Method for constructing external wall polyurethane insulation and panel for construction

A construction method and polyurethane technology, applied in the direction of thermal insulation, wall, formwork/formwork/work frame, etc., can solve the problems affecting the overall thermal insulation performance of the thermal insulation layer, the thickness of the thermal insulation layer is difficult to control, and the construction period is long. Operation, easy implementation and popularization and application, the effect of high wall flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

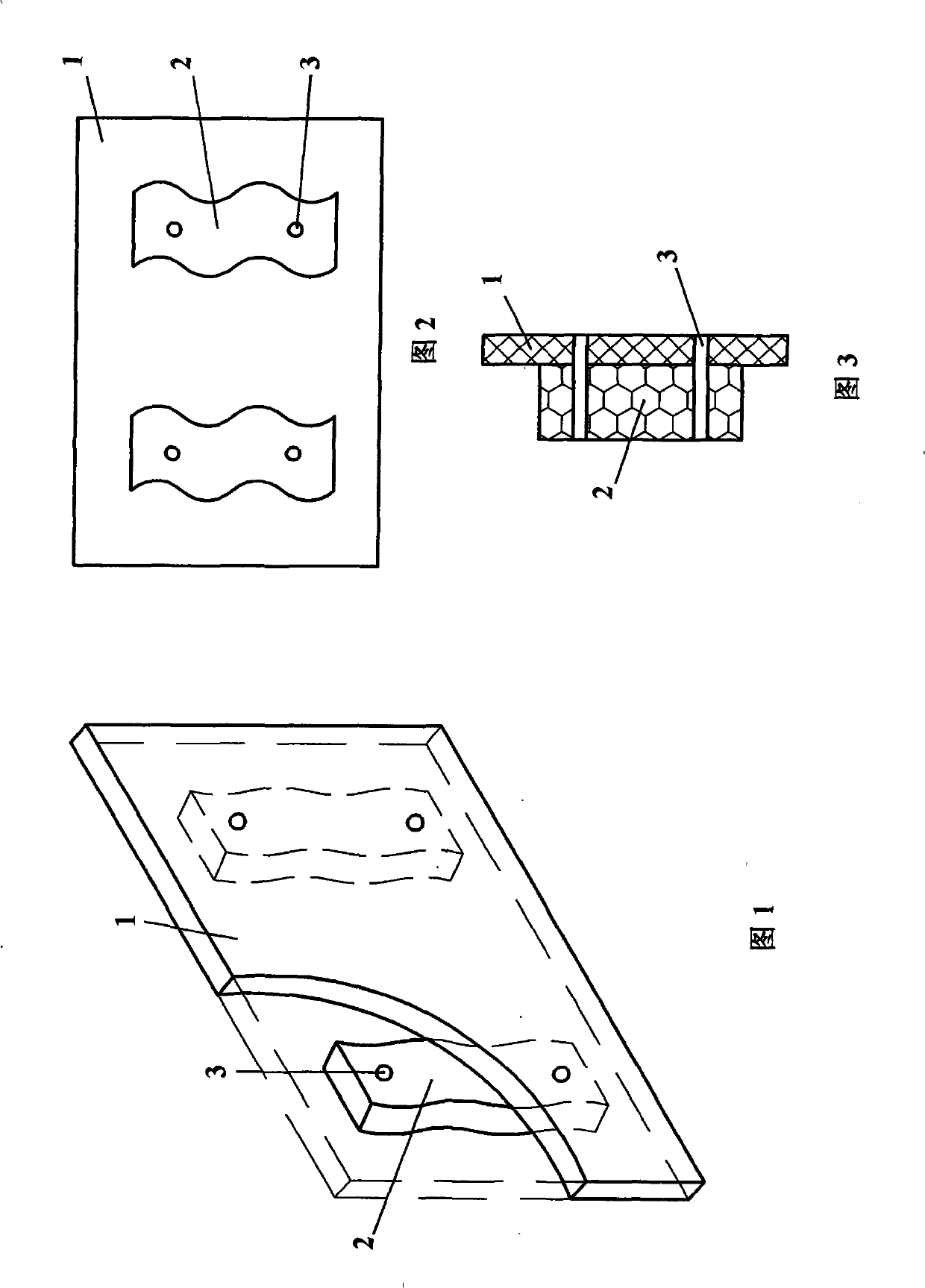

[0043] Embodiment 1: use calcium silicate board as panel prefabricated construction panel

[0044] First of all, according to the construction area where the external wall insulation is implemented, the thickness of the insulation layer is determined. In this embodiment, the thermal insulation construction of the external wall is carried out in Jilin area. The thickness of the thermal insulation layer should meet the requirements of the limit value of the heat transfer coefficient of the external wall when the local building energy saving is 65%. The thickness of the thermal insulation layer is determined to be 60 mm.

