastened and connected to the bogie wheel through fastening bolts; the concave connecting holes in the wear resistant steel ring are sealed through welding. The bogie wheel is made of aluminum alloy or magnesium alloy materials, and the wear resistant steel ring is made of 38CrSi steel. A special connection mode combining the threaded mechanical connection and the welding and fastening sealing enables the bogie wheel and the wear resistant steel ring to be firmly combined into a whole to form the bogie wheel disc assembly. Compared with the prior art, the method has the advantages that the firmness of the connection of the parts made of two kinds of materials is higher, and the falling-off is prevented; the surface is complete and free of assembling traces, and the quality is high; and the impact resistant performance of the parts manufactured according to the process is far better than that of the parts manufactured according to the conventional process, and a technical support is provided for further improving the motor performance of the tracked vehicle.

Owner:BEIJING NORTH VEHICLE GROUP CORP

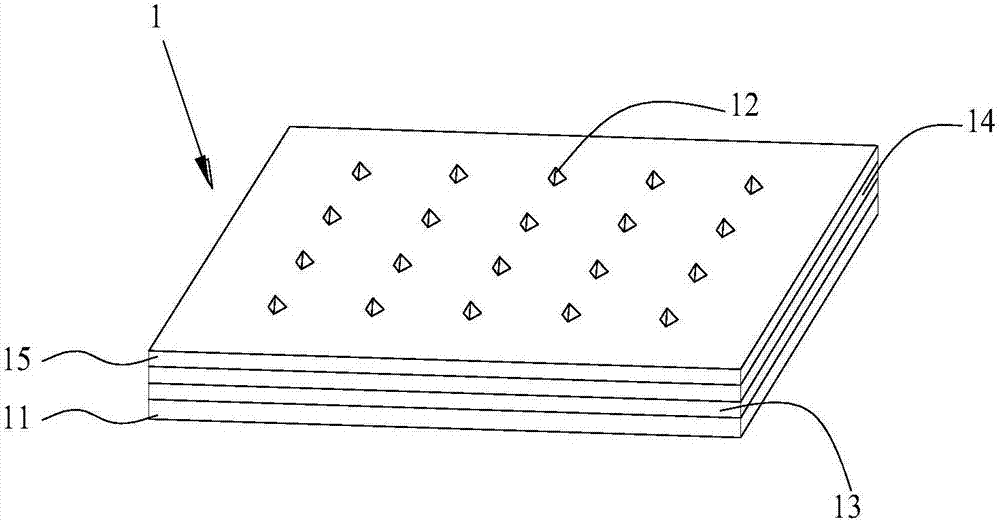

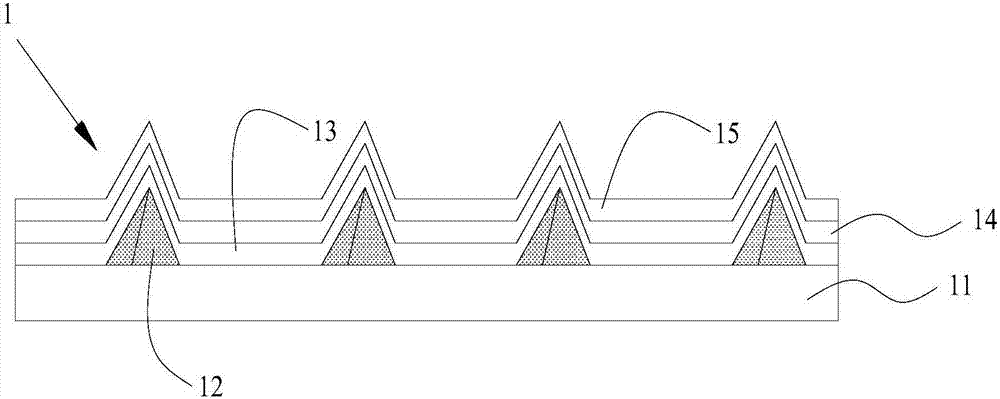

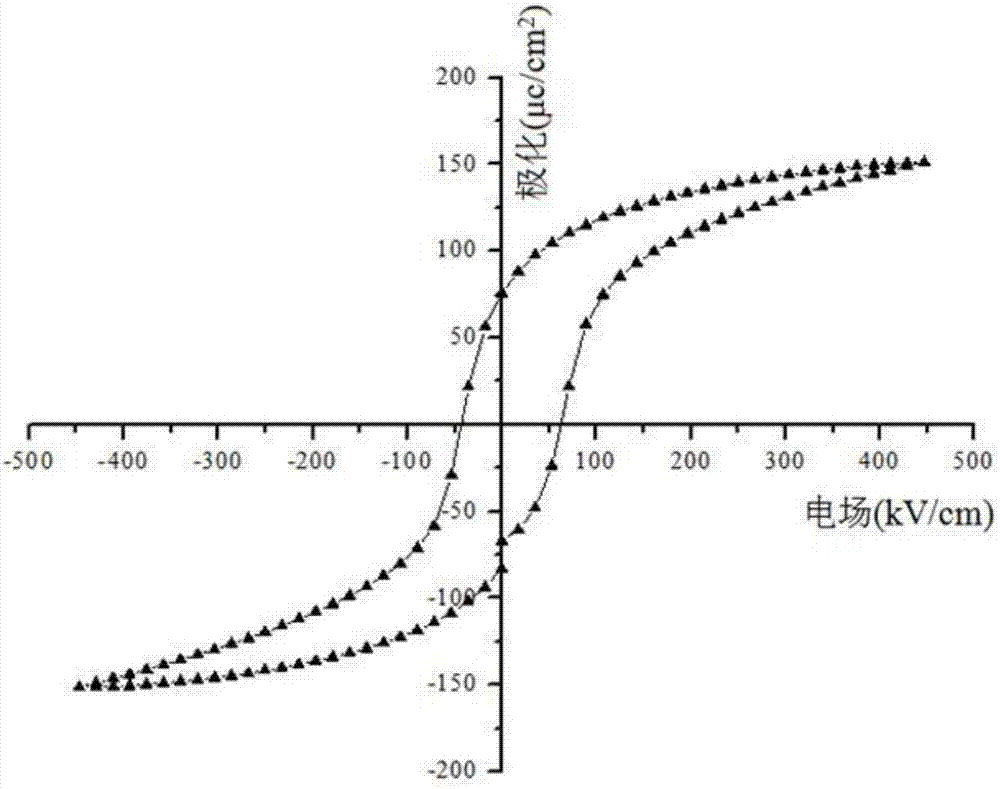

Piezoelectric film and preparation method thereof

ActiveCN107346802AEfficient releaseSurface integrityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionStress reliefLiquid phase

The invention discloses a preparation method of a piezoelectric film. The preparation method comprises the steps of: preparing a steady-state liquid-phase precursor, wherein composition of the steady-state liquid-phase precursor matches that of the piezoelectric film; providing a base, and preparing protrusions serving as stress relief structures on the surface of the base; sequentially preparing an isolation layer and an electrode layer on the surfaces of the base and the protrusions so as to form a substrate; and preparing the piezoelectric film by painting the steady-state liquid-phase precursor on the surface, away from the base, of the substrate and performing primary annealing. According to the preparation method disclosed by the invention, the stress caused by the too large area of the base is effectively relieved through preparing the substrate having the stress relief structures, thus the piezoelectric film with the advantages of being large in area, crack-free and good in performance is prepared. The invention further discloses the piezoelectric film prepared by adopting the preparation method.

