Crescent connecting assembly

A technology for connecting components and crescents, applied in the direction of connecting components, thin plate connections, mechanical equipment, etc., can solve the problems of troublesome assembly and disassembly, high labor intensity, etc., and achieve the effect of complete surface, ingenious structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

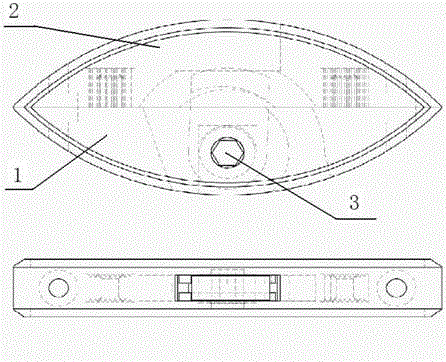

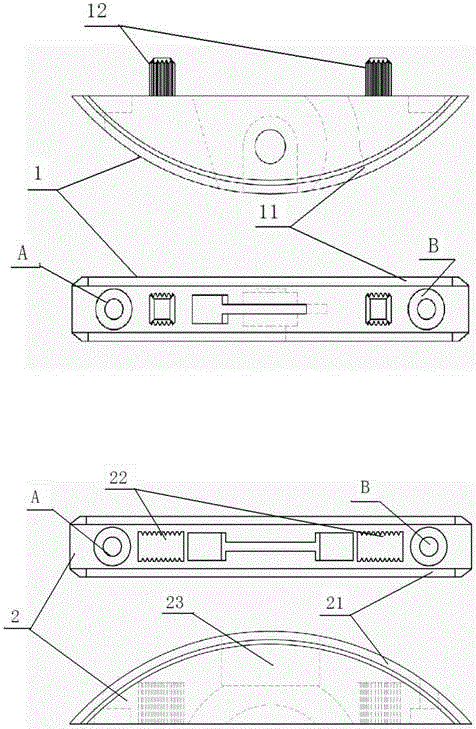

[0014] Such as Figures 1 to 5 As shown, a crescent connection assembly includes: a connection head 1 , a connection seat 2 and a lock card 3 .

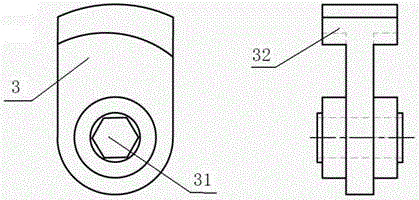

[0015] Such as figure 2 As shown, one end of the connector is arc-shaped with convex grooves 11 on both sides, and the other end is a plane with more than one positioning boss 12, and an angle-adjustable locking card 3 is provided in the middle; as figure 2 As shown, one end of the connection seat is arc-shaped with convex grooves 21 on both sides, and the other end is a plane with more than one positioning concave platform 22, and an accommodating cavity 23 that can accommodate the lock card 3 is provided in the middle; Figures 3 to 5 As shown, the locking card 3 is fixed in the middle of the connector 1, and the hexagonal hole 31 at the tail end of the locking card is rotated with the hexagonal wrench 4 to rotate the locking card head 32, so as to realize the connection or separation of the connector 1 and the connecting seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com