[0045] A calcium silicate board with an external dimension of 900×600×8 mm is selected as the panel, and a hyperboloid shape of 150×400 mm is selected for the positioning special-shaped parts, and the thickness is 60 mm. For this reason, prepare a special mold with the same shape as the hyperboloid positioning special-shaped piece with a thickness of 60 mm.

...

Embodiment 2-5

[0047] Embodiment 2-5: the preparation of special adhesive of the present invention

[0048] The weight ratio (unit: kilogram) of each embodiment raw material is shown in Table 1.

[0049] Preparation method: (taking Example 3 as an example, other examples are basically the same as Example 3 except that the amount of raw materials is different)

[0050] Mix 6 kg of vinyl acetate-ethylene copolymer emulsion and 4 kg of acrylic acid emulsion evenly, then mix with 10 kg of water, 20 kg of 42.5 ordinary portland cement, 10 kg of 30-50 mesh dry quartz sand, 40 kg 50-100 mesh dry quartz sand and 9 kg of methyl cellulose are mixed evenly, and then 0.8 kg of conventional defoamer and 0.2 kg of naphthalene-based early-strength water reducer are added to obtain 100 kg of special adhesive for the present invention.

[0051] Table 1

[0052] Example

[0053] 30-50 mesh dry quartz sand

Embodiment 6

[0054] Embodiment 6: Construction of exterior wall polyurethane insulation with calcium silicate board as panel