Owner:SHANGHAI REALFAST DIGITAL TECH CO LTD

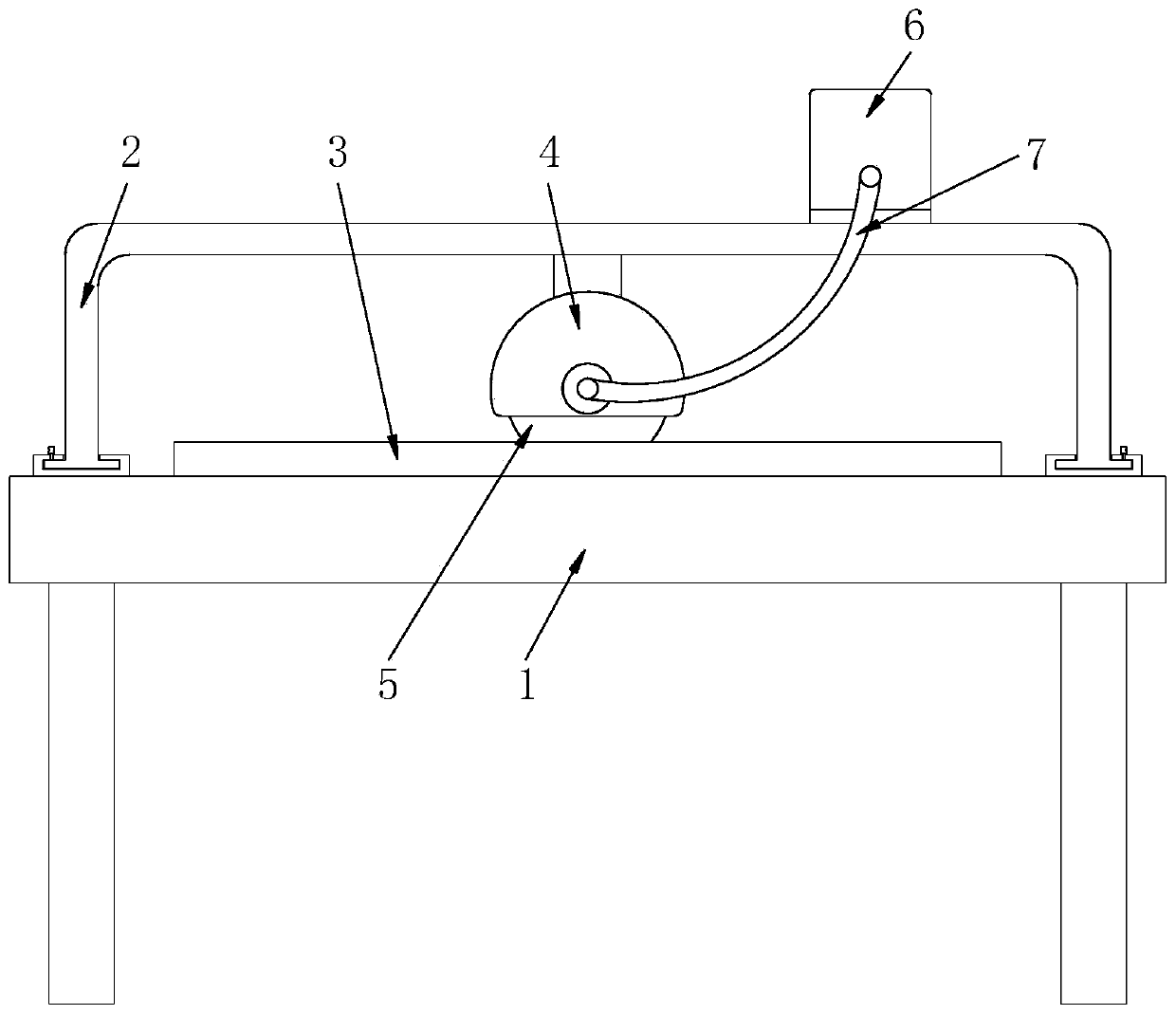

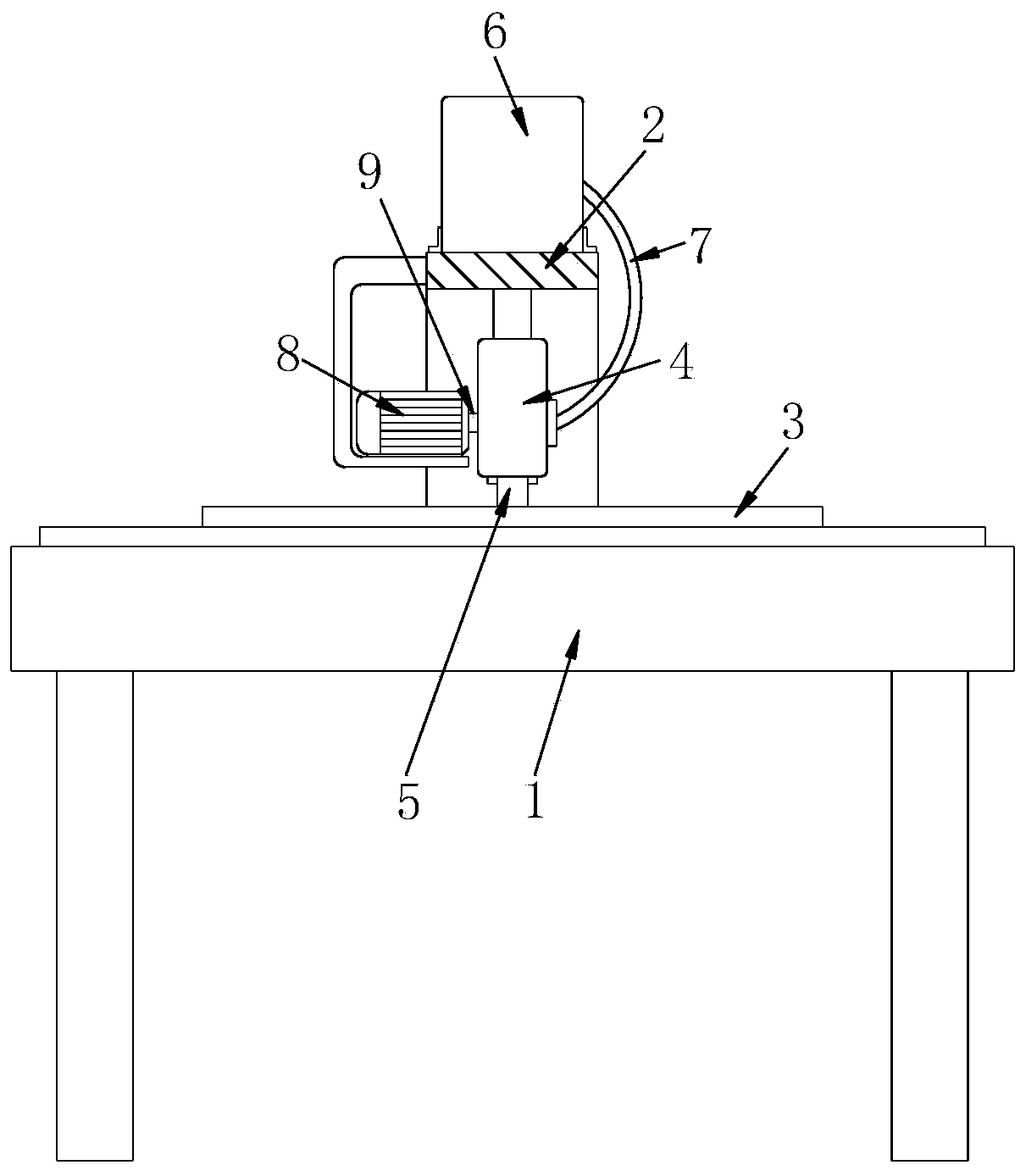

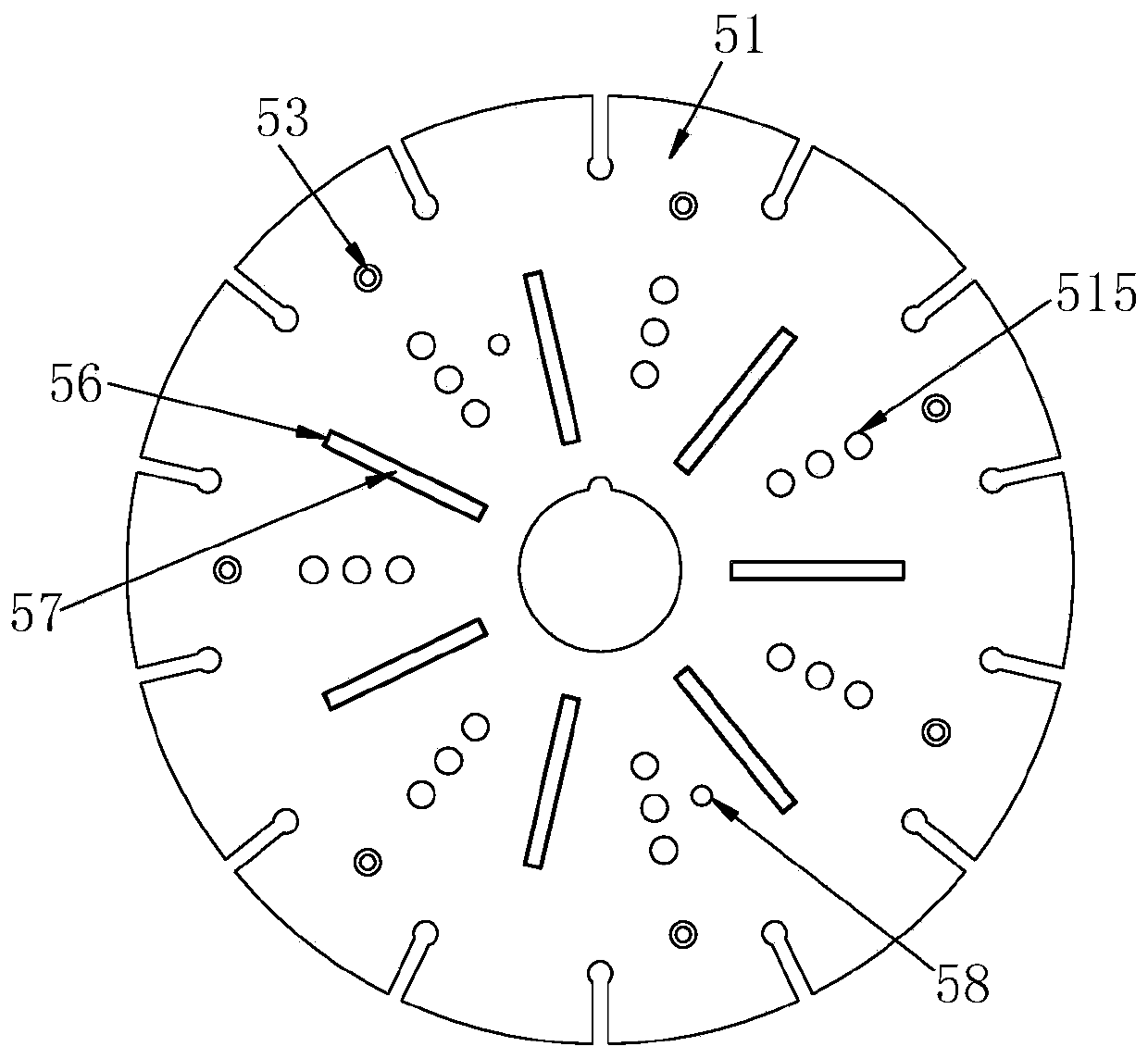

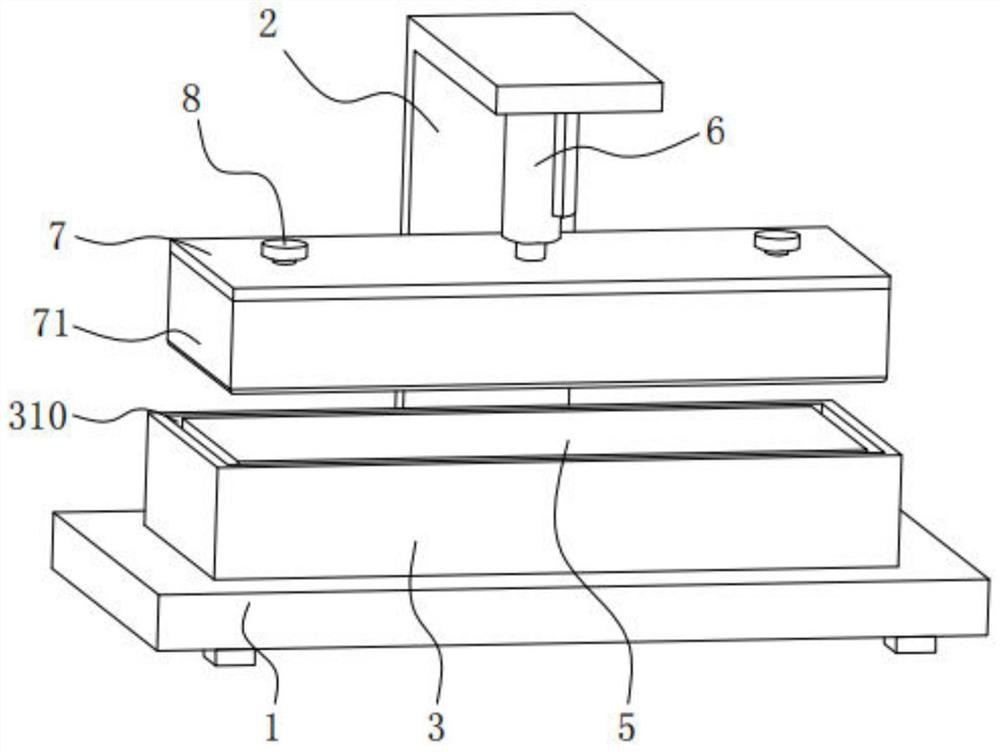

Cutting and edging all-in-one machine for building curtain wall marble plate material

ActiveCN111015975AReduce wasteReduce lossEdge grinding machinesWorking accessoriesElectric machineCoupling

The invention relates to a cutting and edging all-in-one machine for a building curtain wall marble plate material. The cutting and edging all-in-one machine comprises a workbench surface, a supporting frame, a placement plate, a protection cover, a cutting component, a water tank, a water feeding pipe, a motor and a driving component, wherein the upper end of the workbench surface is provided with the supporting frame; the water tank is placed on the top of the supporting frame; one end of the bottom of the water tank is connected with the water feeding pipe; the center position of the bottomof the supporting frame is provided with the protection cover; the internal center position of the protection cover is provided with the driving component; the outer side of the driving component isprovided with the cutting component; one side of the top of the supporting frame is welded with an L-shaped supporting plate; the upper end of the L-shaped supporting plate is provided with a motor; and the output shaft of the motor is connected with one end of the driving component through a coupling. By use of the cutting and edging all-in-one machine, an internal water discharging way is adopted for carrying out a cutting operation, in addition, dot-matrix arrangement is adopted, so that water resources are effectively saved, a good cooing effect is performed, and meanwhile, through a multistage cutting way, a situation that marble is broken when the marble is cut can be solved.

