Lung-heat clearing glutinous rice ball and making method thereof

A technology of glutinous rice balls and glutinous rice, which is applied in food ingredients as taste improvers, food coating, food science, etc. It can solve problems such as cracking, poor taste, and consumer distress, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

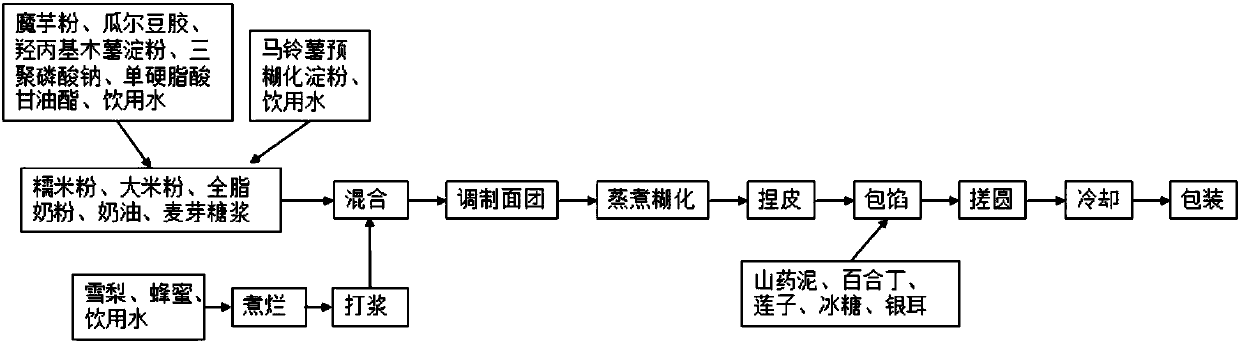

Method used

Image

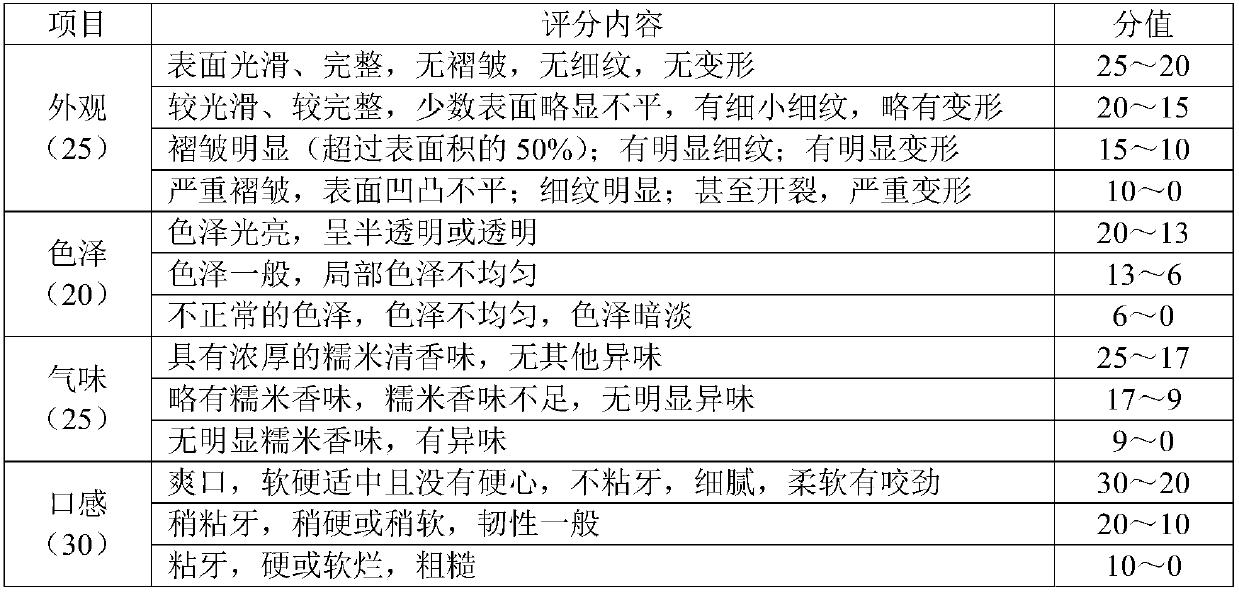

Examples

Embodiment 1

[0115] 1. Formula

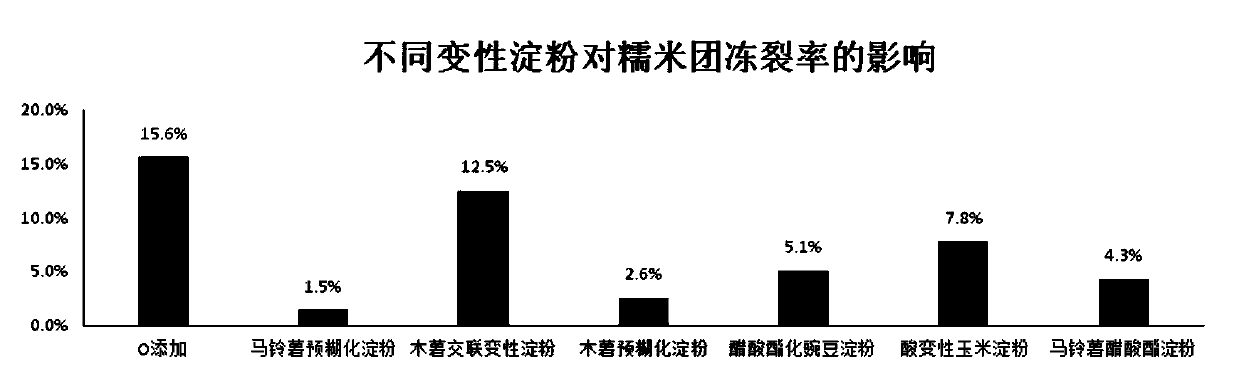

[0116] Glutinous rice skin: glutinous rice flour 33wt%, rice flour 7wt%, whole milk powder 2wt%, maltose syrup 15wt%, cream 2wt%, potato pregelatinized starch 2wt%, improver 0.6wt% (guar gum 15wt%, konjac Flour 5wt%, Hydroxypropyl Tapioca Starch 60wt%, Glyceryl Monostearate 10wt%, Sodium Tripolyphosphate 10wt%), Sydney Honey Syrup 38.4wt% (Sydney 20wt%, Honey 5wt%, Drinking Water 75wt%)

[0117] Filling: 30wt% yam, 10wt% lily, 20wt% lotus seed, 10wt% rock sugar, 10wt% white fungus, 20wt% water

[0118] 2. Production method

[0119] 2.1 Making glutinous rice skin:

[0120] Modified starch pretreatment: Weigh potato pregelatinized starch, soak and stir (400rpm) with 10 times 20°C drinking water, dissolve for 10min, and obtain starch slurry.