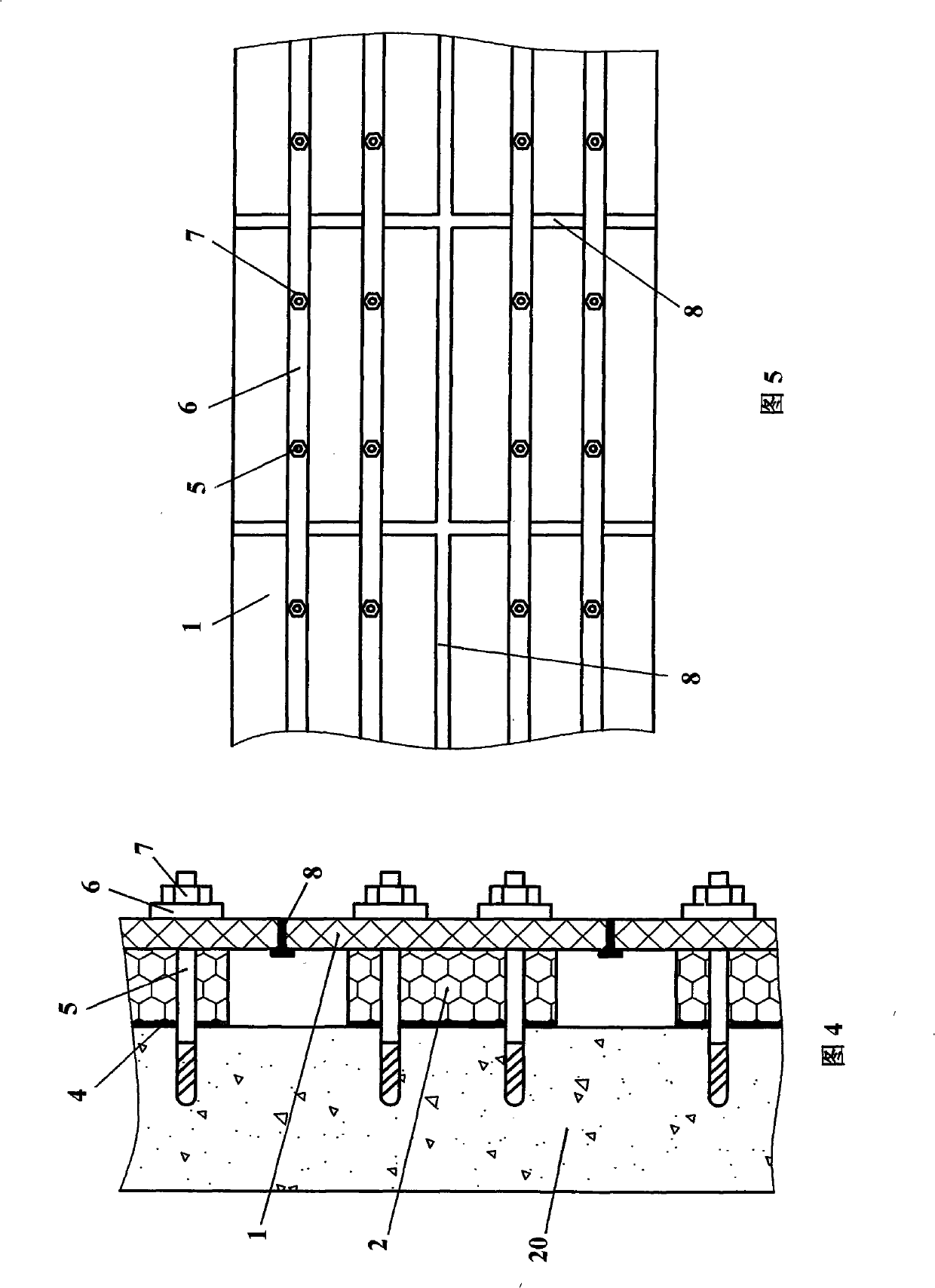

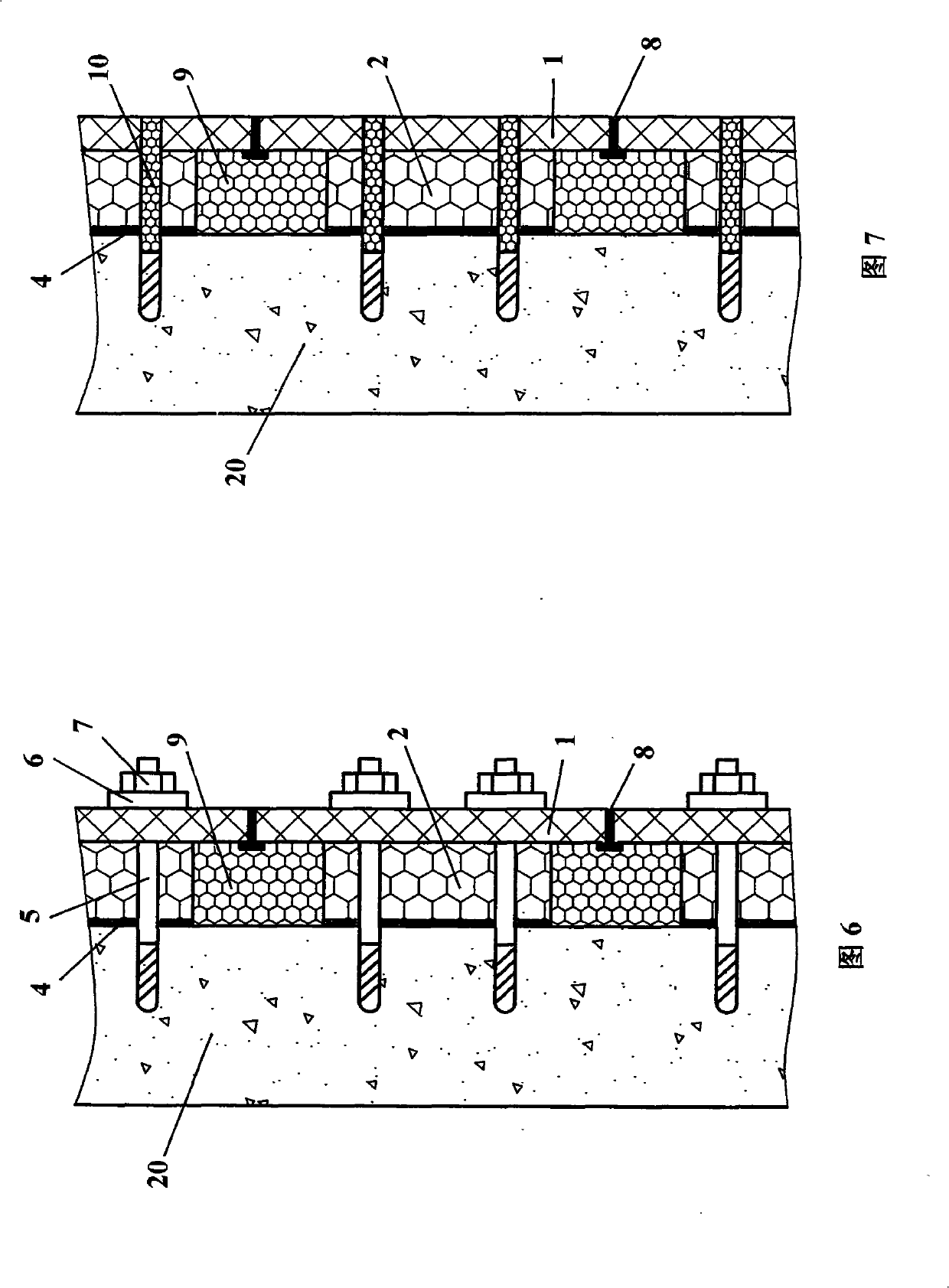

[0055] Referring to Figures 4, 5, 6 and 7, the construction steps of polyurethane insulation for exterior walls using calcium silicate boards as panels are as follows:

[0056] (1) On the positioning special-shaped part of the construction panel with the calcium silicate board prefabricated in embodiment 1, smear the special binding agent gained in embodiment 3, smear 2 times successively, and smear 1.5 millimeters thick every time.

[0057] (2) Use the special adhesive 4 applied on the positioning special-shaped parts to bond and fix each construction panel on the outer surface of the outer wall according to the designed position. Position the outer wall to drill holes, nail in the detachable anchor bolts 5 fixedly connected with the outer wall, and then install a strip-shaped adjustment steel backing plate 6 on the anchor bolts between the various construction pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com