Method for preparing personalized degradable metal stent or internal fixation device based on 3D printing

A metal bracket and 3D printing technology, applied in brackets, additive processing and other directions, can solve the problems of aluminum toxicity and sensitization, zinc alloy inability, poor mechanical properties of pure zinc, etc., to improve processing efficiency, reduce production costs, The effect of avoiding machining defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: Zn-1Mg alloy "S" shape bracket

[0064] (1) Structural analysis and modeling of degradable metal stents

[0065] ①The casting material is zinc alloy (Zn-1Mg alloy), which is made by melting pure zinc (99.99+%) and pure magnesium (99.99+%). The melting point is around 420°C. Based on the designed support structure and the technical requirements for low-melting thin-wall parts casting, it is determined that the casting process used is lost-wax casting;

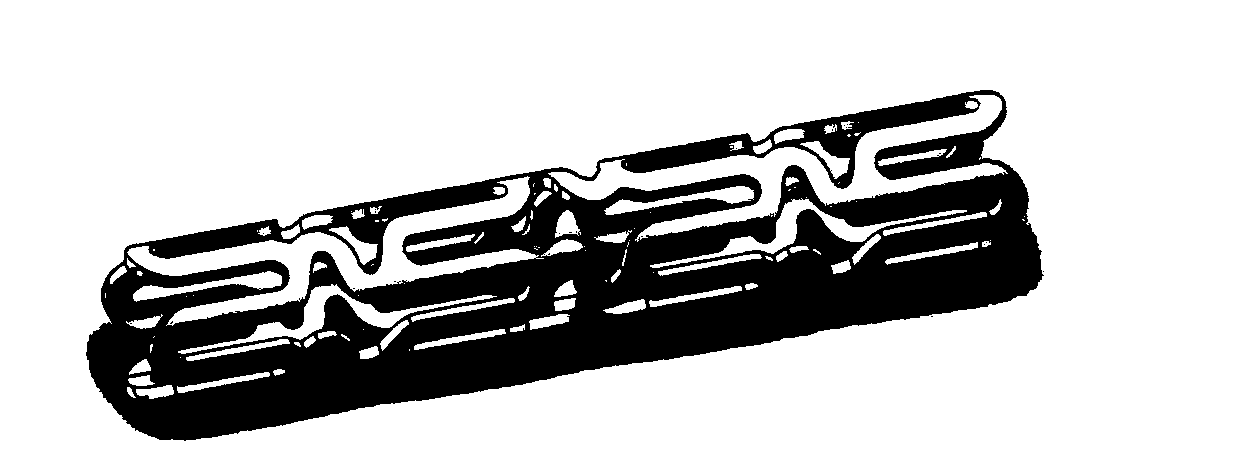

[0066] ②According to coronary angiography, measure the diameter of the lesion vessel by QCA (qualitative comparative analysis) technology, obtain the shape data of the lesion vessel, and design the personalized degradable stent. The diameter of the diseased blood vessel was measured to be 10mm, figure 1 The "S"-shaped scaffold structure suitable for the patient's lesion determined by three-dimensional reconstruction is given;

[0067] ③Establish the 3D model of the wax model of the intravascular stent in ...

Embodiment 2

[0080] Embodiment 2: Zn-1Li alloy rhombic grid support

[0081] (1) Structural analysis and modeling of degradable metal stents

[0082] ①The casting material is zinc alloy (Zn-1Li alloy), which is made of pure zinc (99.99+%) and pure lithium (99.99+%) through vacuum melting. The melting point is around 420°C. According to the designed support structure and the technical requirements for low-melting thin-wall casting, it is determined that the casting process used is lost-wax casting;

