Adhesive high temperature-resistant demoulding cloth and preparation method thereof

A technology with high temperature resistance and self-adhesiveness, applied in chemical instruments and methods, adhesives, non-polymer adhesive additives, etc., can solve problems such as reduced coating adhesion, mold damage, and harsh production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

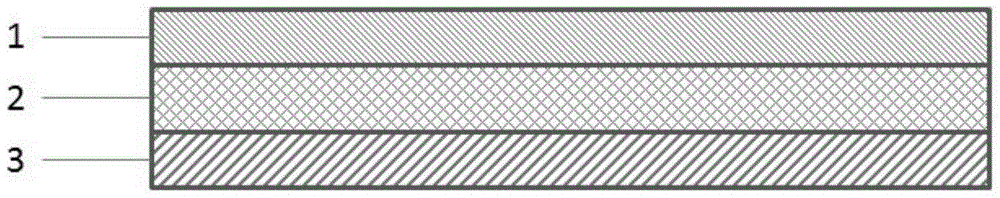

Image

Examples

preparation example Construction

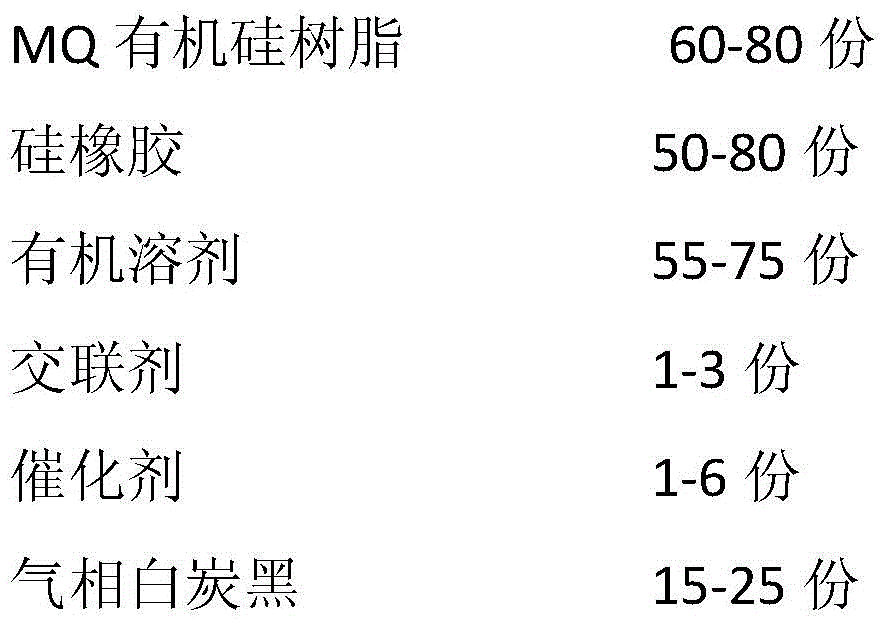

[0029] According to the present invention, the preparation method of the silicone pressure-sensitive adhesive includes the following steps: adding organic solvent, MQ silicone resin and silicone rubber in parts by mass to the reaction kettle, and slowly dripping Add the catalyst, drop it in 1-3 hours, then add the cross-linking agent and meteorological silica, continue the reaction at 130-150°C for 2 hours, and obtain the silicone pressure-sensitive adhesive after cooling.

[0030] Add the curing agent dibenzoyl peroxide to the silicone pressure-sensitive adhesive prepared above at a mass ratio of 1 wt%, and stir evenly to prepare a silicone pressure-sensitive collagen solution.

[0031] The present invention also provides a preparation method of self-adhesive high temperature resistant release cloth, comprising:

[0032] Step 1: hot-compressing polytetrafluoroethylene film and glass fiber cloth round rollers to obtain a glass fiber-reinforced anti-adhesive layer; the temperat...

Embodiment 1

[0036] Add 50 kg of xylene, 5 kg of toluene, 60 kg of MQ silicone resin and 50 kg of silicone rubber into the reaction kettle, and slowly add 5 kg of dibutyltin dilaurate dropwise after the temperature rises to 135 °C. Add 1 kg of phenyltributylketoxime silane to 15 kg of white carbon black, then continue to react at 140°C for 2 hours, and obtain a silicone pressure-sensitive adhesive after cooling, which is ready for use. When using, add curing agent dibenzoyl peroxide at a mass ratio of 1 wt%, stir evenly, and prepare silicone pressure-sensitive collagen solution.

Embodiment 2

[0038] Add 55 kg of xylene, 10 kg of toluene, 70 kg of MQ silicone resin and 55 kg of silicone rubber into the reaction kettle, slowly add 6 kg of dibutyltin dilaurate dropwise after the temperature rises to 135 °C, and the dropwise addition is completed in 1 hour. Add 1 kg of methyl tributyl ketoxime silane to 18 kg of white carbon black, then continue to react at 140°C for 2 hours, and obtain a silicone pressure-sensitive adhesive after cooling, which is ready for use. When using, add curing agent dibenzoyl peroxide at a mass ratio of 1 wt%, stir evenly, and prepare silicone pressure-sensitive collagen solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com