Owner:宜春市中联石材有限公司

Method for continuous casting production of YQ450NQR1 Z-type steel bloom

The invention discloses a method for continuous casting production of a YQ450NQR1 Z-type steel bloom in the field of steel metallurgy. The method is mainly improved in the molten steel continuous casting stage, during continuous casting, a tubular crystallizer with the section size consistent with that of a casting blank is utilized, and special continuous casting crystallizer protective slag is used in cooperation, wherein according to physical property index requirements of the protective slag, the viscosity is 1.00-1.02 Pa, the alkalinity 0.83-0.85, the softening temperature is 1130-1136 DEG C, the hemispherical temperature is 1190-1196 DEG C, the flowing temperature is 1200-1202 DEG C, and the slag consumption in the application process is 0.55-0.62 kg of slag per ton of steel. On thebasis, the appropriate crystallizer cooling strength, continuous casting drawing speed, crystallizer electromagnetic stirring parameters and superheat degree control are also utilized so that a billetcan form a blank shell complete in surface and uniform in thickness in the crystallizer, the method particularly has a remarkable effect on controlling cast blank shell quality defects caused by peritectic transformation linear contraction, the problems of rolling and cracking caused by the cast blank shell quality defects are solved, and an important foundation is laid for controlling cracking defects of Z-type steel in the later rolling stage.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

