A method for heat preservation, energy saving and water drainage of building exterior walls

A technology for building exterior walls and thermal insulation layers, applied in thermal insulation, construction, building components, etc., can solve the problems of poor thermal insulation and waterproof performance, poor wind resistance, and large workload of thermal insulation layers, and achieve reliable thermal insulation and energy saving measures and good thermal insulation. Waterproof performance, the effect of reducing load-bearing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

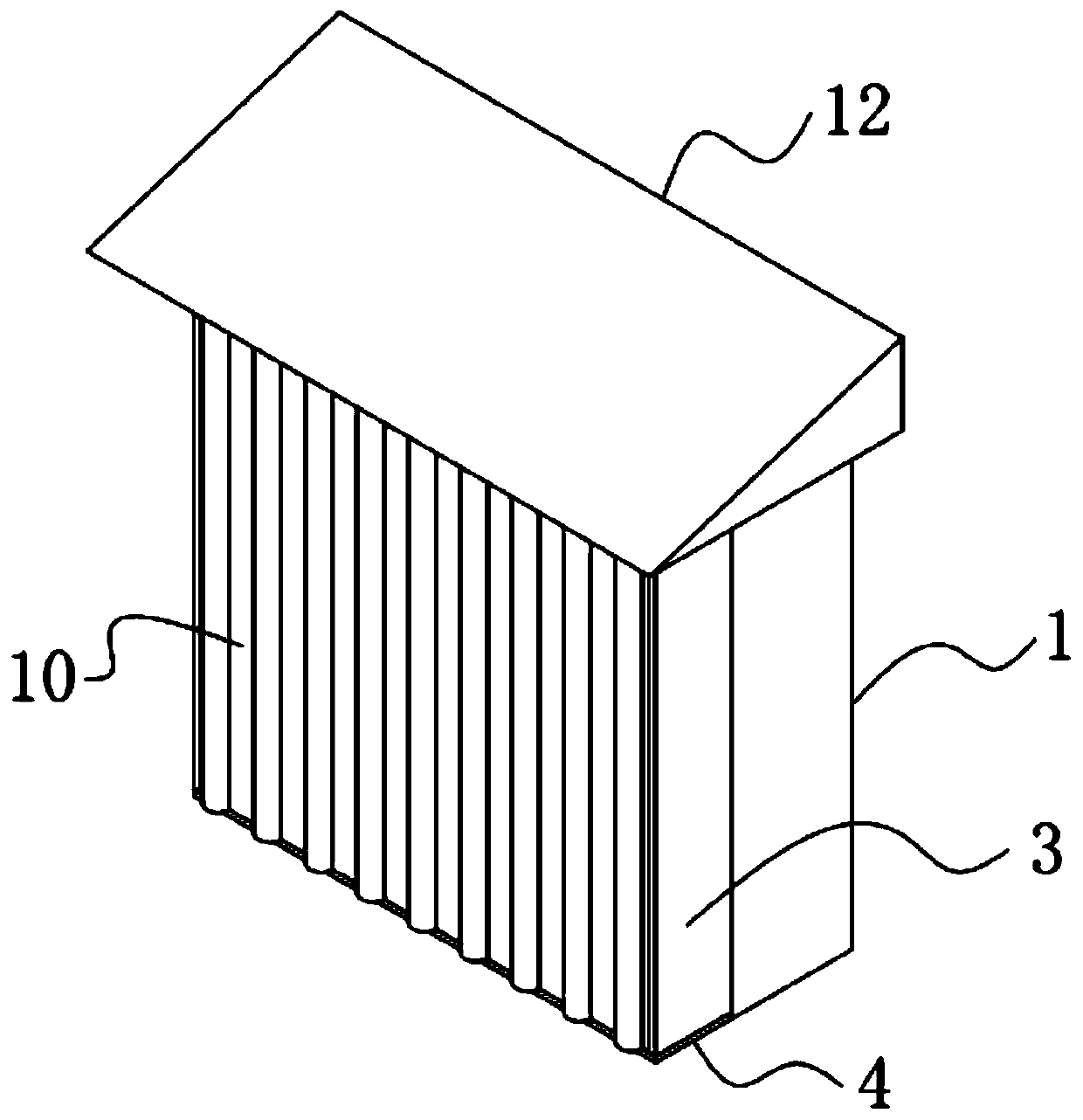

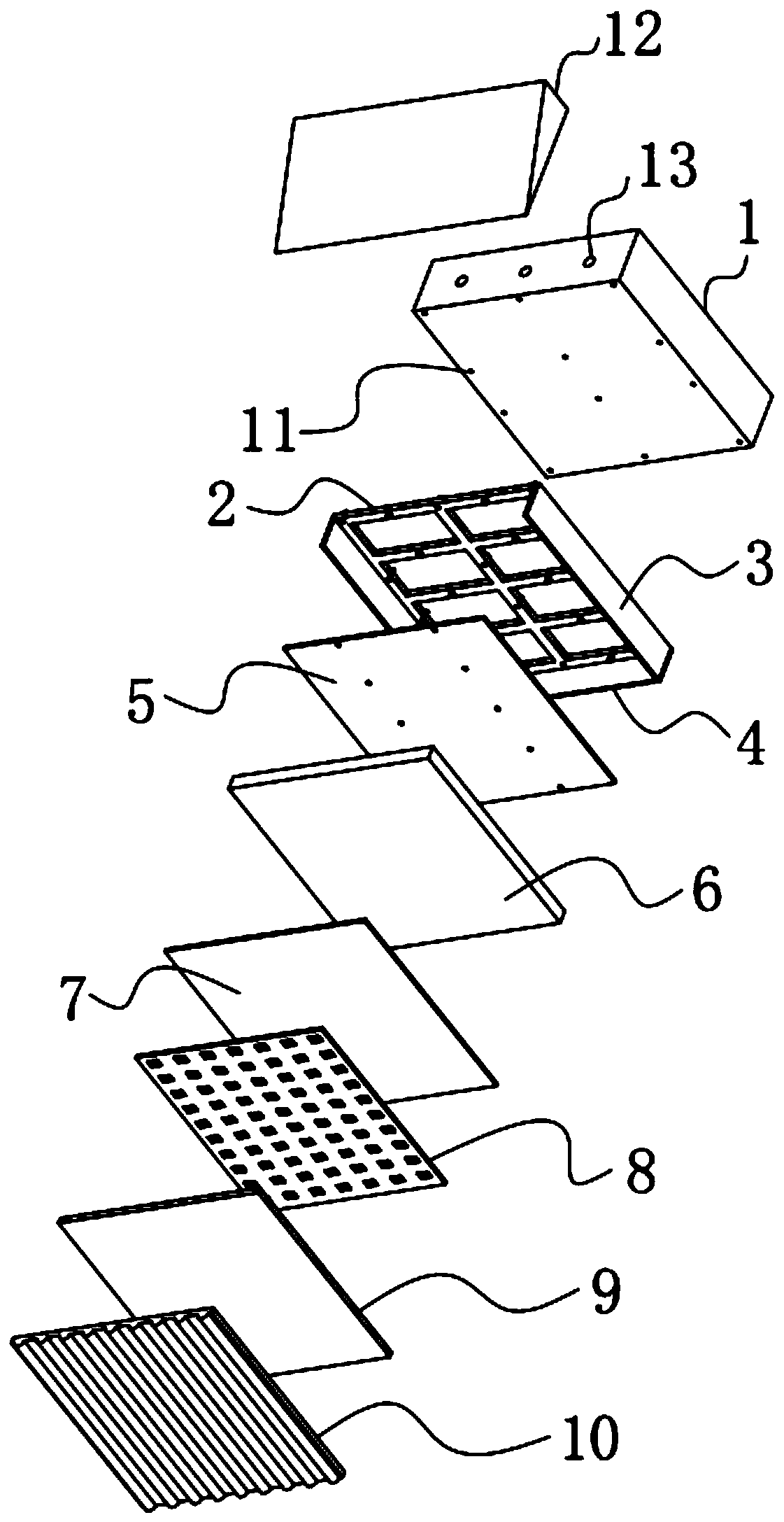

[0052] A method for heat preservation, energy saving and water drainage of building exterior walls, comprising the following steps:

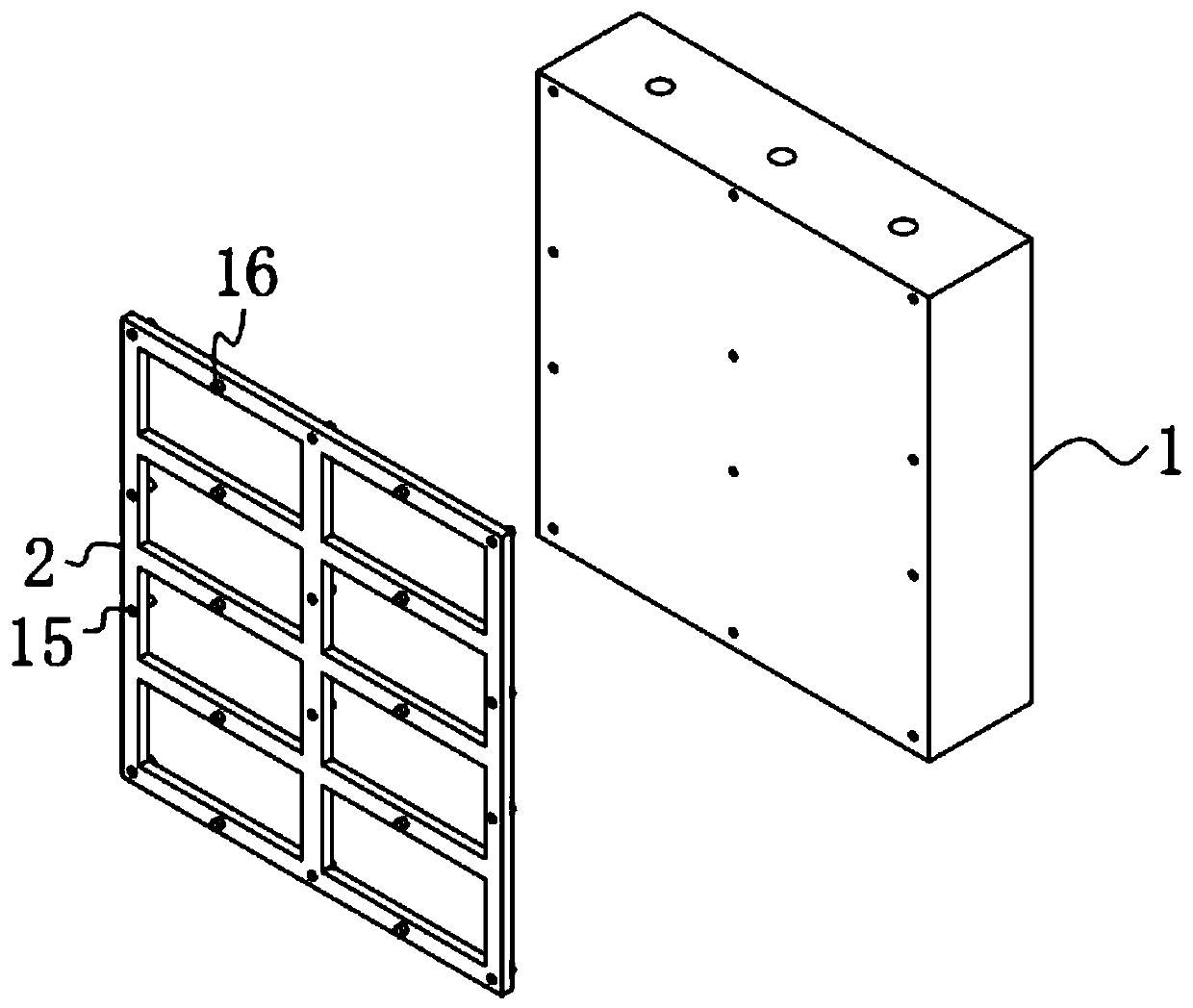

[0053] The first step is to pre-prepare a square fixed frame 2 whose size matches the building outer wall 1 according to the size of the building outer wall 1, and uniformly weld several first thickness benchmarks 16 on one side of the square fixed frame 2 and fix them on the square. Two vertical baffles 3 are welded symmetrically on both sides of the frame 2 and a horizontal baffle 4 is welded at the bottom of the square fixed frame 2;

[0054] In the second step, a scaffold is set up on one side of the outdoor surface of the building exterior wall 1, and several first installation holes 11 are provided with an electric drill on the outdoor surface of the building exterior wall 1 by means of the scaffold;

[0055] The third step is to use heat preservation nails 15 to cooperate with the first installation hole 11 to fix the square fixed frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com