Adjustable formwork system for small-size deformation joint construction

A technology of formwork system and deformation joints, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and preparation of building components on site, which can solve the problem of inability to accurately ensure the size and Problems such as verticality, potential safety hazards, and long construction preparation time can avoid the difficulty of upper and lower safety protection and dynamic management, improve safety and reliability, and shorten the preparation and formwork time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

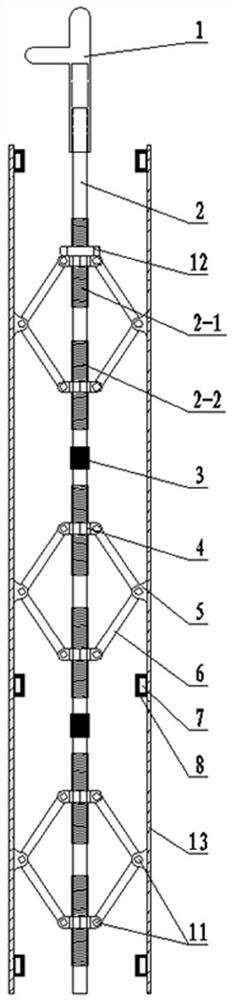

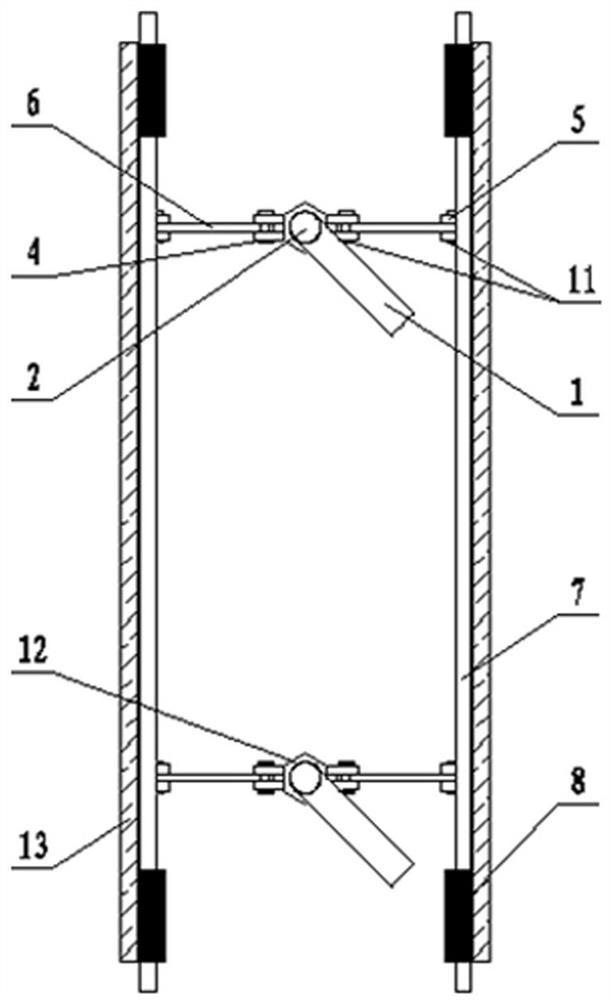

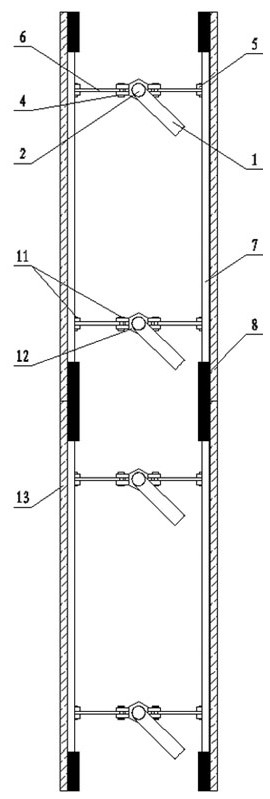

[0022] Such as figure 1 , 2 As shown in and 3, the present invention includes a handle 1, a screw rod 2, a connecting sleeve 3, a screw nut 4, an ear plate 5, a pull plate 6, and a steel formwork 13, and the screw rod 2 is provided with forward-rotating thread segments 2 at intervals along the axial direction. -1 and anti-rotation thread section 2-2, the connecting sleeve 3 is fixedly connected with the upper and lower adjacent screw rods 2, the handle 1 is arranged on the top of the top screw rod 2, and the screw nuts 4 are respectively arranged on the same screw rod 2 Corresponding threaded holes are provided on the forward-rotating threaded section 2-1 and the rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com