Assembling method for bogie wheel disc assembly of tracked vehicle

An assembly method and a technology of road wheels, which are applied in the direction of wheel assembly equipment, wheels, vehicle parts, etc., can solve the problems of easy detachment of steel wear rings, walking failures, unstable product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

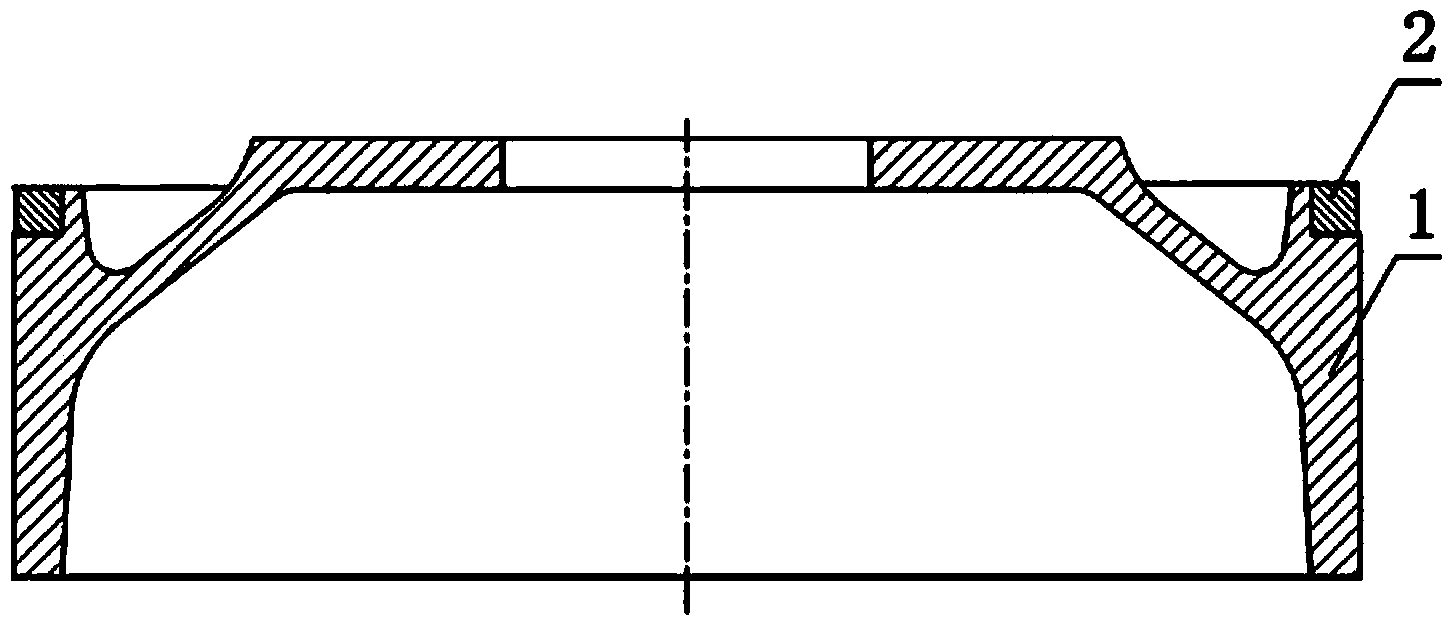

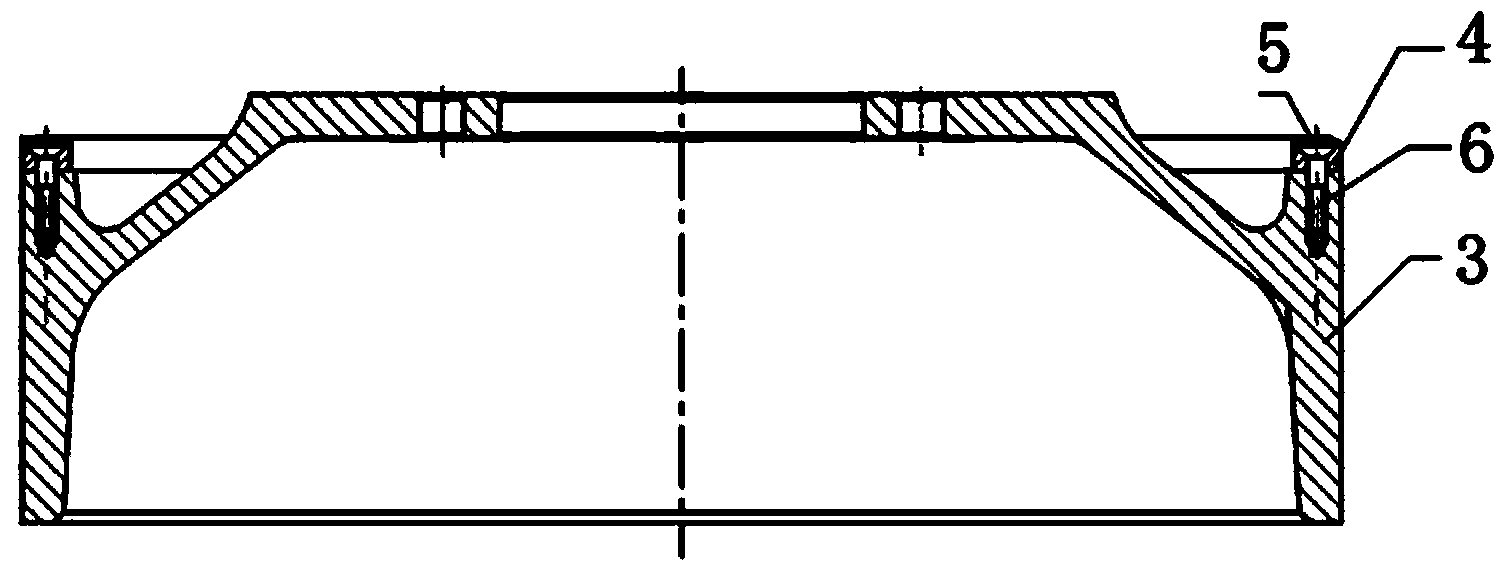

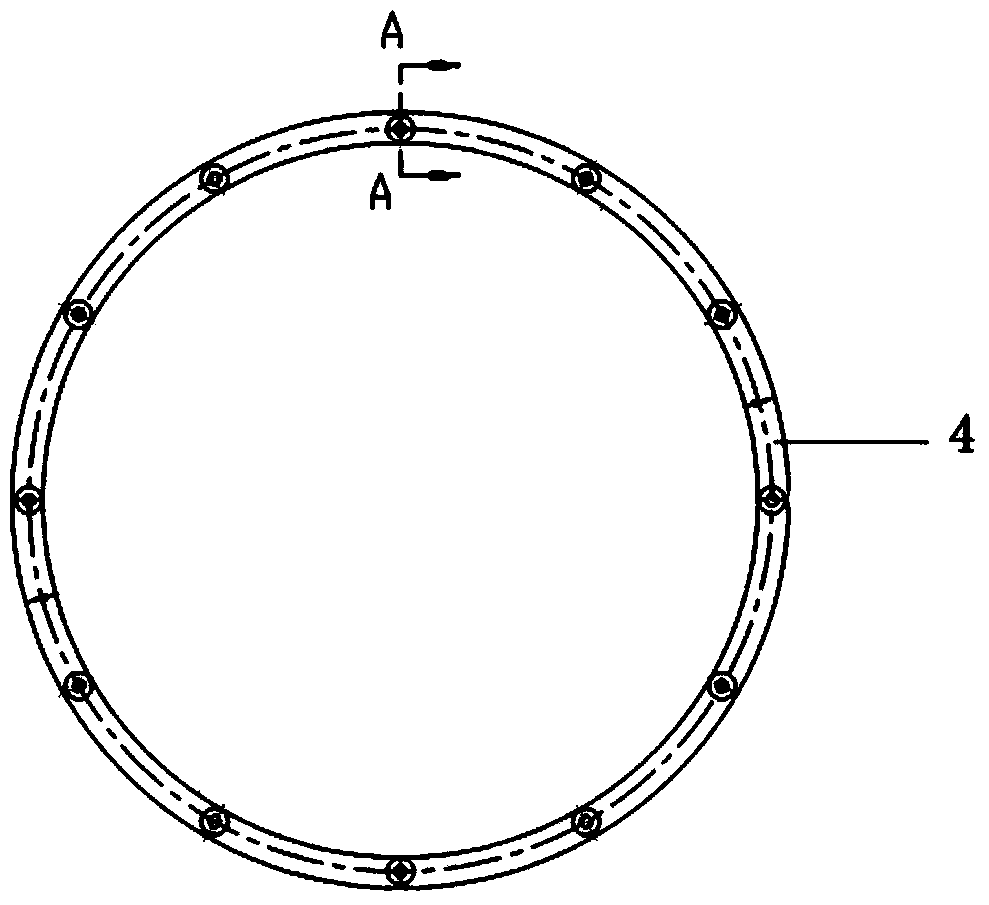

[0022] refer to Figure 2 to Figure 4 , the assembly method of the tracked vehicle load wheel assembly of the present invention adopts a special connection method of threaded mechanical connection plus welding, fastening and airtight, so that the load wheel and the wear-resistant steel ring are firmly combined into one body to form the load wheel assembly. Specifically include the following steps:

[0023] (1), manufacture wear-resistant steel ring 4 blanks by any method, and process to required size, wear-resistant steel ring 4 is preferably made of 38CrSi steel. Then offer the connection concave hole on the wear-resistant steel ring 4, or directly form the connection concave hole when manufacturing the wear-resistant steel ring 4 blank. The angle α of the opening of the connecting recess is preferably 90°.

[0024] (2) Use any method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com