Suspended formwork pouring method for concrete foundation steps

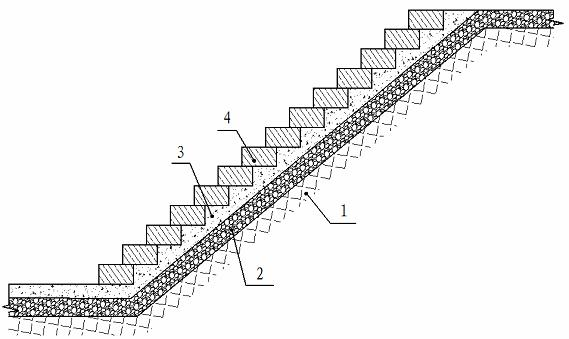

A technology of concrete foundation and pouring concrete, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of difficult positioning and control of cement mortar bonding layer, adverse effects of step structure and strength, unfavorable stone laying operation, etc. Achieve regular structure, improve strength and structural stability, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better explain the present invention and understand it better, the present invention will be described in more detail below through specific embodiments in conjunction with the accompanying drawings.

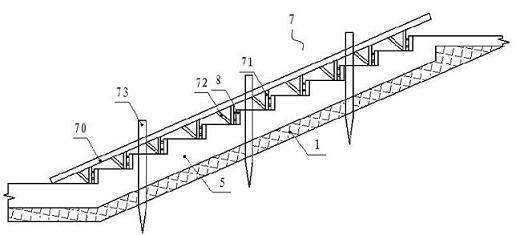

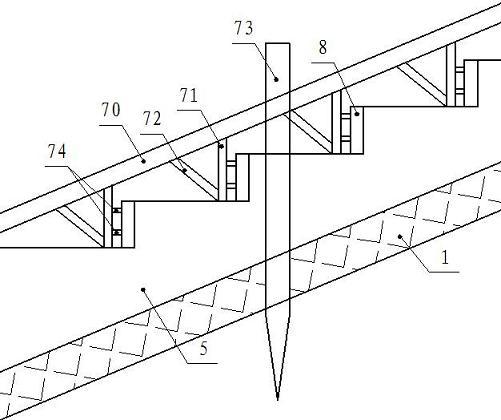

[0027] see figure 2 and image 3 , the present invention provides a hanging form for pouring concrete foundation steps, comprising one or several formworks 7, said formwork comprising at least one longitudinal beam 70 and a plurality of structural units sequentially distributed along said longitudinal beam, The structural unit includes a vertical formwork frame 71 for installing the vertical formwork 8 and an oblique reinforcing rib 72 for fixing the vertical formwork frame. One end of the vertical formwork frame is fixedly connected to the longitudinal beam, so Both ends of the oblique reinforcing ribs are respectively fixedly connected with the longitudinal beam and the vertical formwork frame, and a stable triangular structure is formed between the three....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com