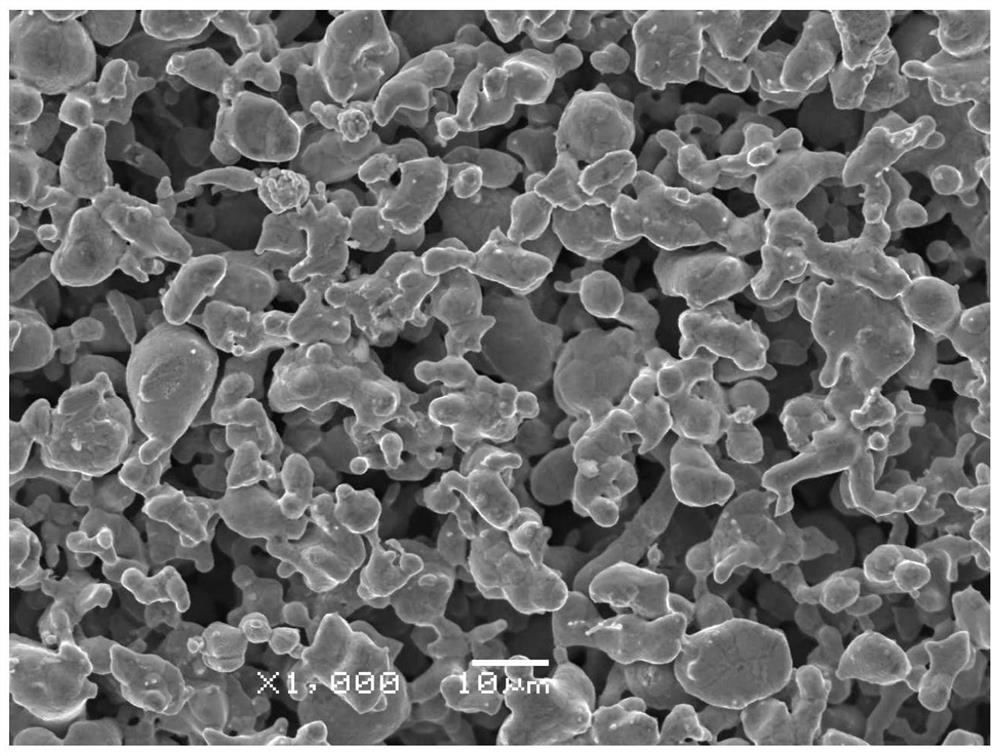

Electromagnetic wave absorbent large in radius-thickness ratio and preparation method thereof

ActiveCN106876079ASurface integrityLess cold weldingTransportation and packagingMetal-working apparatusEnvironmentally friendlyMaterials science

The invention provides an electromagnetic wave absorbent large in radius-thickness ratio and a preparation method thereof. The method comprises the steps that laminarization treatment is mainly conducted on magnetically soft alloy powder on the condition that a solvent medium and a specific proportion-specified and environmentally friendly lubricant exist, then, drying is conducted, and particularly after specified dewaxing process heat treatment, annealing treatment and other processes, the electromagnetic wave absorbent large in radius-thickness ratio is formed. The particle size and morphology are uniform, the surface is mellow, full and smooth, and the magnetic property is excellent.

Owner:广州蓝磁新材料科技有限公司

Preparation method of red electrophoresis liquid microcapsule

InactiveCN101920181AGood dispersionUniform particle size distributionMicroballoon preparationNon-linear opticsOptical transparencyElectrophoresis

The invention aims at providing a preparation method of a red electrophoresis liquid microcapsule. The red electrophoresis liquid microcapsule prepared by the method has the advantages of good dispersibility, uniform particle size distribution, sensitive electrical field response, quick and reversible bistable state characteristic, short electrical field response time, transparent capsule wall, good suspension stability, good color development effect, small particle size, complete shape, smooth surface, optical transparency, good mechanical strength and no adhesion among microcapsules. The method has easily controlled reaction conditions and is applicable to large-scale industrial production.

Owner:SHENZHEN UNIV +1

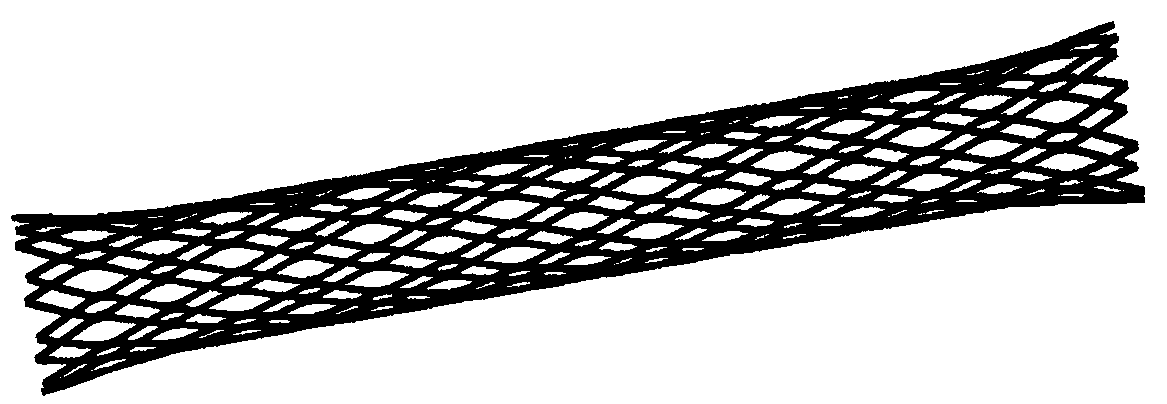

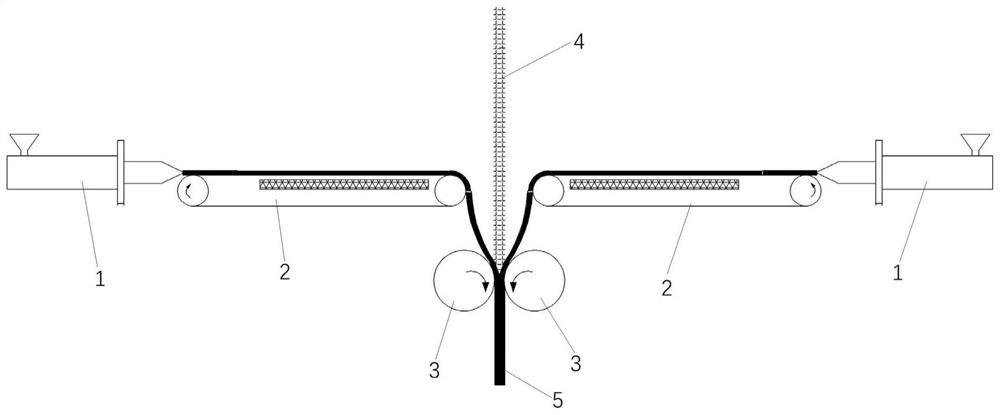

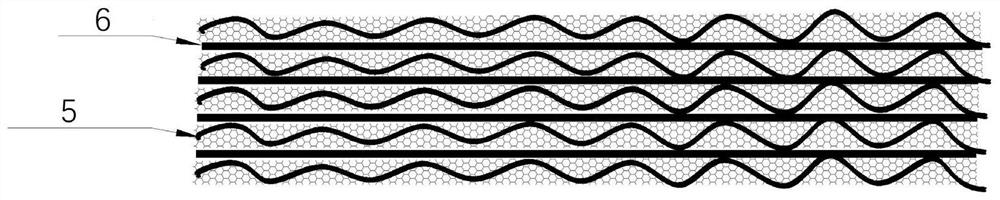

Preparation method of powder net composite porous metal film

PendingCN113181782AHigh filtration precisionStrong tensile strengthSemi-permeable membranesDispersed particle filtrationThin membranePlasticizer

The invention discloses a preparation method of a powder net composite porous metal film, which comprises the steps of 1, uniformly mixing metal powder with a plasticizer, a thickening agent and an organic solvent or deionized water according to a certain proportion to prepare high-viscosity slurry; 2, extruding the high-viscosity slurry into a strip-shaped film blank through a slit-type die opening by using an extruding machine, conveying the strip-shaped film blank to two rolling mills through a conveying belt, and rolling the strip-shaped film blank into a strip-shaped powder net composite porous metal film blank through composite film blanks on the two sides and a composite single-layer metal wire net in the middle; and 3, laying an isolating layer on the strip-shaped powder net composite porous metal film blank through aluminum oxide powder, conducting degreasing and sintering in a hydrogen sintering furnace, and then obtaining the powder net composite porous metal film. The preparation process is simple, the cost is low, the efficiency is high, and the prepared powder net composite porous metal film is uniform in pore size distribution, small in maximum pore size, high in permeability coefficient and capable of being widely applied to the fields of flue gas dust removal, water purification and the like.