[0121] Improver swelling: Add 20 times the weight of drinking water at 25°C to the improver, stir and swell at 800 rpm for 5 minutes to obtain a swollen improver.

[0122] Production of Sydney honey pulp: Peel, core,...

Embodiment 2

[0136] 1. Formula

[0137] Glutinous rice skin: glutinous rice flour 28wt%, rice flour 12wt%, whole milk powder 3wt%, maltose syrup 12.1wt%, cream 2wt%, potato pregelatinized starch 2.5wt%, improver 0.4wt% (guar gum 15wt% , konjac flour 5wt%, hydroxypropyl tapioca starch 60wt%, glyceryl monostearate 10wt%, sodium tripolyphosphate 10wt%), Sydney honey syrup 40wt% (Sydney 20wt%, honey 5wt%, drinking water 75wt%)

[0138] Filling: 33wt% yam, 5wt% lily, 22wt% lotus seed, 12wt% rock sugar, 8wt% white fungus, 20wt% water

[0139] 2, the preparation method is the same as embodiment 1.

Embodiment 3

[0141] 1. Formula

[0142] Glutinous rice skin: glutinous rice flour 38wt%, rice flour 2wt%, whole milk powder 1wt%, maltose syrup 17.7wt%, cream 2wt%, potato pregelatinized starch 1.5wt%, improver 0.8wt% (guar gum 15wt% , konjac flour 5wt%, hydroxypropyl tapioca starch 60wt%, glyceryl monostearate 10wt%, sodium tripolyphosphate 10wt%), Sydney honey syrup 37wt% (Sydney 20wt%, honey 5wt%, water 75wt%)

[0143] Filling: 25wt% yam, 15wt% lily, 14wt% lotus seed, 14wt% rock sugar, 12wt% white fungus, 20wt% water

[0144] 2, the preparation method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com