Railroad business line box bridge extension construction method

A construction method and wire box technology, which are applied in the construction field of long box-shaped bridges on railway business lines, can solve the problems of safety hazards in protective measures, difficulty in dismantling the eight-shaped wing wall, and large amount of protective engineering, so as to achieve high construction efficiency and short construction period , The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

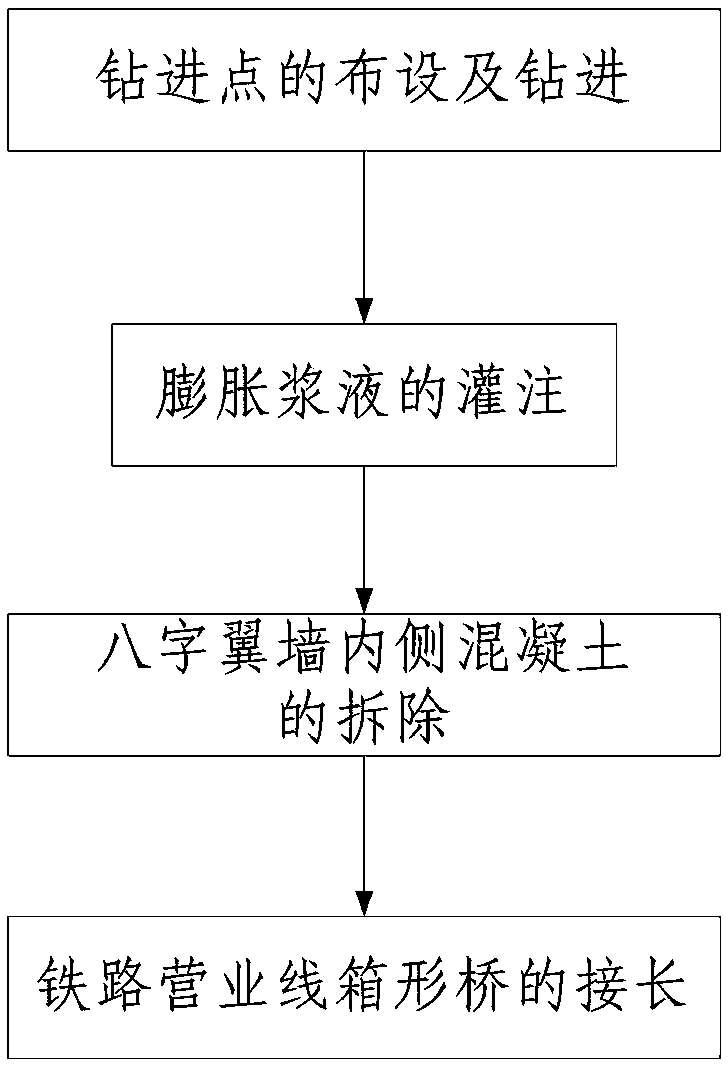

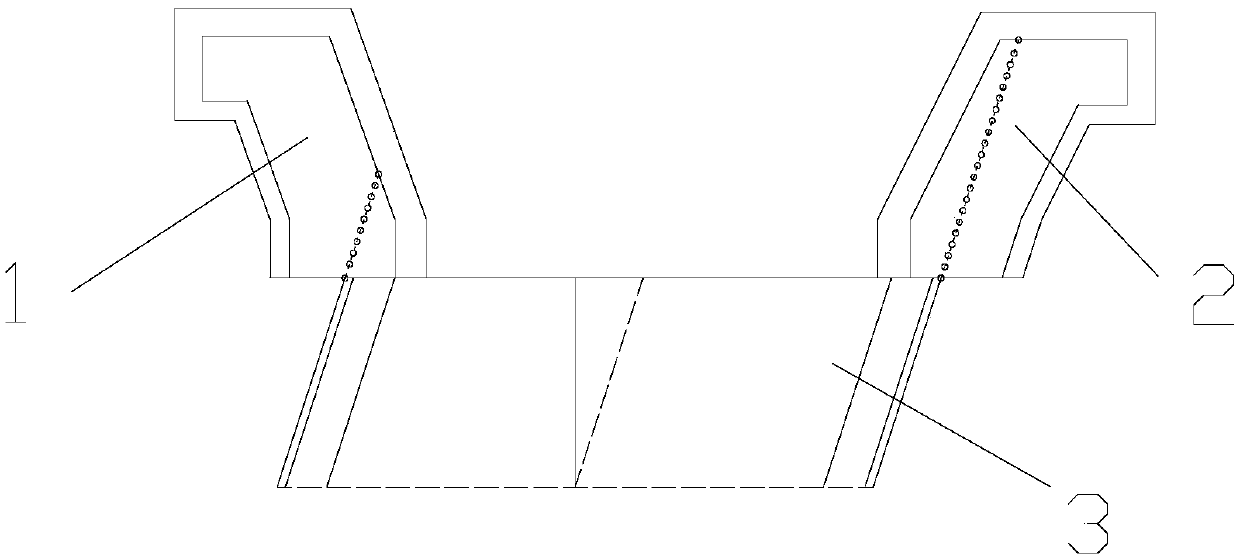

[0067] like figure 1 and figure 2 Shown is a long construction method for box-shaped bridges on railway business lines, the splayed wing walls include two symmetrically arranged retaining walls, and the two retaining walls are respectively