Owner:WESTERN BAODE TECH CO LTD

Red electrophoresis liquid and preparing method thereof and preparing method of microcapsule thereof

InactiveCN101408706AGood dispersionUniform particle size distributionOrganic dyesMicroballoon preparationChemistrySurface-active agents

The invention aims at providing a red electrophoresis liquid, comprising permanent bordeaux F5R with the content being 2-4mg / ml, a charge control agent which is dehydrogenated tallow secondary amine with the content being 0.1-0.6mg / ml, a surface active agent span-80 or polyethylene wax with the content being 1-2mg / ml, and dispersive medium such as tetrachloroethylene or phenyl ethylene. The invention provides a method for preparing the red electrophoresis liquid. The red electrophoresis liquid microcapsule prepared by the method has good dispersivity, even granularity distribution, sensitive response on an electric field, and fast and reversible double steady-state characteristics, and the response time of the electric field is short. In addition, the red electrophoresis liquid microcapsule prepared by the method has transparent cystwall, good suspension stability and chromogenic effect, smaller grain diameter, integral shape, smooth surface, transparent optical property, good mechanical strength, and no conglutination between microcapsules. The method has easily controllable reaction conditions, which is suitable for large-scale manufacturing production.

Owner:SHENZHEN UNIV +1

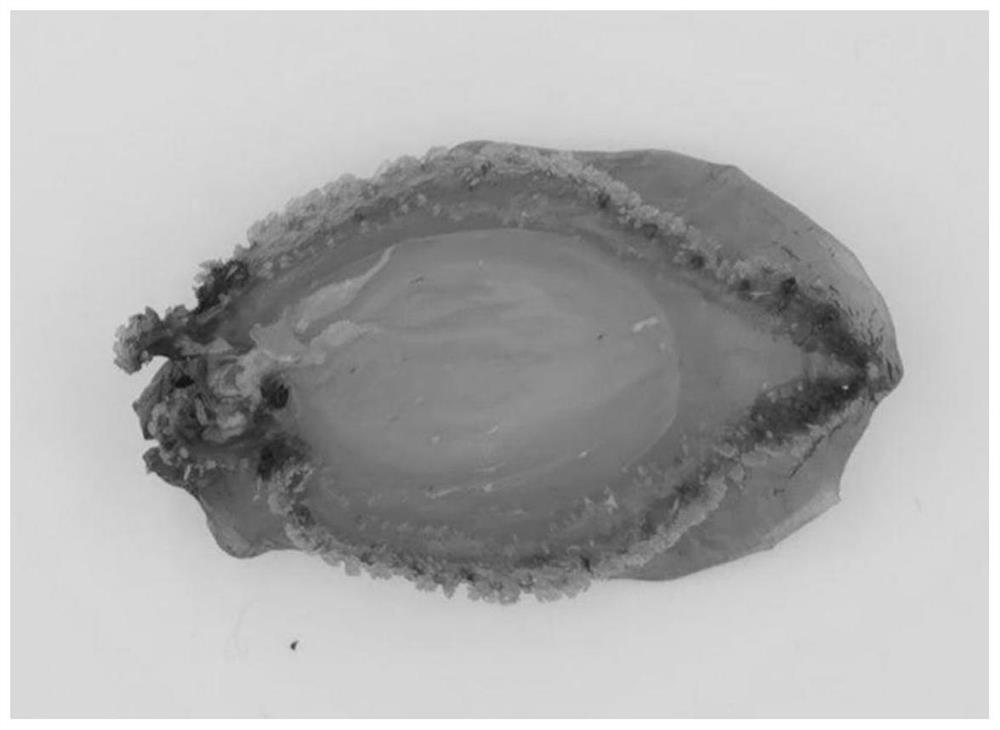

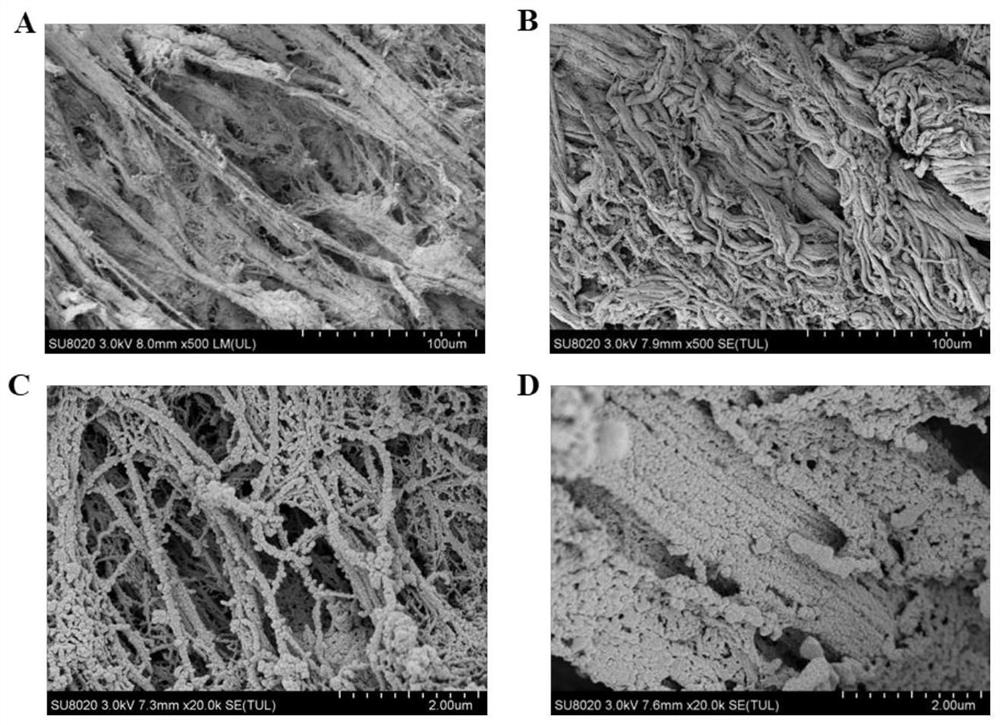

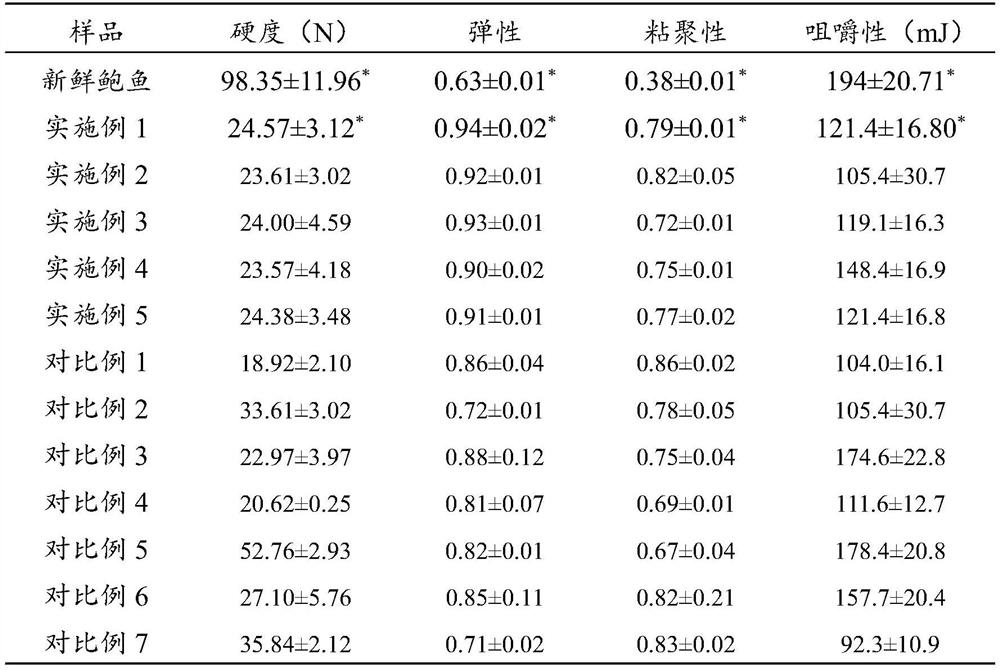

Soft boiled dried abalone and preparation method thereof

PendingCN113519793AImprove texture qualityImprove qualityFood dryingMeat/fish preservation by dryingBiotechnologyProtein molecules

The invention provides soft boiled dried abalone and a preparation method thereof, and belongs to the technical field of food processing. According to the method, the abalones are subjected to enzymolysis treatment through protease, so that protein molecules in the abalones form isopeptide bonds in the molecules or among the molecules, crosslinking is performed, the network structure strength of abalone muscles is greatly improved, the viscosity of abalone products is improved, the flavor and taste are improved, and the phenomenon of edge breaking in the abalone drying process is avoided. The soft boiled dry abalones obtained by the preparation method provided by the invention not only have complete surfaces and good texture quality, but also are easy to water-swollen, so that the quality of the dry abalones is greatly improved; meanwhile, the preparation method provided by the invention is simple in process, easy in control of production conditions, short in preparation period and suitable for industrial mass production.

