Self-heating cotton collection apparatus

A self-heating and cotton-collecting technology, which is applied in the field of cotton-collecting devices and multi-stage self-heating cotton-collecting devices, can solve the problems of wasting resources, hot air will be taken away, wasting energy, etc., and achieve the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

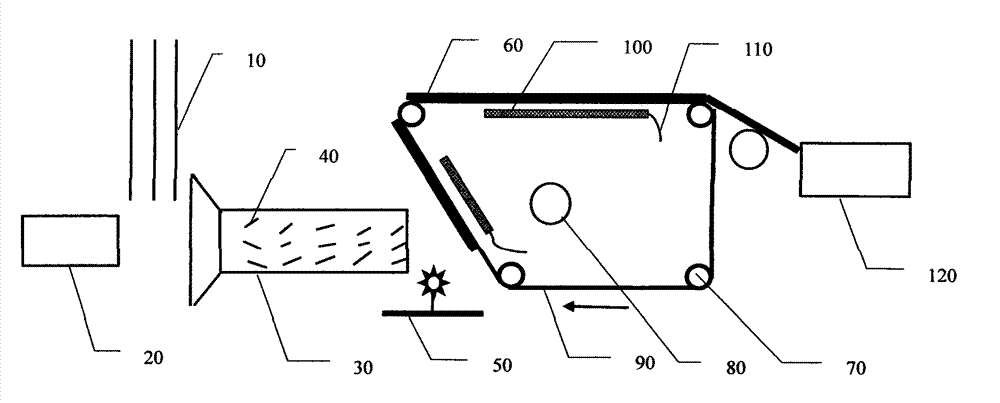

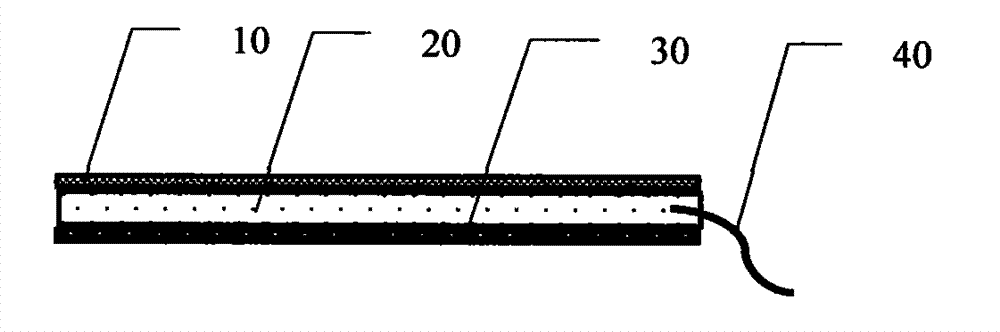

[0023] A multi-stage self-heating cotton collecting device is characterized in that it is composed of a cotton guiding chamber, a stainless steel mesh belt, a cotton collecting box, a negative pressure fan, a glue spraying pipe and an infrared radiation heat plate.

[0024] The cotton guide room is a cuboid with openings on both sides, with a length of 4m, a width of 1.0m, and a height of 0.4m. A glue spraying device is installed at the outlet on the right side of the cotton guide room; For drawing, the blowing speed of cotton is 5m / s.

[0025] The right side of the cotton guide room is an integrally closed cotton collection box, the box is an inverted right-angled trapezoid, the left side has a certain slope, the left side and the upper side have uniform holes, and the outside is equipped with a stainless steel mesh with holes With a negative pressure fan installed inside. The operating frequency of the stainless steel mesh belt is 50Hz.

[0026] There are two infrared radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com