the first retaining wall 1 and the second retaining wall The earth wall 2, the first retaining wall 1 and the second retaining wall 2 are fixedly connected to both sides of the main body foundation 3 of the box bridge, comprising the following steps:

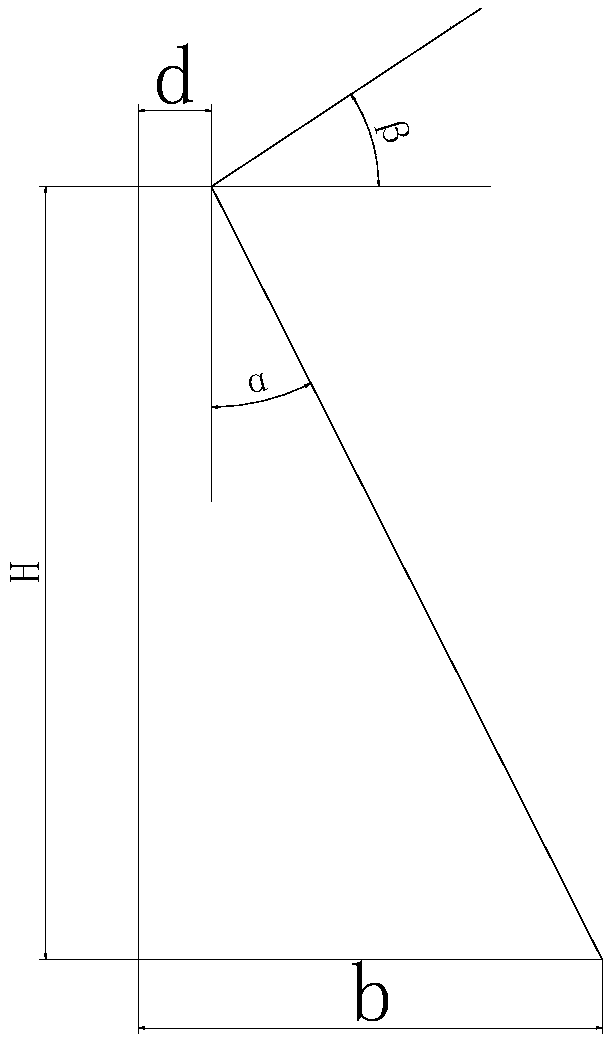

[0068] Step 1. Layout and drilling of drilling points:

[0069] Step 101, arranging a plurality of first drilling points at intervals on the top of the first retaining wall 1, the connection line of the plurality of first drilling points and the side edge of the main body foundation 3 of the box-shaped bridge Extension cord overlap;

[0070] Step 102, arranging a plurality of second drilling points at intervals on the top of the second retaining wall 2, the connection line of the plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com