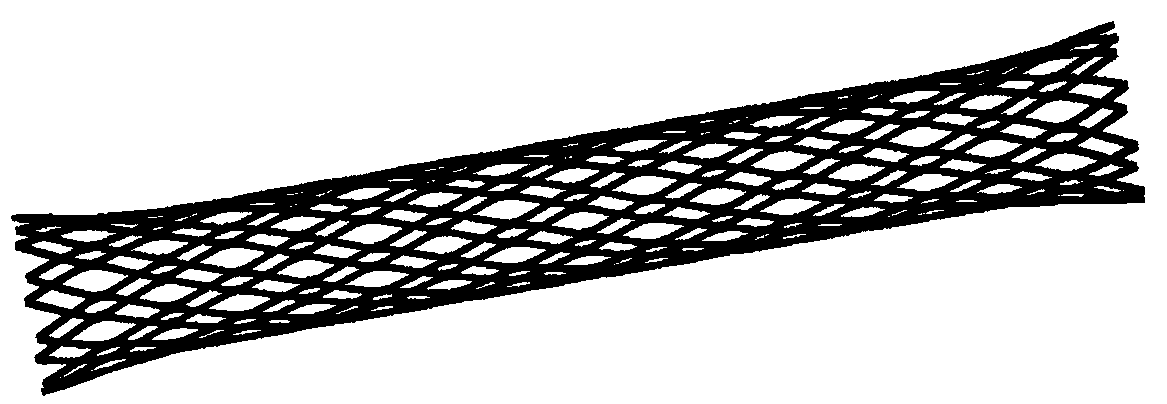

[0083] ②According to coronary angiography, QCA technology is used to obtain the morphological data of diseased blood vessels, and the design of personalized degradable stents is carried out. The diameter of the diseased blood vessel was measured to be 10mm, figure 2 A diamond-shaped grid stent structure with slightly larger openings at both ends determined by three-dimensional reconstruction is given;

[0084] ③ Establish a 3D model of the wax model of the intravascular stent in the compute...

Embodiment 3

[0097] Embodiment 3: Zn-4Cu alloy cone structure and special-shaped bifurcation structure support

[0098] (1) Structural analysis and modeling of degradable metal stents

[0099] ①The casting material is zinc alloy (Zn-4Cu alloy), which is made by melting pure zinc (99.99+%) and H62 brass (Cu-38wt%Zn). mm, according to the designed support structure and the technical requirements for low-melting thin-wall parts casting, it is determined that the casting process used is lost-wax casting;

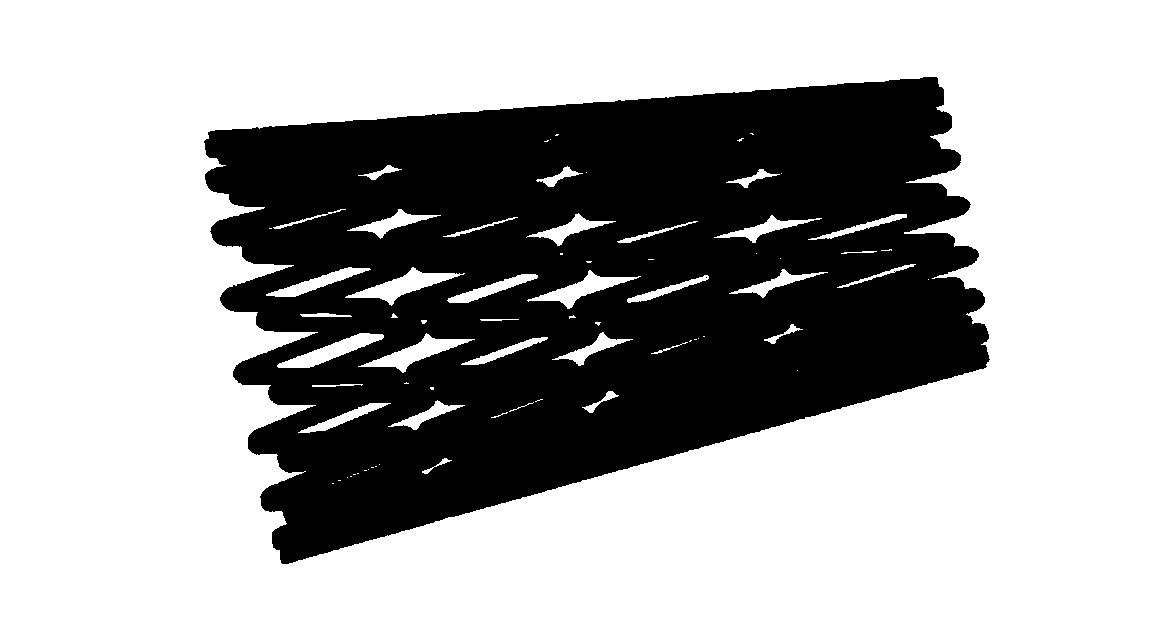

[0100] ②According to coronary angiography, QCA technology is used to obtain the morphological data of diseased blood vessels, and the design of personalized degradable stents is carried out. The measured shape of the two diseased coronary vessels is not the traditional single cylindrical shape, one is a conical structure, the diameter of the large end is 3cm, the diameter of the small end is 2cm, and the length of the stent is 5cm; the other is abnormal Bifurcation structure, the shape of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com