Owner:CHINA AGRI UNIV

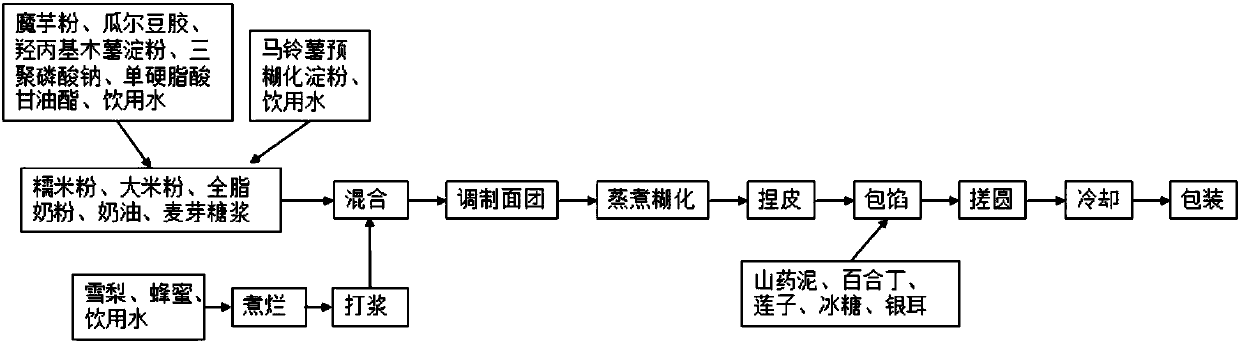

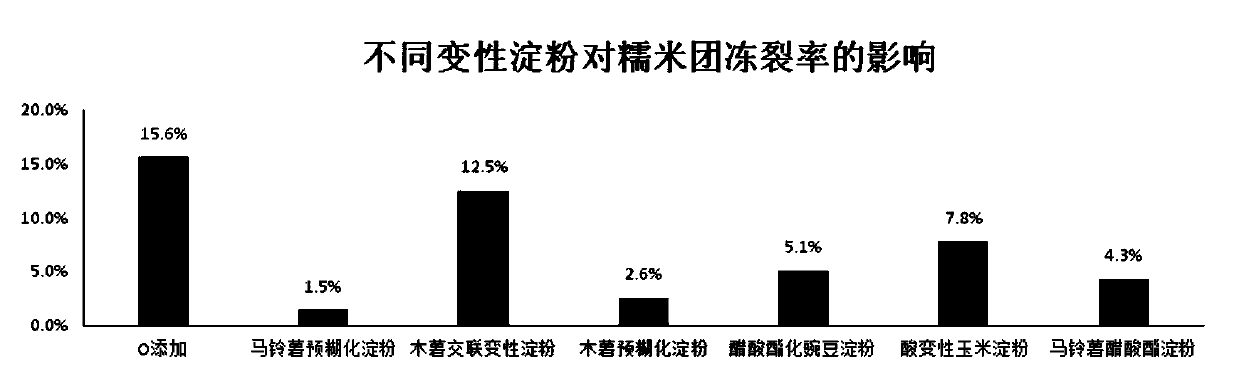

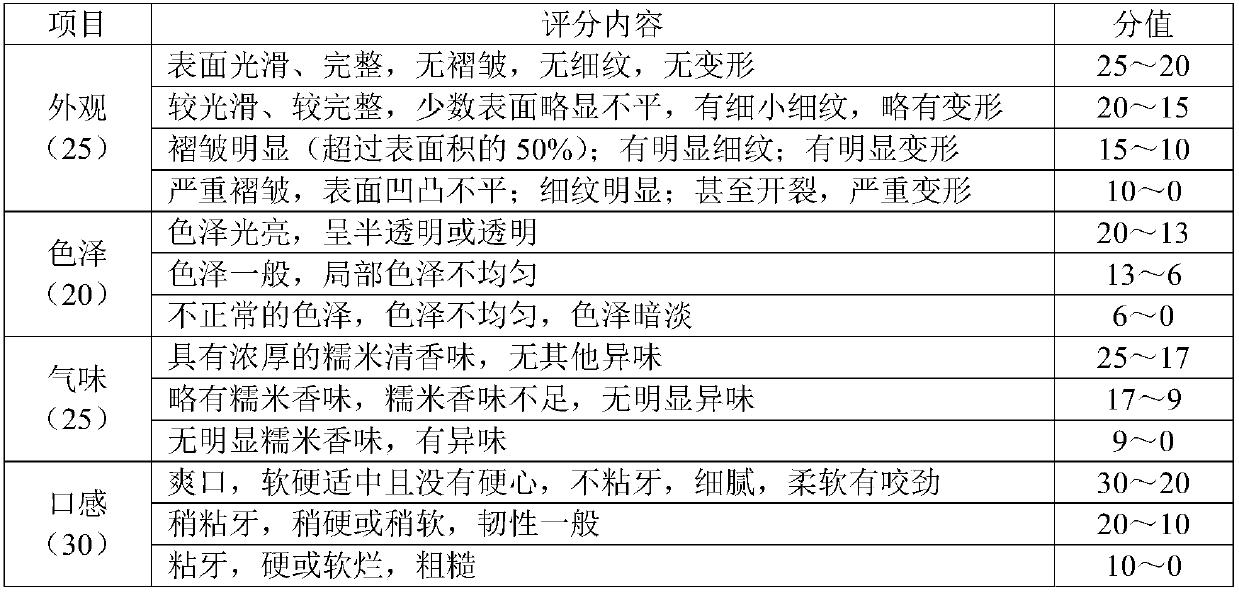

Lung-heat clearing glutinous rice ball and making method thereof

ActiveCN108013334ASimple processNo hard heartFood coatingFood ingredient as mouthfeel improving agentFrost crackFine line

The invention provides a lung-heat clearing glutinous rice ball containing Chinese yam, tremella, snow pear, lotus seed, lily, honey and other health care food materials. The glutinous rice ball is refreshing, neither too hard nor too soft, is free of hard core, non-sticky to teeth, fine in taste, soft and al dente, and has good elasticity, the glutinous rice ball has a smooth and complete surface, is free of fold, fine line and deformation, and has a fine texture structure. And after refrigeration or freezing, the frost crack rate is low, and the product defect rate is low. The invention alsoprovides a making method of the lung-heat clearing glutinous rice ball, the making process is simple, avoids starchy sauce boiling, blanching or other procedures, and is more suitable for enlarged production.

Owner:COFCO GROUP +1

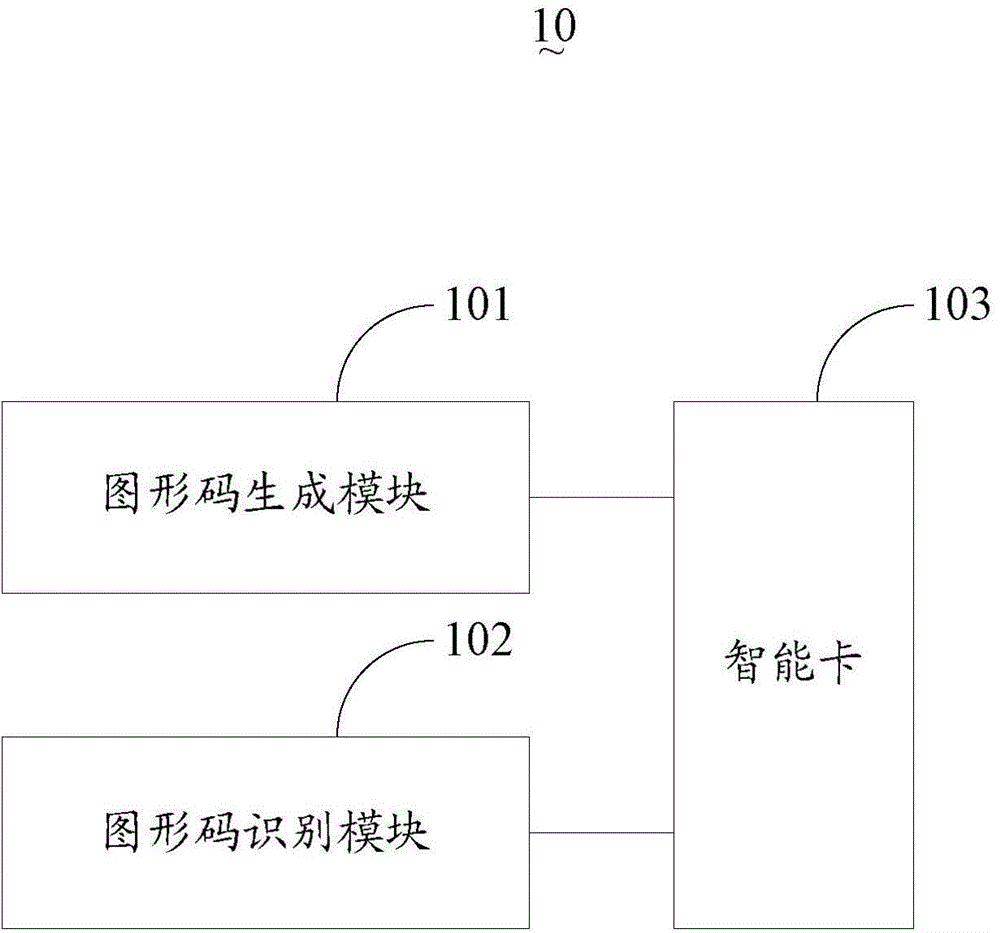

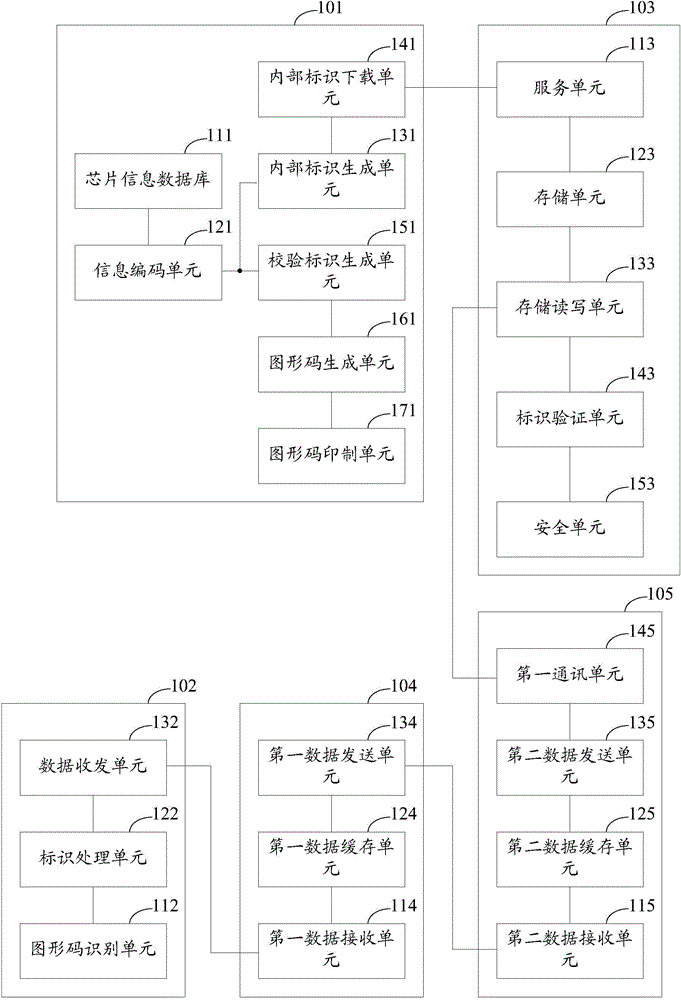

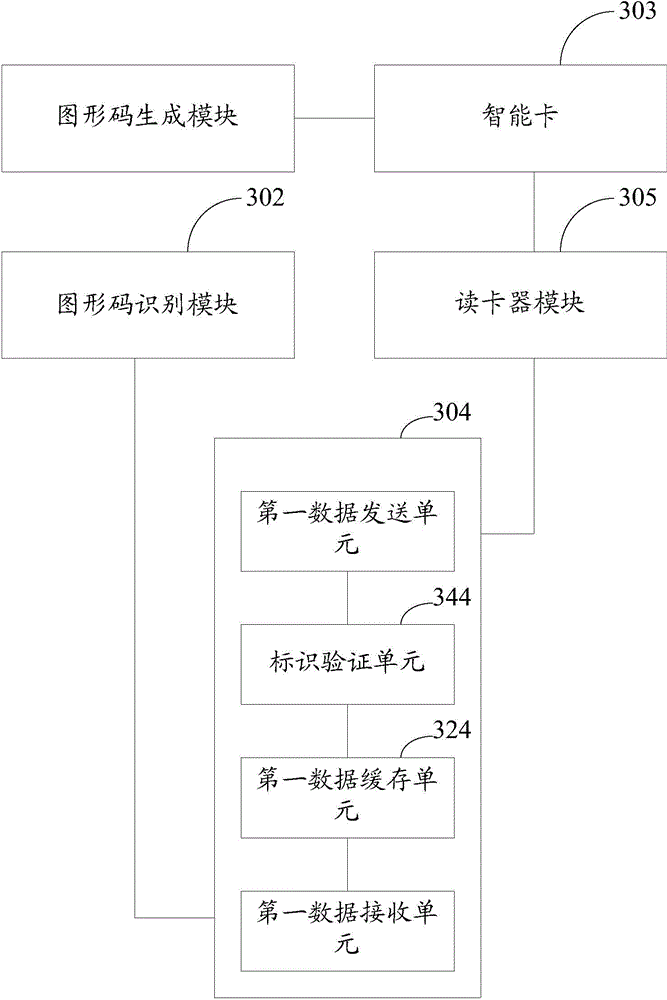

System and method for protecting complete surface of intelligent card

InactiveCN105224852ASurface integritySimple designDigital data authenticationGraphicsInternal identifier

Owner:NATIONZ TECH INC

Instant licorice snack food and preparation method thereof

ActiveCN107950946AStrong shape plasticityFlat surfaceFood ingredient as anti-caking agentInorganic compound food ingredientsSnack foodFood products

The present invention provides instant licorice snack food and belongs to the technical field of snack food. The instant licorice snack food is prepared from the following raw materials in parts by weight: 40-60 parts of licorice, 10-20 parts of cassava, 10-20 parts of poria cocos, 8-20 parts of coconut milk, 5-15 parts of honey, 0.05-0.10 part of a swelling agent and 0.1-0.5 part of an anti-caking agent. The instant licorice snack food has a unique licorice flavor, is sweet and palatable, complete in shapes, smooth on surface, light brown in color and luster, glossy, harmonious and soft in aroma, pure, and delicate in taste.

Owner:LUOHE MEDICAL COLLEGE

Copper foil improvement method

PendingCN114633539AClean surfaceImprove fitLamination ancillary operationsLaminationCopper foilTemperature treatment

The invention provides a copper foil improvement method. The copper foil improvement method comprises the following steps: S1, selecting a copper foil raw material; s2, cutting the copper foil raw material in a dust-free environment; s3, the cut copper foil is installed on a pressing device, and cutting and pressing are conducted through a concentric-square-shaped mold; s4, in the pressing process, the constant-temperature state is maintained; and S5, cooling the laminated copper foil in a natural environment, and molding the cooled copper foil. According to the copper foil improvement method provided by the invention, the copper foil raw material is cut in a dust-free environment before being pressed, so that the surface of the cut copper foil is complete and free of air attachments, the surface of the copper foil is clean and tidy in the pressing process, and constant-temperature treatment in the pressing process can effectively improve the laminating degree of pressing and enhance the pressing quality of the copper foil; therefore, the forming quality of the laminated copper foil is improved.

Owner:AOSHIKANG TECH CO LTD

Method for controlling surface quality of YQ450NQR1 zed bar bloom

The invention discloses a method for controlling the surface quality of a YQ450NQR1 zed bar bloom in the field of ferrous metallurgy, which mainly improves a molten steel continuous casting stage, a tubular crystallizer which is consistent with the section size of a casting blank during continuous casting is used and special continuous casting crystallizer protective slag is matched, wherein the physical property indexes of the protective slag are as follows: the viscosity is 0.98-0.99Pa. S, the alkalinity is 0.80-0.82, the softening temperature is 1129-1133 DEG C, the hemispherization temperature is 1196-1199 DEG C, the flow temperature is 1203-1204 DEG C, the slag consumption is 0.52-0.56 kg / t steel in an application process. According to the invention, the large-size-section tubular crystallizer is used, and the special crystallizer protective slag is matched, so that the billet can form a billet shell with a complete surface and an uniform thickness in the crystallizer, and the control effect on the surface quality defect of the billet caused by the shrinkage of the peritectic phase transition line is remarkable, the problem of rolling and pulling crack caused by the surface quality defect of the casting blank is solved, and an important foundation for controlling the pulling crack defect in the later rolling stage of the zed bar is laid.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Red electrophoresis liquid and preparing method thereof

InactiveCN101408706BGood dispersionUniform particle size distributionOrganic dyesMicroballoon preparationActive agentSurface-active agents

The invention aims at providing a red electrophoresis liquid, comprising permanent bordeaux F5R with the content being 2-4mg / ml, a charge control agent which is dehydrogenated tallow secondary amine with the content being 0.1-0.6mg / ml, a surface active agent span-80 or polyethylene wax with the content being 1-2mg / ml, and dispersive medium such as tetrachloroethylene or phenyl ethylene. The invention provides a method for preparing the red electrophoresis liquid. The red electrophoresis liquid microcapsule prepared by the method has good dispersivity, even granularity distribution, sensitive response on an electric field, and fast and reversible double steady-state characteristics, and the response time of the electric field is short. In addition, the red electrophoresis liquid microcapsule prepared by the method has transparent cystwall, good suspension stability and chromogenic effect, smaller grain diameter, integral shape, smooth surface, transparent optical property, good mechanical strength, and no conglutination between microcapsules. The method has easily controllable reaction conditions, which is suitable for large-scale manufacturing production.

Owner:SHENZHEN UNIV +1

Preparation method of cocoa polyphenol chewable tablet

InactiveCN106109512AComplete formFlat surfaceDispersion deliveryMetabolism disorderChemistryCocoa polyphenols

The invention relates to a preparation method of a cocoa polyphenol chewable tablet, and belongs to the technical field of processing of polyphenols. Aiming at the problems that polyphenol health-care food is slowly absorbed and low in bioavailability because the drug needs a disintegration process and the drug dissolution is slow and the polyphenol health-care food is inconvenient to carry and take and cannot be taken on time in a water shortage state, the invention provides the preparation method of the cocoa polyphenol chewable tablet. Fresh cocoa fruits are used as a raw material and are shelled, baked, peeled and ground to obtain a cocoa powder; the cocoa powder is degreased and then polyphenols enriched in the cocoa are extracted, and the cocoa polyphenol extract liquid is prepared and is concentrated and dried into a powder; the powder is mixed with sucrose, lactose, mannitol and citric acid, starch pulp is added for adhesion, sieving granulation is performed by an extrusion method, magnesium stearate is added as a lubricant, tabletting forming is performed by a single charge tabletting machine, and the tablet is dried to obtain the cocoa polyphenols chewable tablet.

Owner:郭迎庆

Cassia twig tablet preparation process

InactiveCN105617298AImprove quality stabilityEasy to takeAntipyreticMetabolism disorderAdditive ingredientMixed materials

The invention provides a cassia twig tablet preparation process, which comprises the following steps of: 1, drying cassia twig, peony roots, ginger, radix glycyrrhizae preparata and dates in a drying machine at the temperature being 60 DEG C, and then, adding the ingredients into a pulverizing machine for pulverizing the ingredients; 2, taking and mixing cassia twig powder, peony root powder, ginger powder, radix glycyrrhizae preparata powder and date powder, and uniformly stirring the mixture to prepare main material powder; 3, adding a diluting agent, a wetting agent, a lubricating agent and a disintegrating agent, and uniformly mixing the mixture to prepare a main and auxiliary mixed material; and 4, pressing the main and auxiliary mixed material into tablets in a single-punch tablet press. The cassia twig tablet preparation process has the advantages that cassia twig decoction is prepared into traditional Chinese medicine tablets; the quality stability of the medicine is improved, so that a patient feels convenient when taking, carrying, transporting and storing the medicine; the prepared cassia twig tablets are gray brown tablets; the smell is fragrant; the tablet shapes are consistent; the tablet surfaces are complete; the surfaces are smooth; the edges are regular; the color and luster are uniform; and the weight difference limitation, the hardness, the friability and the disintegration time limit of the cassia twig tablet conform to tablet medicine specifications.

Owner:王磊

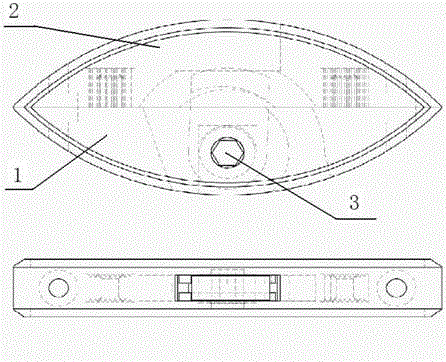

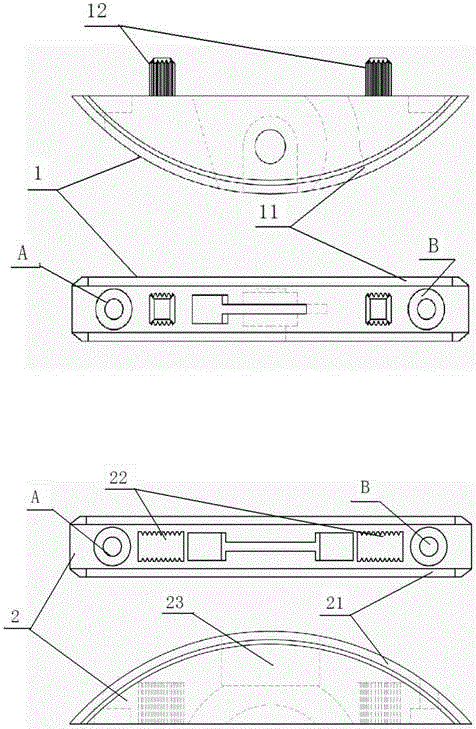

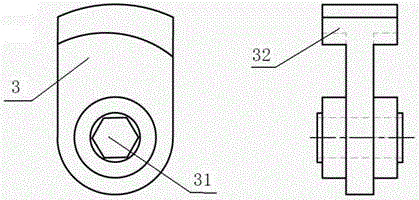

Crescent connecting assembly

The invention discloses a crescent connecting assembly. The crescent connecting assembly comprises a connector, a connecting base and a locking clamp. One end of the connector is in the shape of an arc with convex grooves in two sides. The other end of the connector is a plane provided with one or more positioning convex stands. The angle-adjustable locking clamp is arranged in the middle of the connector. One end of the connecting base is in the shape of an arc with convex grooves in two sides. The other end of the connecting base is a plane provided with one or more positioning concave stands. An arc-shaped cavity which can contain the locking clamp is formed in the middle of the connecting base. The locking clamp is fixed to the middle of the connector. The head of the locking clamp is pulled to rotate by rotating an internal hexagonal hole in the tail end of the locking clamp by means of an internal hexagonal wrench, so that the connector is connected with or separated from the connecting base. The crescent connecting assembly is ingenious and novel in structural design; disassembly and assembly of a plate are achieved through the locking clamp, the surface of the assembled plate is complete, disassembly is free, no processing mark is left, and operation is easy and convenient.

Owner:金亚东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com